Microalgae pigment and its extraction method

An extraction method and technology of microalgae, applied in the direction of chemical instruments and methods, organic chemistry, organic dyes, etc., can solve the problems of low purity of microalgae pigments, complicated process routes, and low cost, so as to facilitate industrial production and simplify extraction Process, the effect of reducing the amount of usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

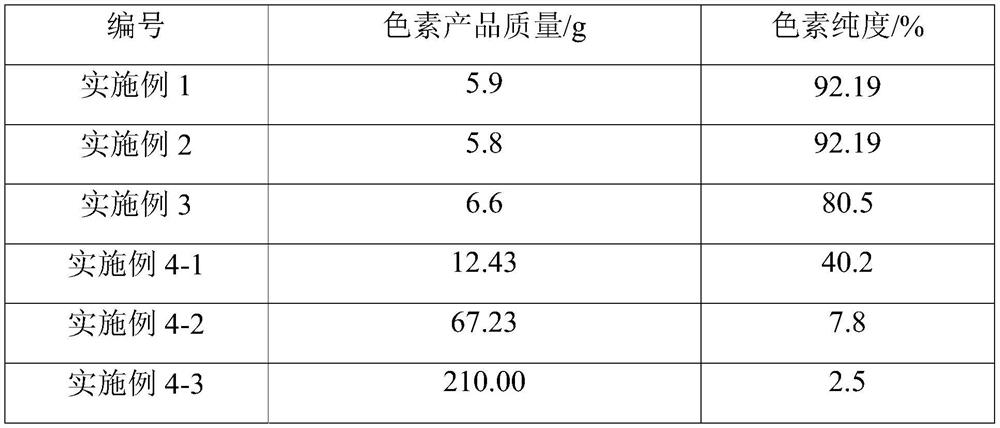

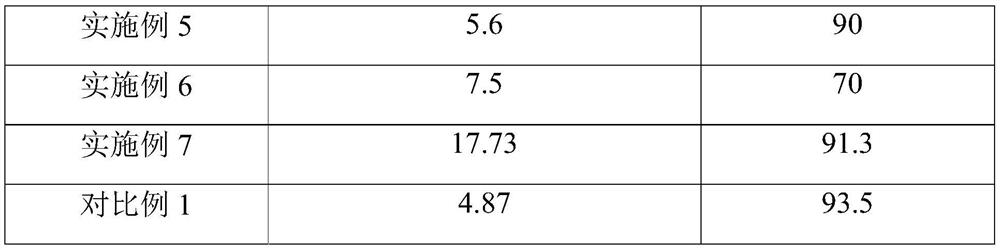

Embodiment 1

[0057] This example is used to illustrate the extraction method of fucoxanthin provided by the present invention

[0058] 1) take 500g of diatom powder, use an ultra-fine pulverizer to pulverize the algae powder, and the obtained diatom powder pulverized product has a particle size of 0.5-10 μm;

[0059] 2) in the silica gel chromatography column, add the mixed solvent (n-hexane and ethyl acetate volume ratio is 1:1) that n-hexane and ethyl acetate are formed and use the peristaltic pump to rinse the silica gel column at high speed;

[0060] 3) Add the pulverized algal flour obtained in step 1) into a chromatography column, add a mixed solvent composed of n-hexane and ethyl acetate for elution, and the volume ratio of n-hexane and ethyl acetate is 1:1.

[0061] 4) Collect the eluent containing red components in the chromatographic column, remove the solvent by nitrogen blowing, and then perform vacuum drying to obtain a pigment product; the nitrogen flow rate of the nitrogen b...

Embodiment 2

[0065] This example is used to illustrate the extraction method of fucoxanthin provided by the present invention

[0066] 1) take 500g of diatom powder, use an ultra-fine pulverizer to pulverize the algae powder, and the obtained diatom powder pulverized product has a particle size of 0.5-10 μm;

[0067] 2) Silica gel was charged into the chromatographic column, and the mixed solvent formed by adding n-hexane and ethyl acetate (n-hexane and ethyl acetate volume ratio was 1:0.3) carried out column compression;

[0068] 3) Add the pulverized algal flour obtained in step 1) into a chromatography column, add a mixed solvent composed of n-hexane and ethyl acetate for elution, and the volume ratio of n-hexane and ethyl acetate is 1:0.3.

[0069] 4) Collect the eluent containing red components in the chromatographic column, remove the solvent by nitrogen blowing, and then perform vacuum drying to obtain a pigment product; the nitrogen flow rate of the nitrogen blowing method is 5.0 m...

Embodiment 3

[0072] This example is used to illustrate the extraction method of fucoxanthin provided by the present invention

[0073] 1) take 500g of diatom powder, use an ultra-fine pulverizer to pulverize the algae powder, and the obtained diatom powder pulverized product has a particle size of 0.5-10 μm;

[0074] 2) Silica gel is charged in the chromatography column, and the mixed solvent (n-hexane and ethyl acetate volume ratio is 1:3) formed by adding n-hexane and ethyl acetate is added to carry out column compression;

[0075] 3) Add the pulverized algal flour obtained in step 1) to a chromatography column, add a mixed solvent composed of n-hexane and ethyl acetate for elution, and the volume ratio of n-hexane and ethyl acetate is 1:3.

[0076] 4) Collect the eluent containing red components in the chromatographic column, remove the solvent by nitrogen blowing, and then perform vacuum drying to obtain a pigment product; the nitrogen flow rate of the nitrogen blowing method is 0.5 mL...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com