Patents

Literature

75 results about "Dichloroethylenes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Toxic chlorinated unsaturated hydrocarbons. Include both the 1,1- and 1,2-dichloro isomers. Both isomers are toxic, but 1,1-dichloroethylene is the more potent CNS depressant and hepatotoxin. It is used in the manufacture of thermoplastic polymers.

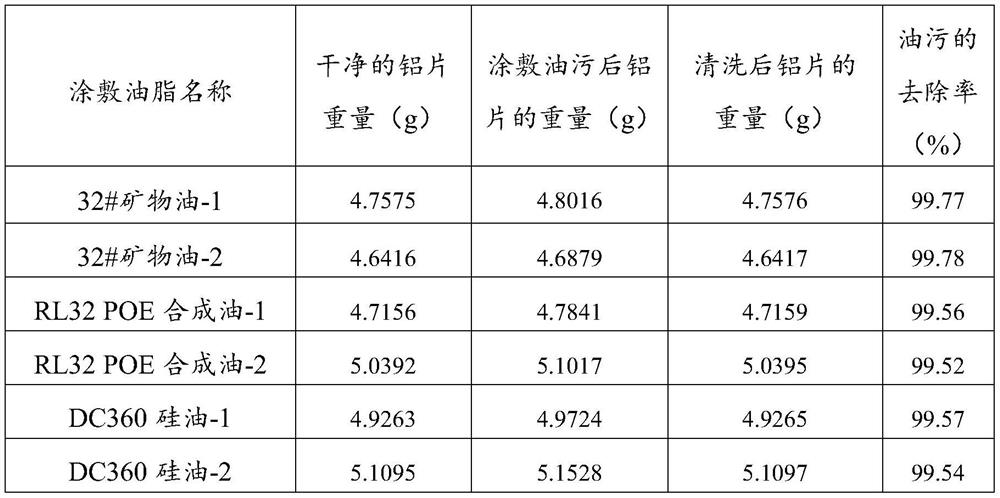

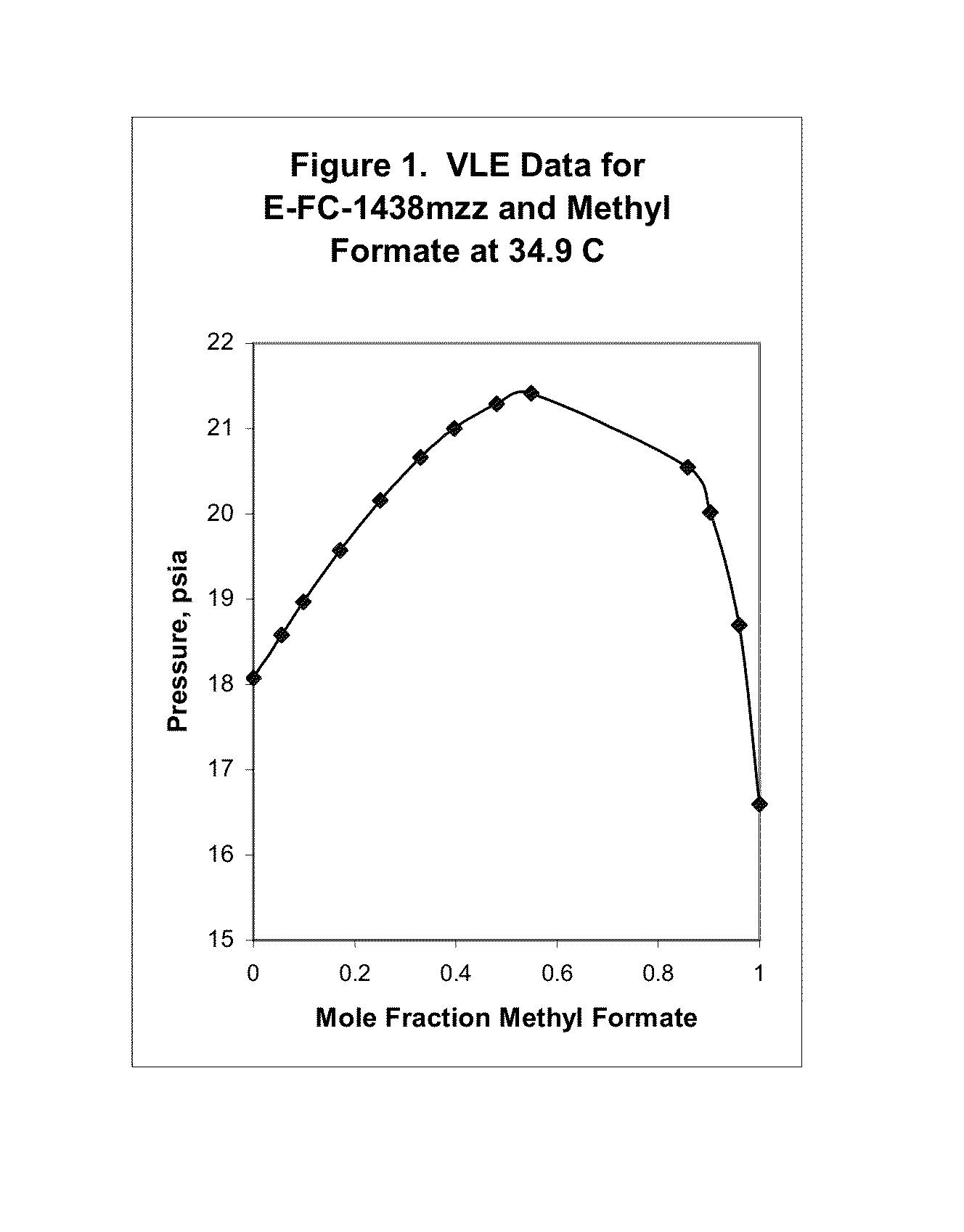

Azeotropic and azeotrope-like compositions of e-1,1,1,4,4,4-hexafluoro-2-butene

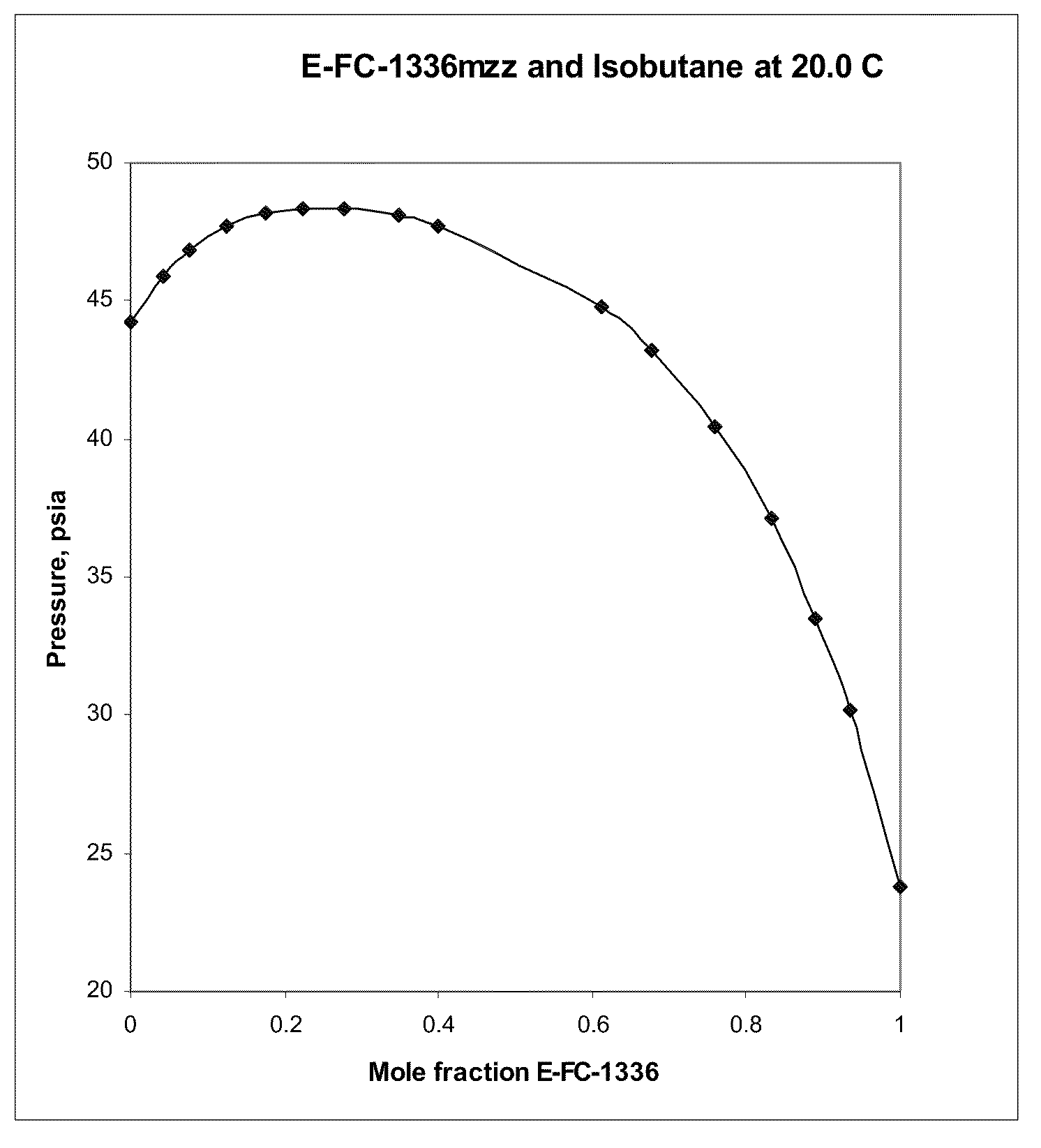

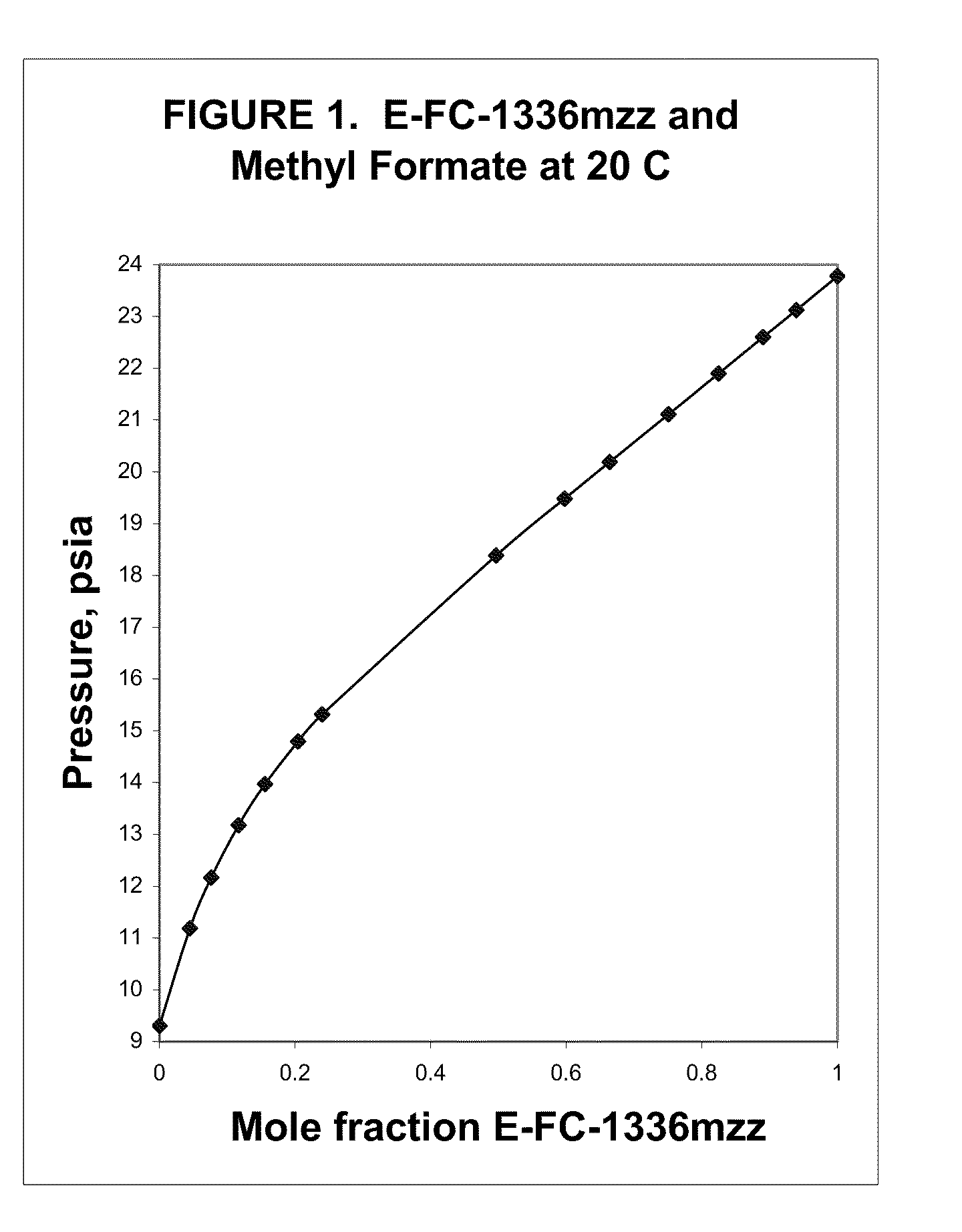

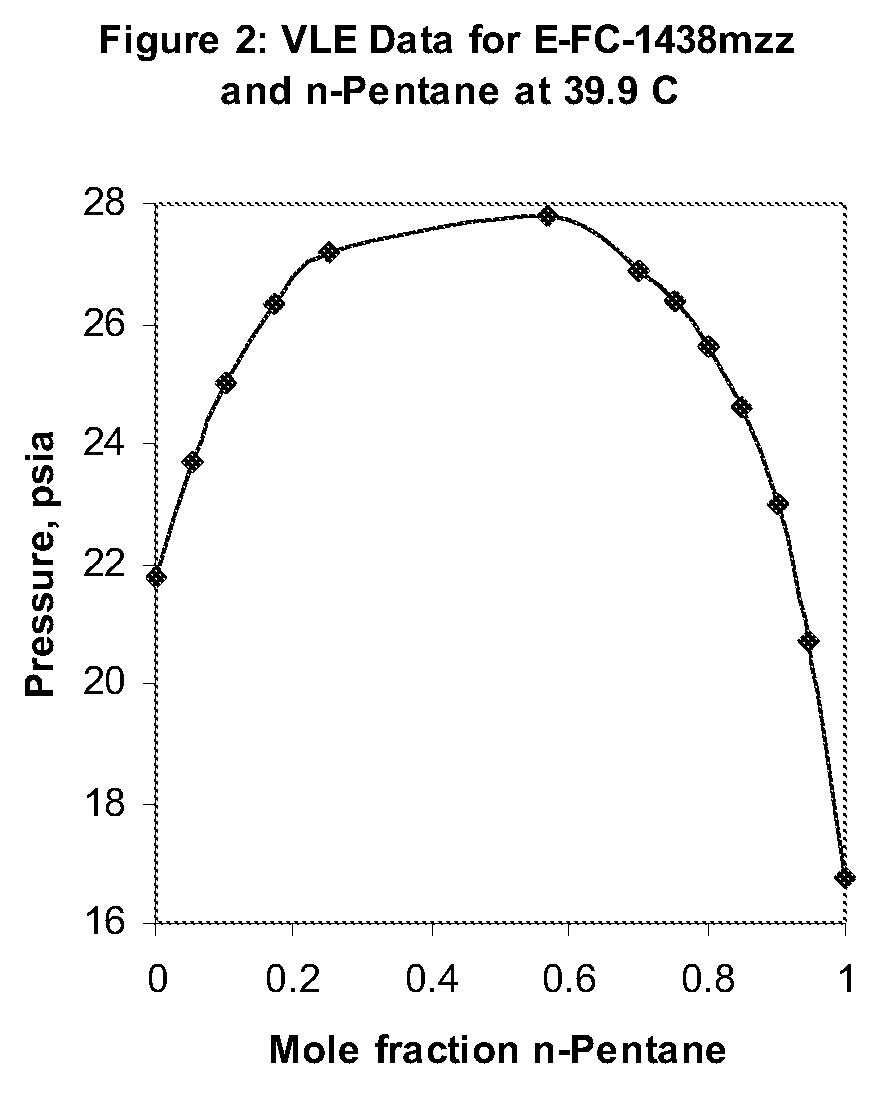

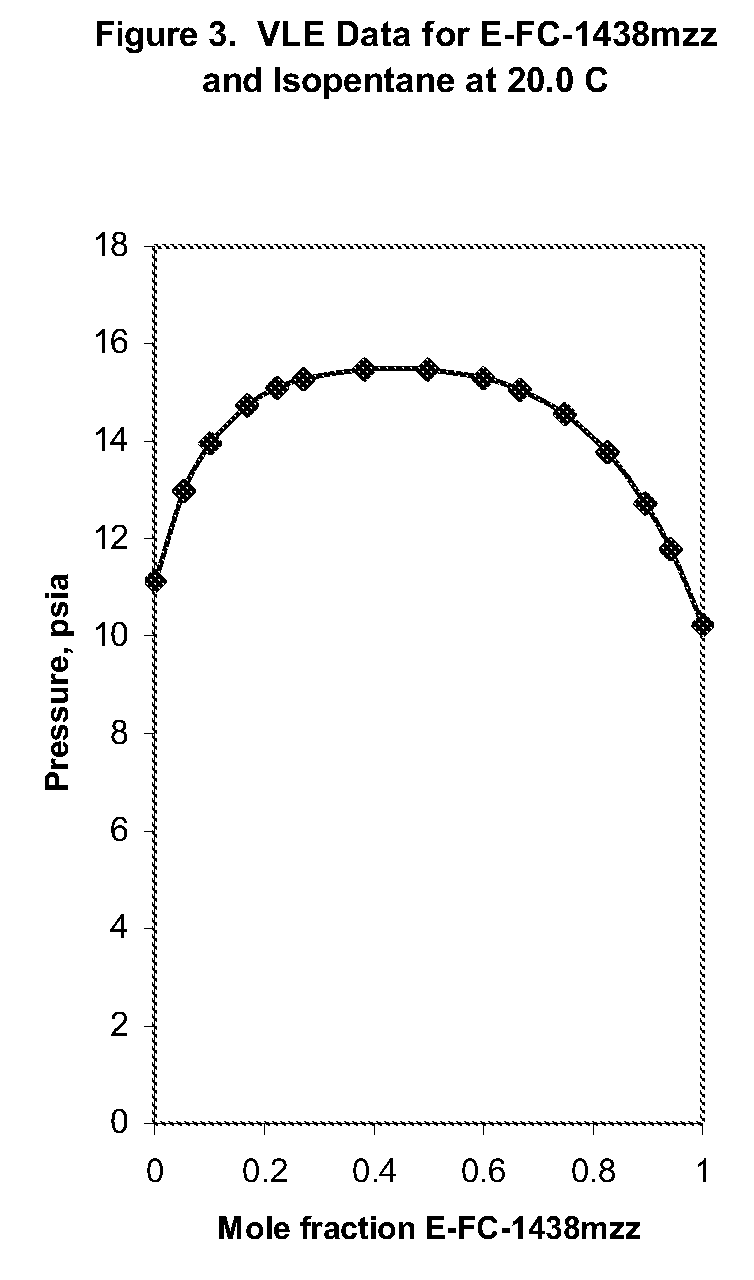

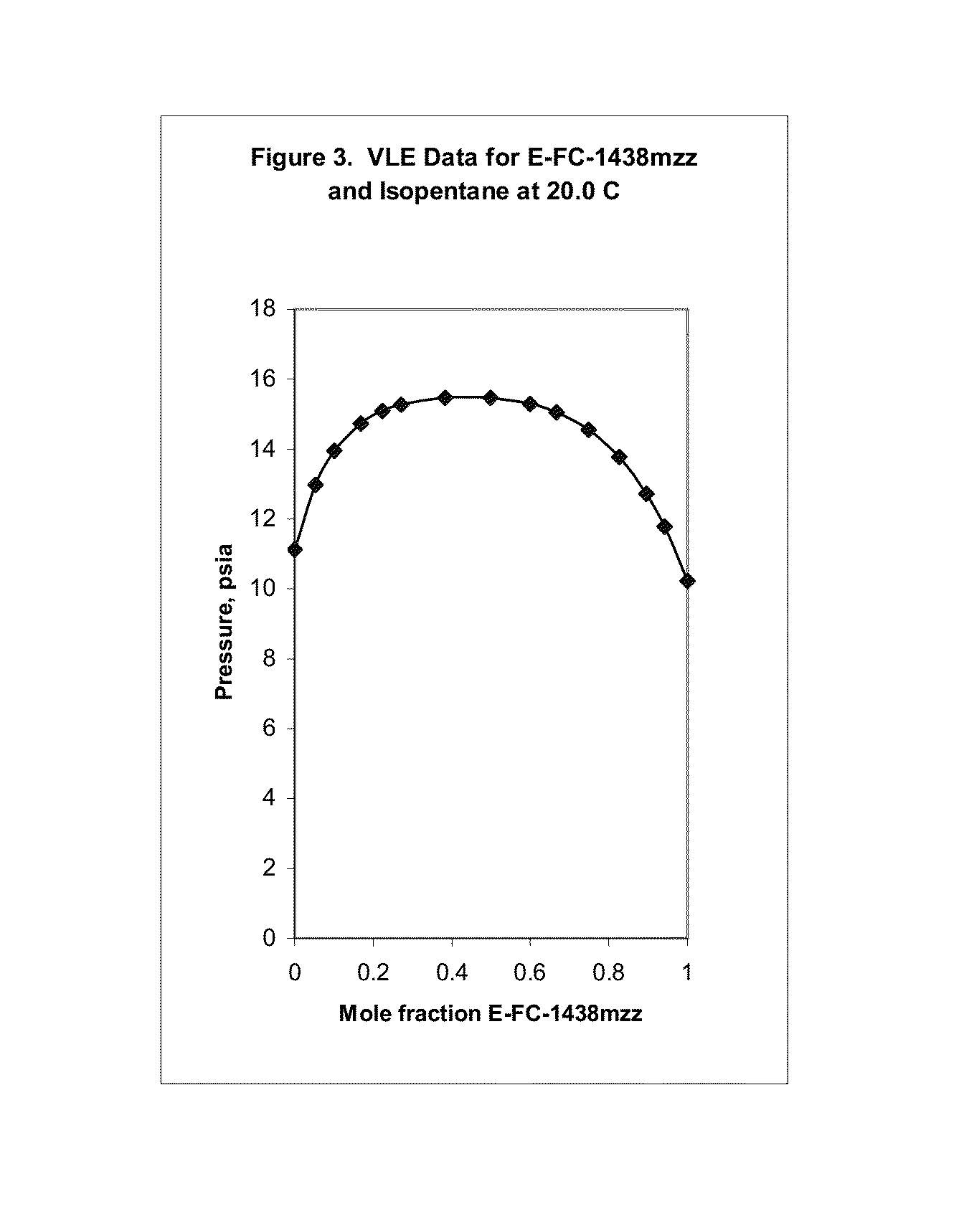

Azeotropic or azeotrope-like compositions are disclosed. The azeotropic or azeotrope-like compositions are mixtures of E-1,1,1,4,4,4-hexafluoro-2-butene with methyl formate, n-pentane, 2-methylbutane trans-1,2-dichloroethylene, 1,1,1,3,3-pentafluoropropane, n-butane or isobutane. Also disclosed is a process of preparing a thermoplastic or thermoset foam by using such azeotropic or azeotrope-like compositions as blowing agents. Also