A kind of immersion cooling fluid and its preparation method

A cooling fluid, immersion technology, applied in chemical instruments and methods, heat exchange materials, etc., can solve the problems of high local temperature and high fault tolerance of servers, and achieve high thermal conductivity, high dielectric strength and simple preparation process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] A method for preparing an immersion cooling fluid, comprising the following steps:

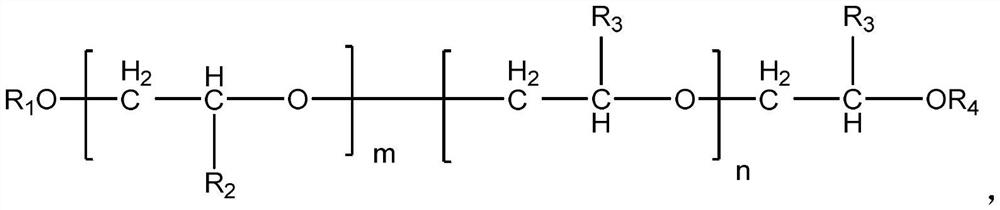

[0037] A. Weigh raw materials according to the following parts by weight: perfluoropropyl methyl ether 10-20, trans-1,2-dichloroethylene 1-5, isopropanol 1-5, end-capped polyether 70-88; Preferably, the end-capped polyether structure is:

[0038]

[0039] In the formula, m=0~10, n=0~5, m and n are not zero at the same time, R 1 for hydrogen or C 1 ~C 4 alkanes; R 2 is hydrogen or methyl, R 3 for C 2 ~C 5 alkanes, R 4 for where r is hydrogen, C 1 -C 6 Alkyl or C 1 -C 6 cycloalkyl.

[0040] Preferably, the purity of the perfluoropropyl methyl ether is >99%; the purity of the trans-1,2-dichloroethylene is >99.5%; and the purity of the isopropanol should be >99%.

[0041] B. Add perfluoropropyl methyl ether, trans-1,2-dichloroethylene, and isopropanol into the reaction kettle at 20-60°C under nitrogen, and stir for 10-30 minutes to form solution 1;

[0042] C. Add the end...

Embodiment 1

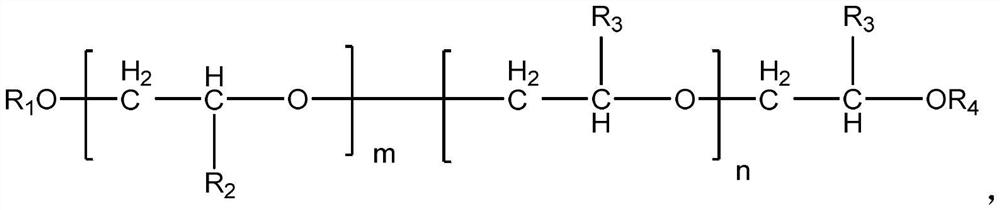

[0044] Embodiment 1, an immersion cooling fluid, including the following raw materials in parts by weight (this embodiment uses grams as the unit): perfluoropropyl methyl ether 10, trans-1,2-dichloroethylene 2.5, isopropyl Alcohol 3, end-capped polyether 84.5. Wherein, the end-capped polyether structure is:

[0045]

[0046] The preparation method of above-mentioned immersion type cooling fluid comprises the following steps:

[0047]A. Weigh raw materials: 10 grams of perfluoropropyl methyl ether, 2.5 grams of trans-1,2-dichloroethylene, 3 grams of isopropanol, and 84.5 grams of blocked polyether; wherein, the perfluoropropyl The purity of methyl ether is >99%; the purity of the trans-1,2-dichloroethylene is >99.5%; the purity of the isopropanol should be >99%.

[0048] B. Add 10 grams of perfluoropropyl methyl ether, 2.5 grams of trans-1,2-dichloroethylene, and 3 grams of isopropanol into the reaction kettle at 20°C under nitrogen gas, and stir for 10 minutes to form sol...

Embodiment 2

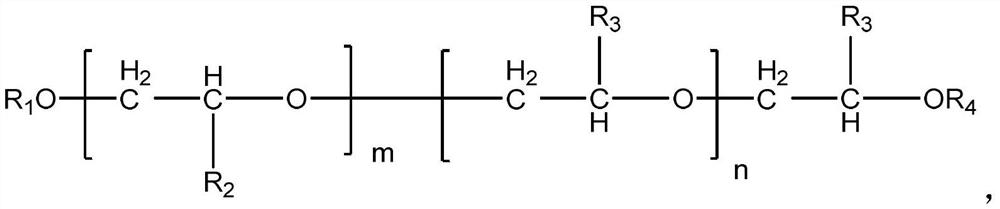

[0050] Embodiment 2, an immersion cooling fluid, comprising the following raw materials in parts by weight (this embodiment uses grams as the unit): perfluoropropyl methyl ether 20, trans-1,2-dichloroethylene 5, isopropyl Alcohol 5, end-capped polyether 70. Wherein, the end-capped polyether structure is:

[0051]

[0052] The preparation method of above-mentioned immersion cooling fluid comprises the following steps:

[0053] A. Weigh raw materials: 20 grams of perfluoropropyl methyl ether, 5 grams of trans-1,2-dichloroethylene, 5 grams of isopropanol, and 70 grams of blocked polyether; wherein, the perfluoropropyl The purity of methyl ether is >99%; the purity of the trans-1,2-dichloroethylene is >99.5%; the purity of the isopropanol should be >99%.

[0054] B. Add 20 grams of perfluoropropyl methyl ether, 5 grams of trans-1,2-dichloroethylene, and 5 grams of isopropanol into the reaction kettle at 60°C under nitrogen gas, and stir for 30 minutes to form solution 1;

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com