disclosed is a process of producing refrigeration by using such azeotropic or azeotrope-like compositions. Also disclosed is a process of using such azeotropic or azeotrope-like compositions as solvents. Also disclosed is a process of producing an aerosol product by using such azeotropic or azeotrope-like compositions. Also disclosed is a process of using such azeotropic or azeotrope-like compositions as heat transfer media. Also disclosed is a process of extinguishing or suppressing a fire by using such azeotropic or azeotrope-like compositions. Also disclosed is a process of using such azeotropic or azeotrope-like compositions as dielectrics.

Owner:THE CHEMOURS CO FC LLC

Azeotropic and azeotrope-like compositions of e-1,1,1,4,4,5,5,5-octafluoro-2-pentene

InactiveUS20100243943A1Organic compounds purification/separation/stabilisationOther chemical processesDielectricThermoplastic

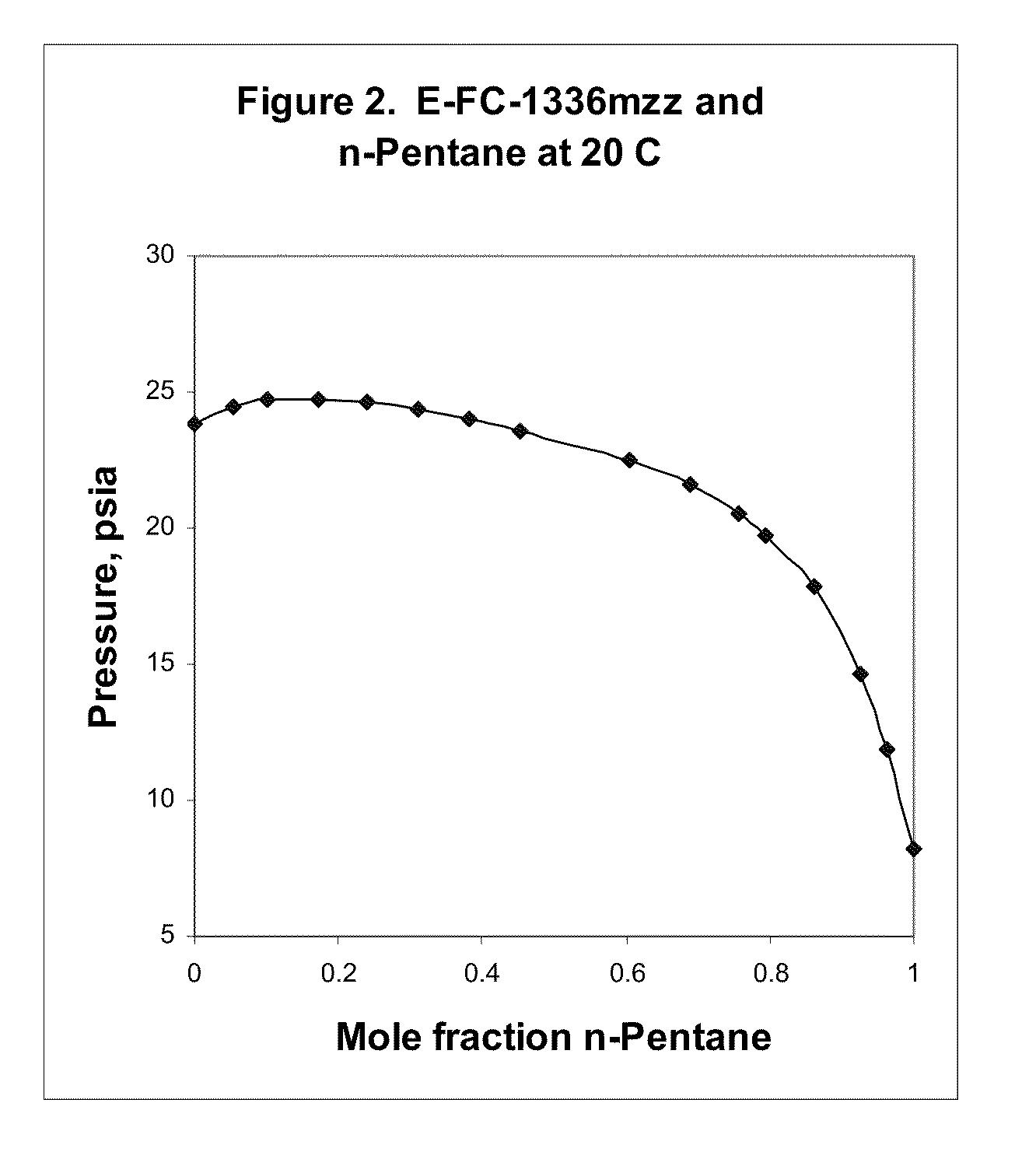

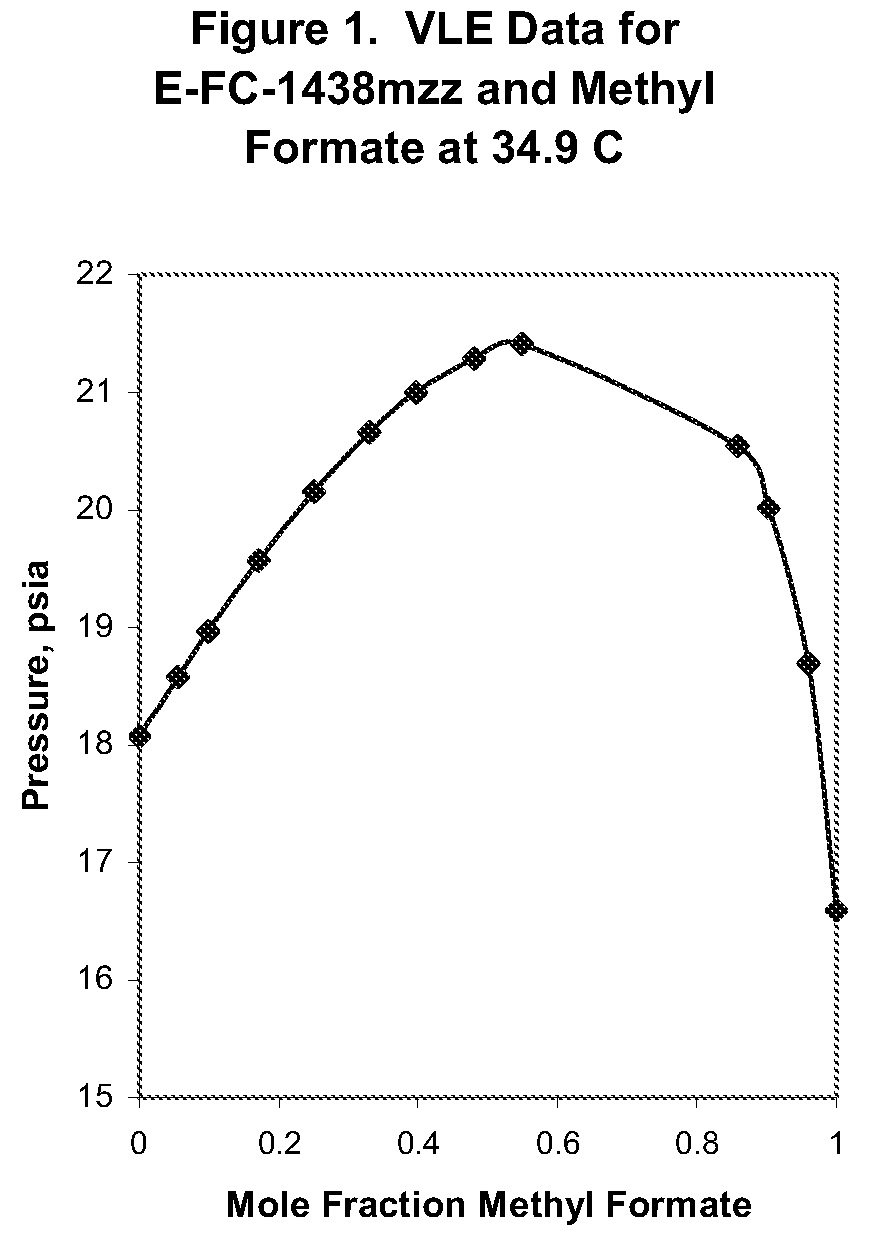

Azeotropic or azeotrope-like compositions are disclosed. The azeotropic or azeotrope-like compositions are mixtures of E-1,1,1,4,4,5,5,5-Octafluoro-2-pentene with methyl formate, n-pentane, 2-methylbutane, 1,1,1,3,3-pentafluorobutane, trans-1,2-dichloroethylene, 1,1,1,3,3-pentafluoropropane, dimethoxymethane, cyclopentane or Z-1,1,1,4,4,4-hexafluoro-2-butene. Also disclosed is a process of preparing a thermoplastic or thermoset foam by using such azeotropic or azeotrope-like compositions as blowing agents. Also disclosed is a process of producing refrigeration by using such azeotropic or azeotrope-like compositions. Also disclosed is a process of using such azeotropic or azeotrope-like compositions as solvents. Also disclosed is a process of producing an aerosol product by using such azeotropic or azeotrope-like compositions as propellants. Also disclosed is a process of using such azeotropic or azeotrope-like compositions as heat transfer media. Also disclosed is a process of extinguishing or suppressing a fire by using such azeotropic or azeotrope-like compositions. Also disclosed is a process of using such azeotropic or azeotrope-like compositions as dielectrics. Also disclosed is a process for the separation of a chemical compound from a mixture of two or more chemical compounds using such azeotropic or azeotrope-like compositions.

Owner:THE CHEMOURS CO FC LLC

Non-flammable, high-solvency compositions comprising trans-1,2-dichloroethylene, solvent, and inerting agent

InactiveUS6852684B1Easy to cleanNon flammableOrganic detergent compounding agentsOther chemical processesChlorofluorocarbonKetone

Disclosed are non-flammable, high-solvency compositions having utility as cleaning agents in the electronics and refrigeration industries, and as a medium for mold release agents. The compositions are non-flammable by Flame Extension Test ASTM D-3065 and Flash Point-Tag Closed Cup Test ASTM D-56-82, and have a Kauri Butanol value of at least about 40 by ASTM 1133-94. The compositions comprise the components: a.) trans-1,2-dichloroethylene; and b.) solvent selected from: i.) oxygen-containing solvents selected from alcohols, ketones, esters, siloxanes, and ethers; and ii.) hydrocarbon solvents represented by CtH2t+2 or CtH2t, wherein t is from 4 to 8; and c.) an inerting agent selected from: i.) hydrofluorocarbon inerting agents represented by the formula CxHyF(2x+2−y), wherein x is from 3 to 8, y is from 1 to 4, and the mole ratio of F / H in the hydrofluorocarbon inerting agent is greater than 1.6; ii.) hydrofluorocarbon ether inerting agents represented by the formula CrF2r+1OCsH2s+1, wherein r and s are independently selected from 1 to 6, and r is greater than or equal to 2s; and iii.) hydrochlorofluorocarbon inerting agents represented by the formulae C2HCl2F3, C2HClF4, and C3HCl2F5.

Owner:MICRO CARE A CONNECTICUT +1

Azeotropic and azeotrope-like compositions of methyl perfluoroheptene ethers and trans-1,2-dichloroethylene and uses thereof

ActiveUS8410039B2Detergent mixture composition preparationChemical paints/ink removersEtherDichloroethylenes

Owner:THE CHEMOURS CO FC LLC

Compositions and uses of trans-1,1,1,4,4,4-hexafluoro-2-butene

Disclosed is a mixture comprising the compound trans-1,1,1,4,4,4-hexafluoro-2-butene and at least one additional compound selected from the group consisting of HFOs, HFCs, HFEs, CFCs, CO2, olefins, organic acids, alcohols, hydrocarbons, ethers, aldehydes, ketones, and others such as methyl formate, formic acid, trans-1,2 dichloroethylene, carbon dioxide, cis-HFO-1234ze+HFO-1225yez; mixtures of these plus water; mixtures of these plus CO2; mixtures of these trans 1,2-dichloroethylene (DCE); mixtures of these plus methyl formate; mixtures with cis-HFO-1234ze+CO2; mixtures with cis-HFO-1234ze+HFO-1225yez+CO2; and mixtures with cis-HFO-1234ze+HFC-245fa. Also disclosed are methods of using and products of using the above compositions as blowing agents, solvents, heat transfer compositions, aerosol propellant compositions, fire extinguishing and suppressant compositions.

Owner:THE CHEMOURS CO FC LLC

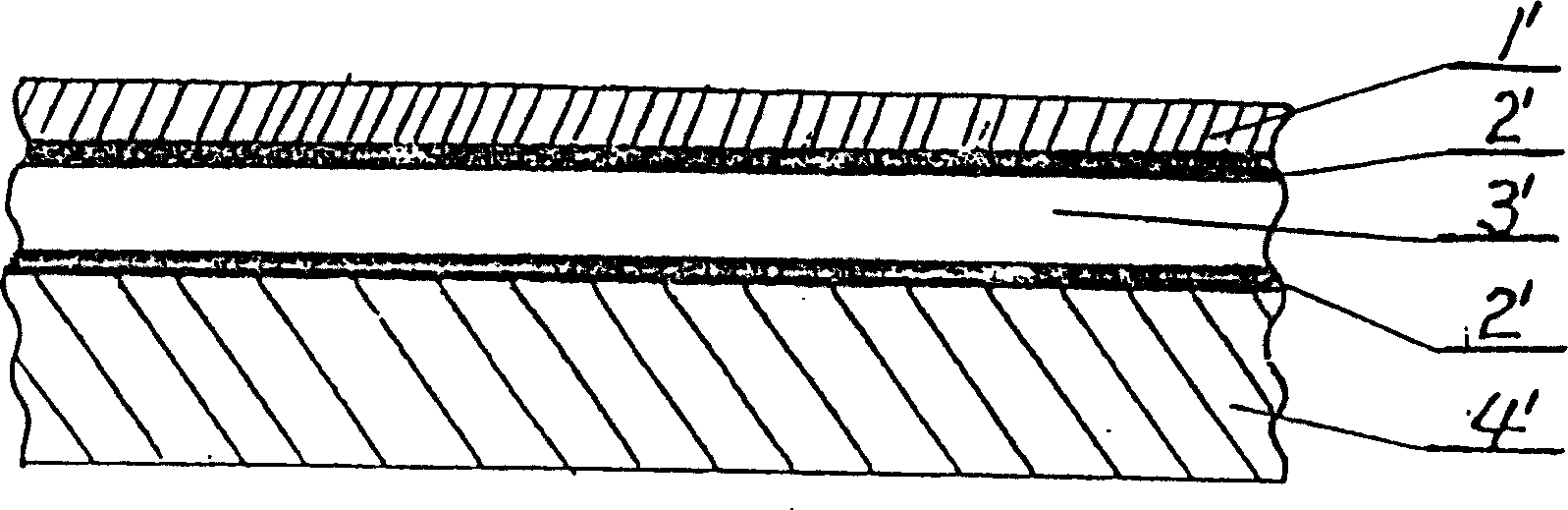

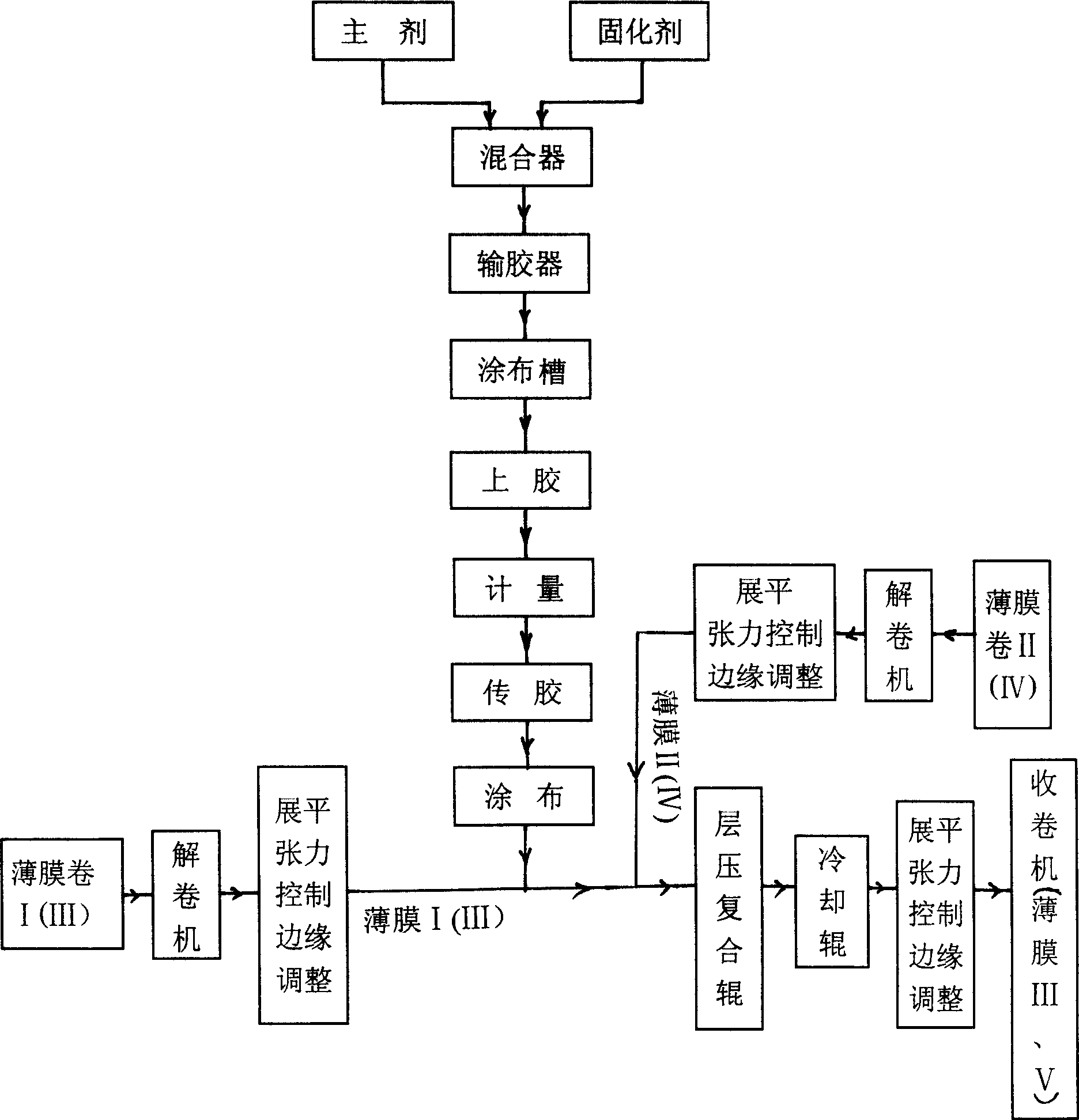

PVDC laminated composite high-temp-resistant steamed and boiled food packaging film and its preparation method

InactiveCN1535814AExtended shelf lifeEasy to buySynthetic resin layered productsSolvent freeBoiled food

The present invention relates to a PVDC laminated composite high-temp.-resistant cooked food packaging film and its preparation method. Its intermediate layer PVDC (chlorovinylidene and vinyl chloride copolymer) is respectively connected with two layers of two sides by means of binder, the described binder is a double-component polyurethane type solvent-free binder. The product can be produced by adopting said double-component polyurethane type solvent-free binder combination process and utilizing solvent-free combining machine. Said invented packaging film can meet the requirements for cooking above 121 deg.C.

Owner:郑州宝蓝包装技术有限公司

Cleaning compositions containing dichloroethylene and six carbon alkoxy substituted perfluoro compounds

InactiveUS7288511B2Without usingImprove propertiesDry-cleaning apparatus for textilesOrganic non-surface-active detergent compositionsAlkaneCyclic ether

Chemical solvating, degreasing, stripping and cleaning agents. The agents are cleaning and solvating mixtures of dichloroethylene and alkoxy-substituted perfluoro compounds that contain six carbon atoms, with optionally highly fluorinated materials to retard flammability and / or other enhancement agents that improve and enhance the properties of the composition to accomplish its desired cleaning or solvating task. These other agents are one or more of the following materials: alcohols, esters, ethers, cyclic ethers, ketones, alkanes, aromatics, amines, siloxanes terpenes, dibasic esters, glycol ethers, pyrollidones, or low- or non-ozone depleting halogenated hydrocarbons. These mixtures are useful in a variety of solvating, vapor degreasing, photoresist stripping, adhesive removal, aerosol, cold cleaning, and solvent cleaning applications including defluxing, dry-cleaning, degreasing, particle removal, metal and textile cleaning.

Owner:KYZEN CORP

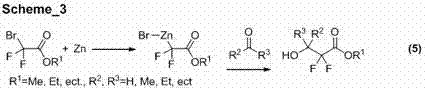

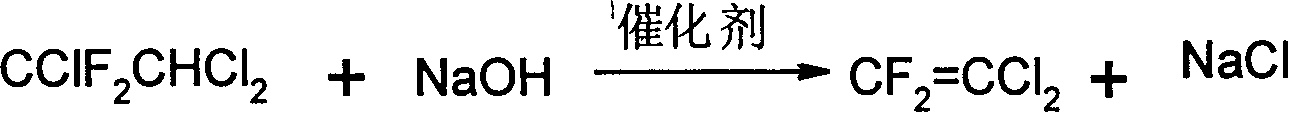

Preparation method of 2-bromo-2,2-difluoroacetyl chloride and 2-bromo-2,2-difluoro acetate and recycling method of waste difluoro trichloroethane

InactiveCN104761446AEnable recyclingIncrease added valuePreparation by hydrogen halide split-offPreparation from carboxylic acid halidesBromoethanePhenol

The invention relates to a preparation method of 2-bromo-2,2-difluoroacetyl chloride and 2-bromo-2,2-difluoro acetate and a recycling method of waste difluoro trichloroethane. The preparation method comprises the following steps: with waste difluoro trichloroethane produced in the production process of dichlorotrifluoroethane as a raw material, carrying out dehydrochlorination to obtain difluoro dichloroethylene, carrying out addition reaction on difluoro dichloroethylene and bromine to obtain difluoro dichlone dibromoethane; reacting difluoro dichlone dibromoethane with sulfur trioxide to obtain 2-bromo-2,2-difluoroacetyl chloride; and reacting 2-bromo-2,2-difluoroacetyl chloride with alcohol or phenol to obtain 2-bromo-2,2-difluoro acetate series products. According to the preparation method and the recycling method, recycling of waste difluoro trichloroethane is realized; 2-bromo-2,2-difluoroacetyl chloride and 2-bromo-2,2-difluoro acetate are prepared by a temperature oscillation method, so that the production cost is reduced; and meanwhile, the preparation method is an environment-friendly technique for producing products.

Owner:JIANGXI SUNWAY CHEM CO LTD

Method for preparing lithium iron cell protective film and solvent for cleaning said protective film

InactiveCN1588671ASolve corrosiveEasy to operateAnti-corrosive paintsCell component detailsEpoxy polyamideDiethyl ether

A prepn. method for protective film of lithium ion cell. At least one organic polymer among phenolic resin, epoxy resin, polyvinyl acetate, polyurethane, polytetrafluoroethylene, chloronorgutta, phenolic chloronorgutta, epoxy polyamide and phenolic polyvinyl acetal is added into particular solvent selected at least one from diionized water, carbinol, benzene, toluene, chloroform dichloroethylene, diethyl ether, acetone, ethyl acetate and normal ethane, they are mixed and stirred to organic solution which is coated on case of lithium ion cell, then the case is static placed to volatilize particular solvent in the organic solution in room temp. to form a layer of uniform and densify protective film on cell case. Said film can prevent corrding of electrolyte and perspiration in prodn process. The invent is also relates to a solvent used for cleaning said proctive film selected from deionized water, alcohol, acetone, oxolane and formyldimethylamine.

Owner:HENAN HUANYU GROUP

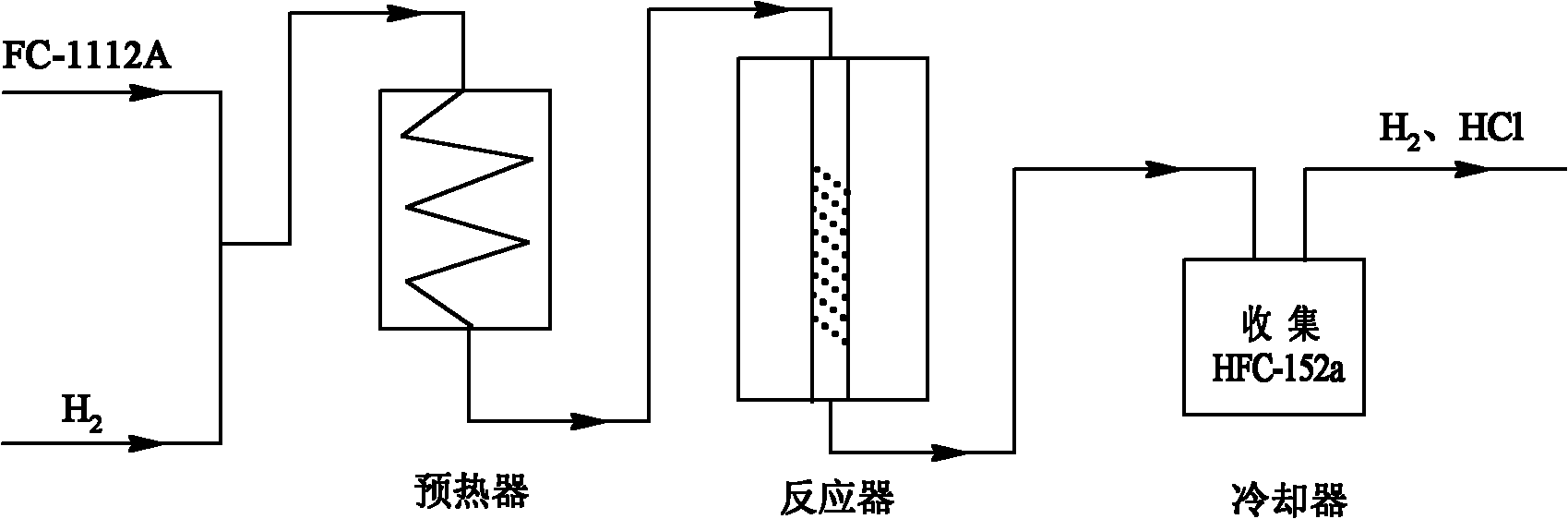

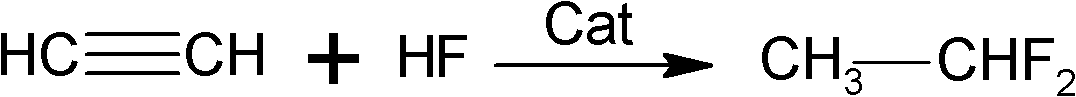

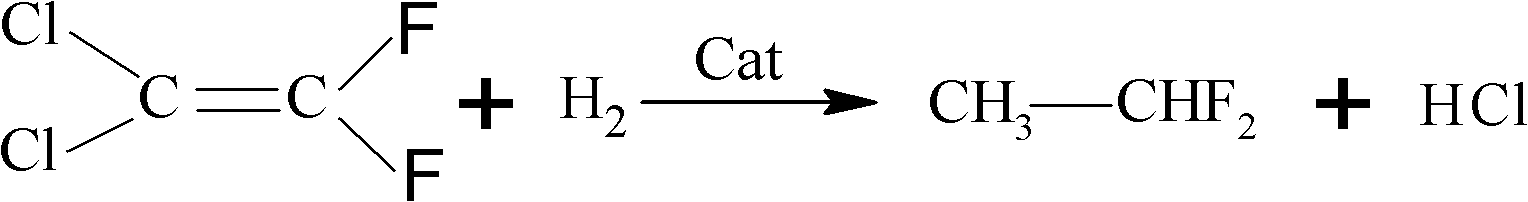

Preparation method of 1,1-difluoroethane

ActiveCN102838446ASimple post-processingMild conditionsPreparation by dehalogenationMetal/metal-oxides/metal-hydroxide catalysts1,1-DifluoroethaneHydrogen

The invention discloses a preparation method of 1,1-difluoroethane. Under the existence of a catalyst, difluoro dichloroethylene and hydrogen are subjected to a hydrodechlorination reaction, such that 1,1-difluoroethane is prepared. The catalyst is composed of a main catalyst, an auxiliary agent, and a carrier. The main catalyst is Pd, the auxiliary agent is one or more selected from La, Ce, Cu, Zn or Ni, and the caralyst is loaded on the carrier. The preparation method disclosed by the invention has the advantages of novel raw material route, mild reaction conditions, simple product post-treatment, high catalyst efficiency, and the like. A conversion rate upon a raw material FC-1112A can be higher than 90%, and a selectivity of HFC-152a can be higher than 90%.

Owner:SINOCHEM LANTIAN +1

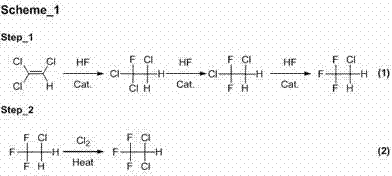

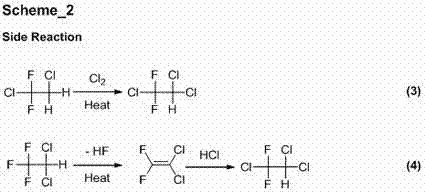

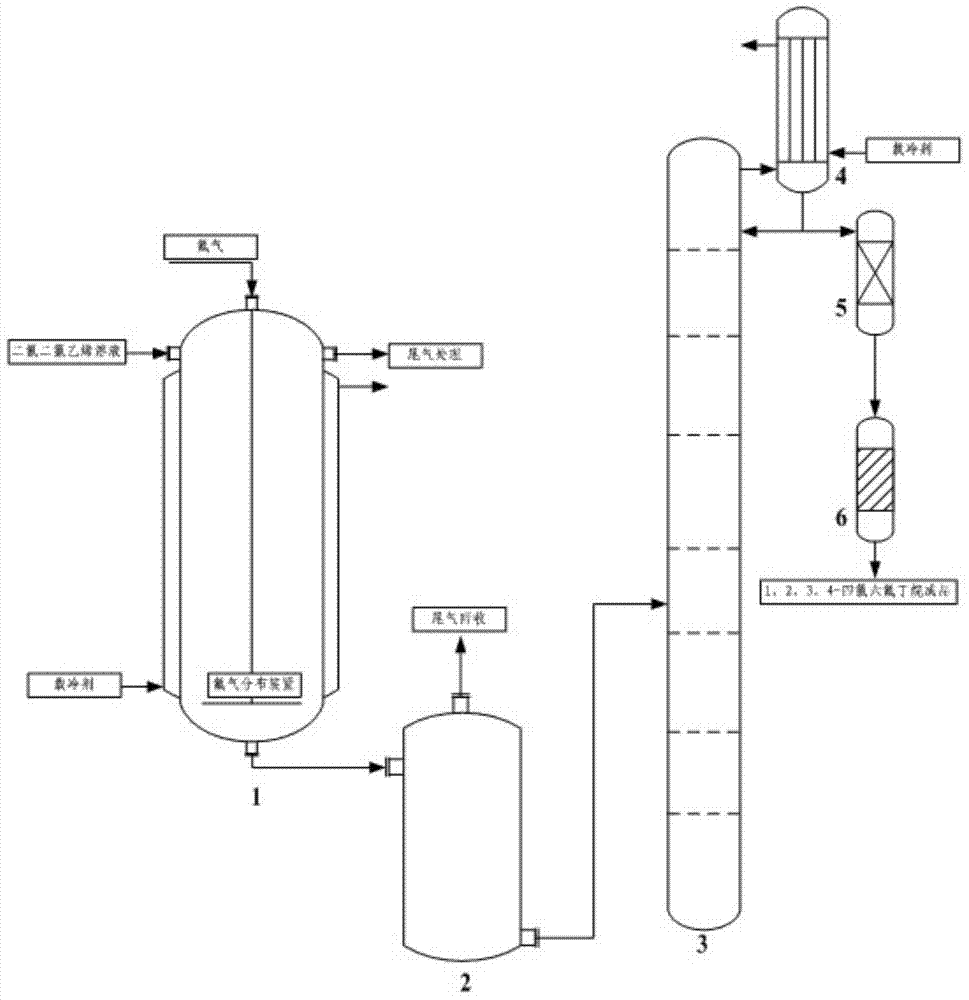

Methods for synthesizing and purifying 1, 2, 3, 4-tetrafluorohexafluorobutane

ActiveCN103664503ALow costHigh economic valueHalogenated hydrocarbon separation/purificationReaction temperatureSide reaction

The invention relates to methods for synthesizing and purifying 1, 2, 3, 4-tetrafluorohexafluorobutane. The methods comprise the steps as follows: a 1, 2-difluoro-1, 2-dichloroethylene solution and fluorine gas react in a mole ratio of (0.2-0.5): 1 at the temperature ranging from subzero 20 DEG C to subzero 100 DEG C under the contion of lower than 0.1 Mpa, and an obtained solution contains 1, 2, 3, 4-tetrafluorohexafluorobutane; and the obtained solution is distilled, rectified and dried sequentially so as to obtain highly-purified 1, 2, 3, 4-tetrafluorohexafluorobutane. According to the invention, the preparation technology of 1, 2, 3, 4-tetrafluorohexafluorobutane has a short route and only requires one-step reaction and three-step purification; preparation of 1 mol of 1, 2, 3, 4-tetrafluorohexafluorobutane only requires to consume 1 mol of theoretical fluorine gas amount, and the raw material cost is reduced; the reaction temperature is low, the side reaction is reduced, and byproducts have higher economic values; the reaction is easy to control, and the operation is simple; and the raw material conversion rate is close to 100%. The methods have higher economical efficiency, and can be industrial mass production of 1, 2, 3, 4-tetrafluorohexafluorobutane.

Owner:ZHONGHAO CHENGUANG RES INST OF CHEMICALINDUSTRY CO LTD

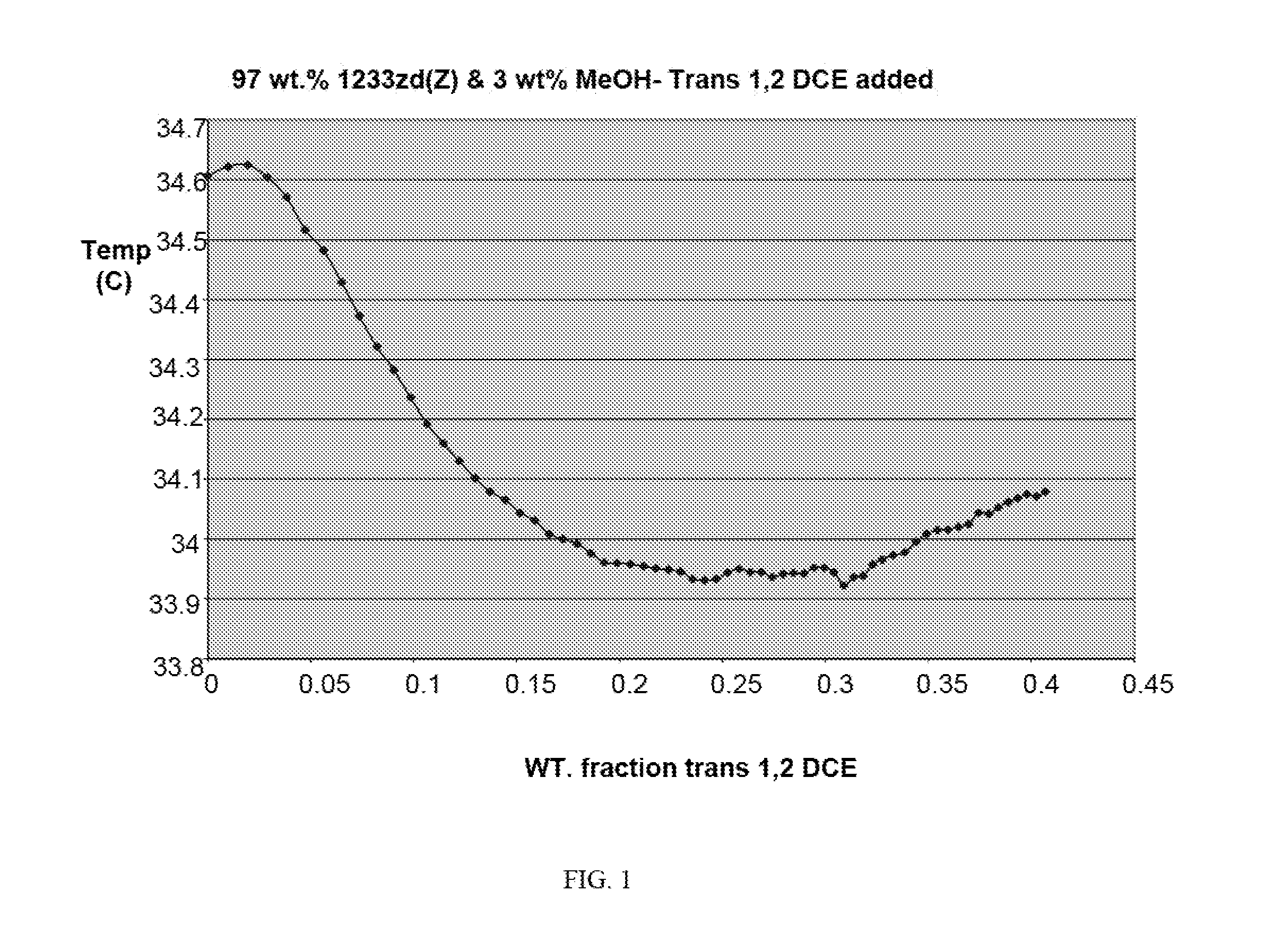

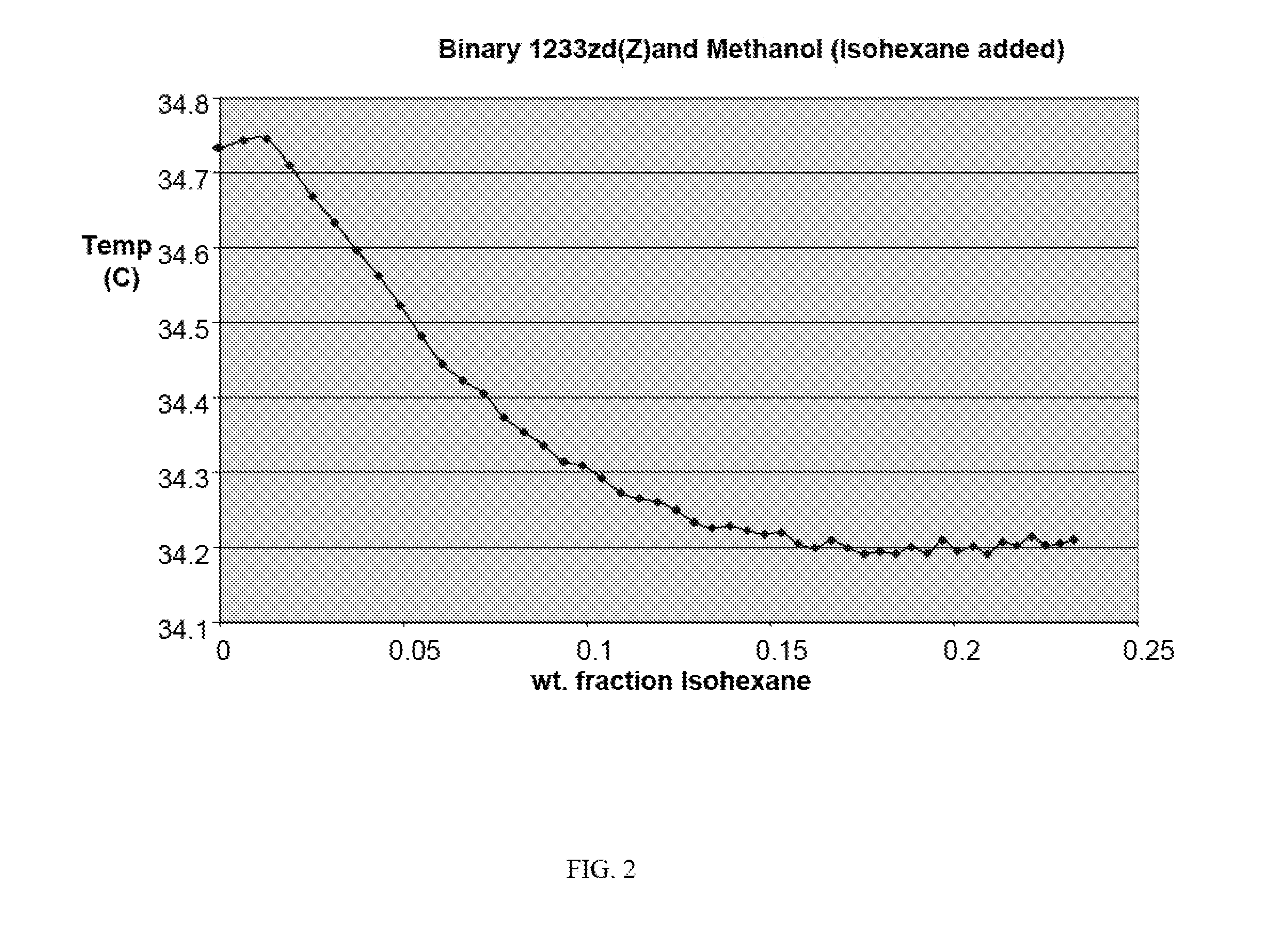

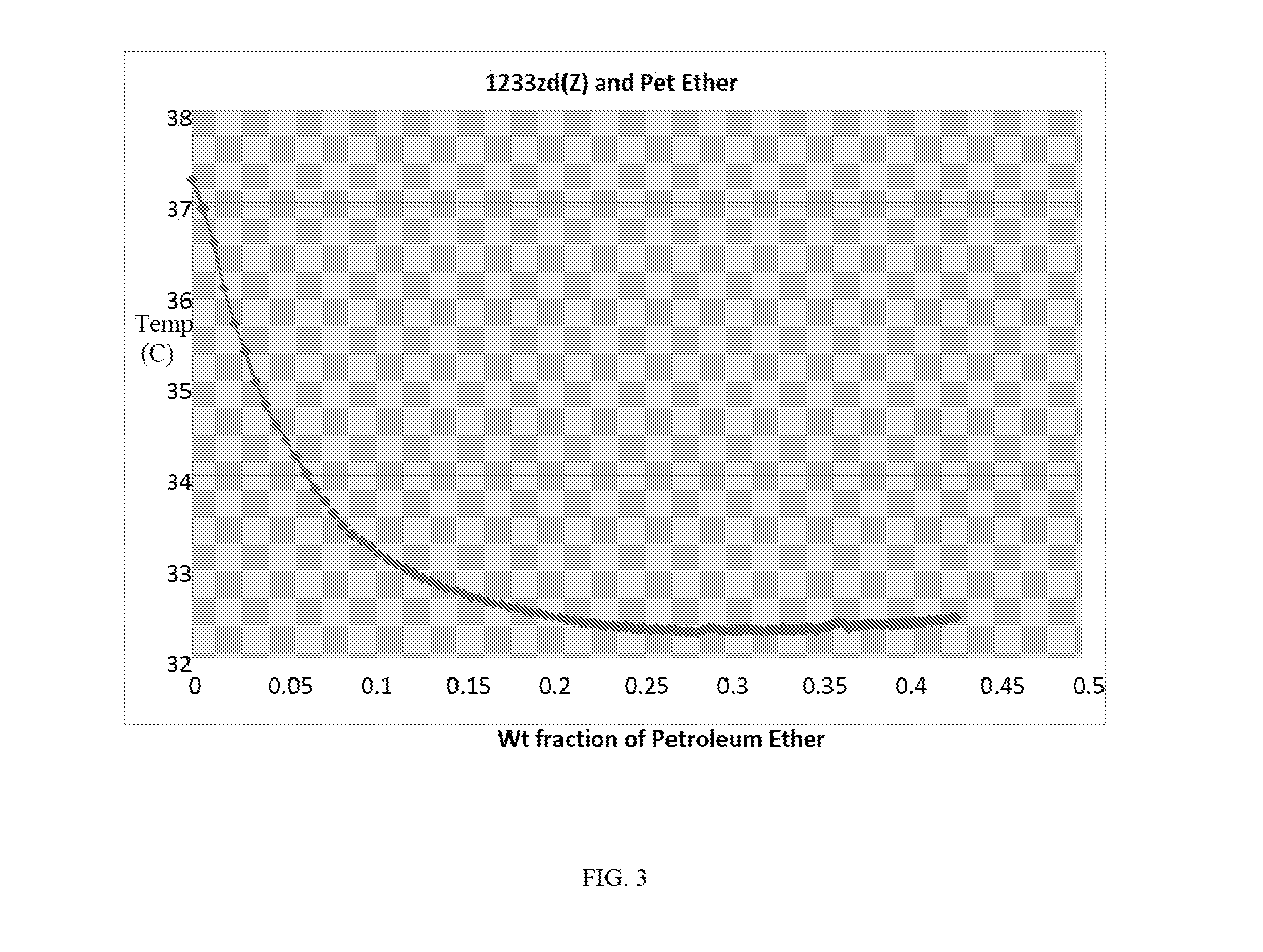

Azeotrope-like compositions comprising 1-chloro-3,3,3-trifluoropropene

InactiveUS20140206589A1Number of applicationOther chemical processesDetergent mixture composition preparationAzeotropeMethanol

The present invention relates, in part, to binary azeotropic compositions and mixtures including chlorotrifluoropropene and petroleum ether and to ternary azeotropic compositions and mixtures including chlorotrifluoropropene, methanol, and a third component selected from isohexane, trans-1,2-dichloroethylene, and petroleum ether. The present invention further relates to ternary azeotropic compositions and mixtures including chlorotrifluoropropene, cyclopentane, and a alcohol selected from methanol, ethanol, and isopropanol.

Owner:HONEYWELL INT INC

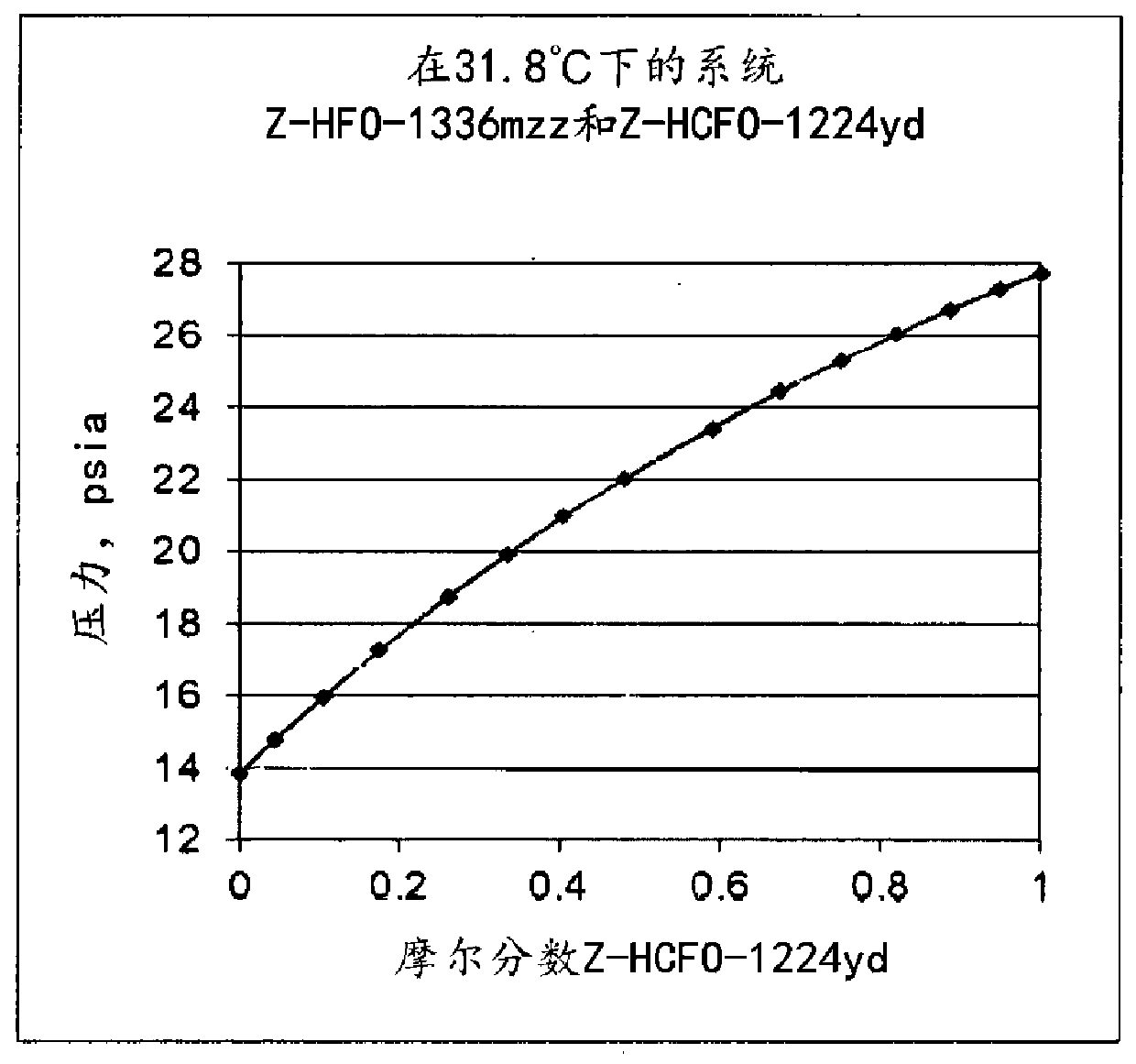

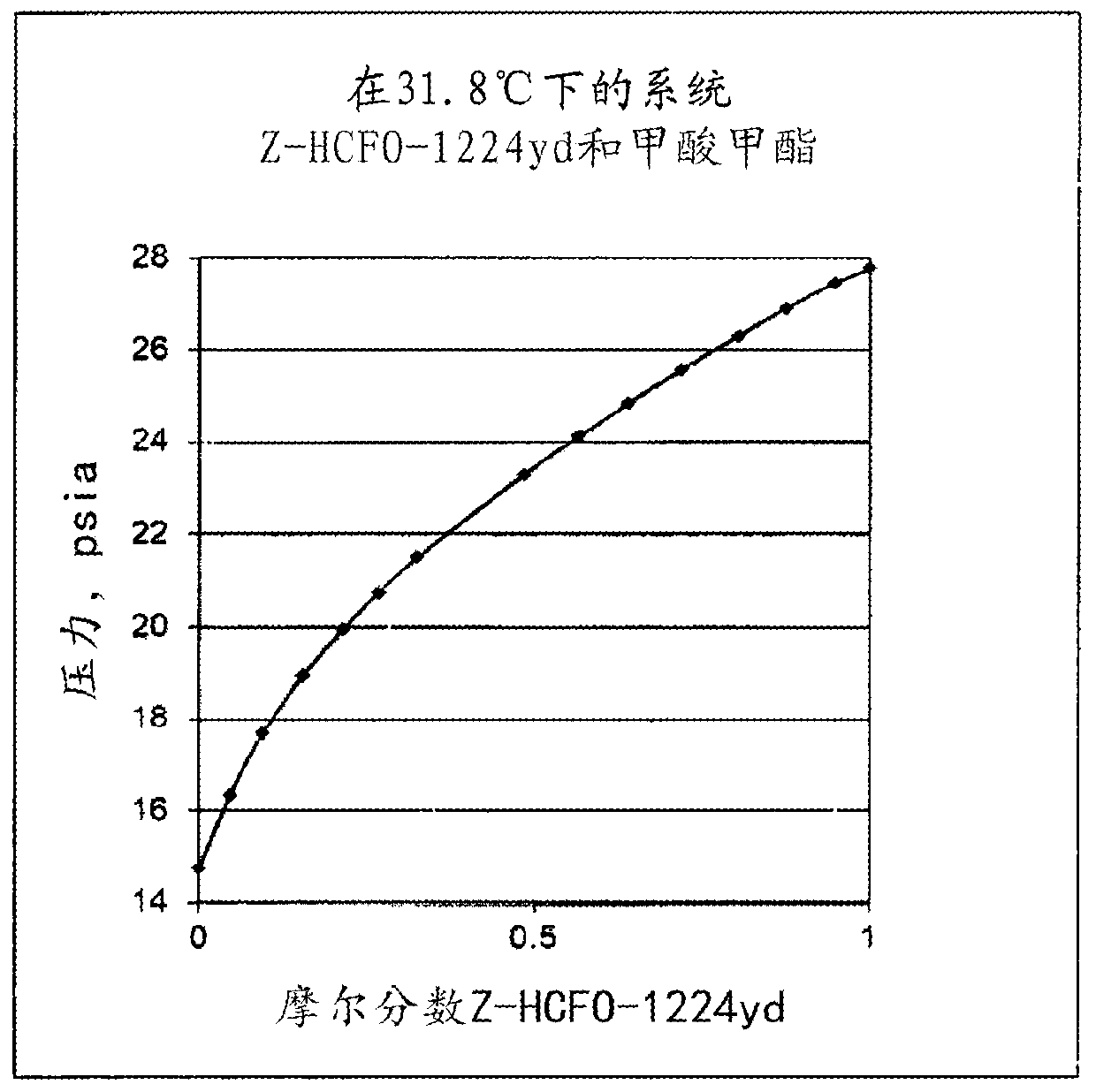

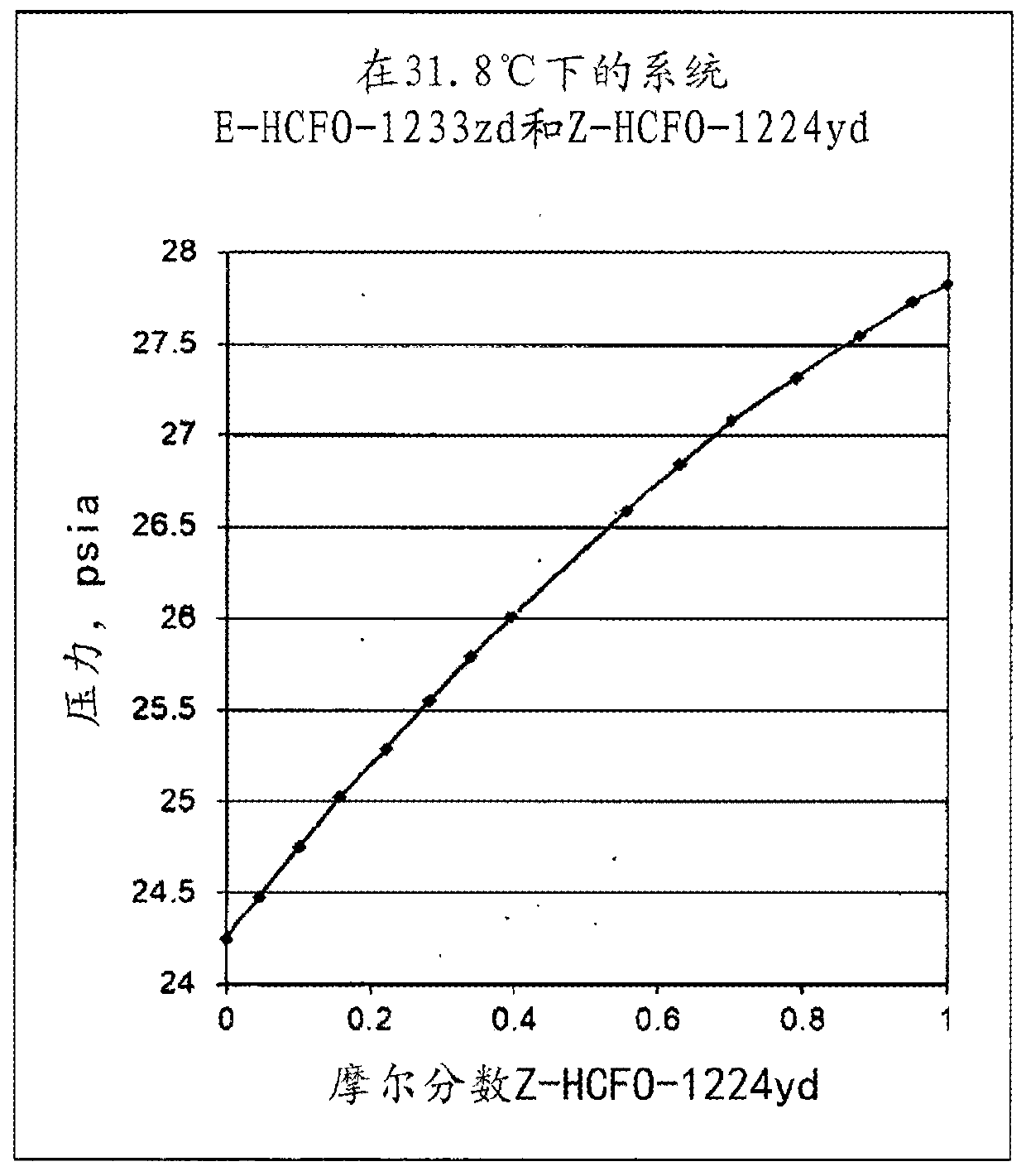

Compositions and uses of z-1-chloro-2,3,3,3-tetrafluoroprop-1-ene

PendingCN111183200AImprove thermal performanceOther chemical processesHeat-exchange elementsKetoneAzeotrope

Disclosed is a mixture comprising the compound Z-1-chloro-2,3,3,3-tetrafluoroprop-1-ene and at least one additional compound selected from the group consisting of HFOs, HFCs, HFEs, CFCs, CO2, olefins,organic acids, alcohols, hydrocarbons, ethers, aldehydes, ketones, and others such as methyl formate, formic acid, trans- 1,2 dichloroethylene, carbon dioxide, cis-HFO-1234ze+HFO-1225yez; mixtures ofthese plus water; mixtures of these plus CO2; mixtures of these trans 1,2-dichloroethylene (DCE); mixtures of these plus methyl formate; mixtures with cis-HFO-1234ze+CO2; mixtures with cis-HFO-1234ze+HFO-1225yez+CO2; mixtures with cis-HFO-1234ze+HFC-245fa; and azeotrope or azeotrope-like compositions. Also disclosed are methods of using the compositions as blowing agents, solvents, heat transfercompositions, aerosol propellant compositions, fire extinguishing and suppressant compositions.

Owner:THE CHEMOURS CO FC LLC

Aerosol cleaning composition

A nonflammable aerosol cleaning composition is formulated with trans 1,2 dichloroethylene, 1,1,1,2,2,3,4,5,5,5-decafluoropentane, 1,1,1,3,3 pentafluoropropane, HFC-134a, and carbon dioxide. The aerosol cleaning composition is formulated for heavy duty, high pressure, and high output cleaning applications for cleaning aviation parts, such as jet engines located about 10 feet away from a user.

Owner:ILLINOIS TOOL WORKS INC

Insecticide seed coating

InactiveCN1327365AEffective controlImprove mobilityBiocideDead animal preservationVinyl acetatePVA - Polyvinyl alcohol

The invention relates to an insecticidal seed coating agent, which includes one or more adhesives, an insecticide and a filler, which are selected from the group consisting of polyvinyl acetate, methylcellulose, polyvinyl alcohol, and vinylidene chloride. , polymers and copolymers of acrylics, cellulose, polyvinylpyrrolidone and polysaccharides, wherein the binder forms a matrix of pesticides and fillers, resulting in a seed coating agent that is substantially free of phytotoxicity; the seed coating agent and a method for producing seeds treated with the above-mentioned seed coating agent. Furthermore, the present invention relates to a method for controlling soil-borne pests, in particular pests of the order Coleoptera such as Chrysanthemum, comprising applying to seeds an insecticidal seed coating agent as described above.

Owner:SYNGENTA PARTICIPATIONS AG

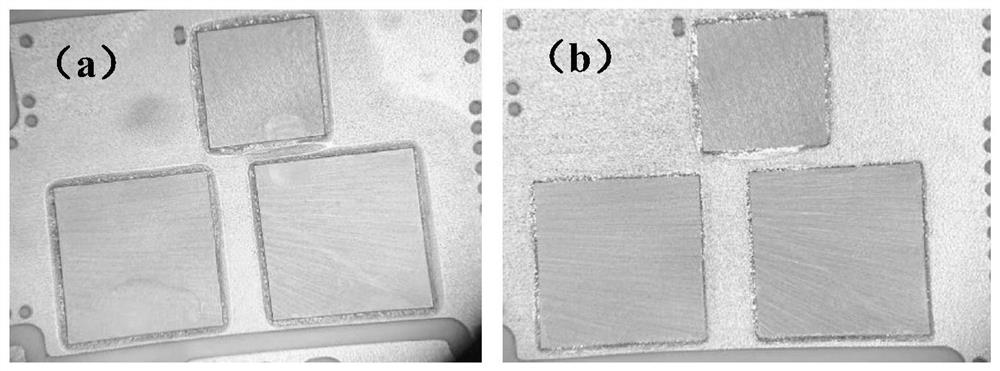

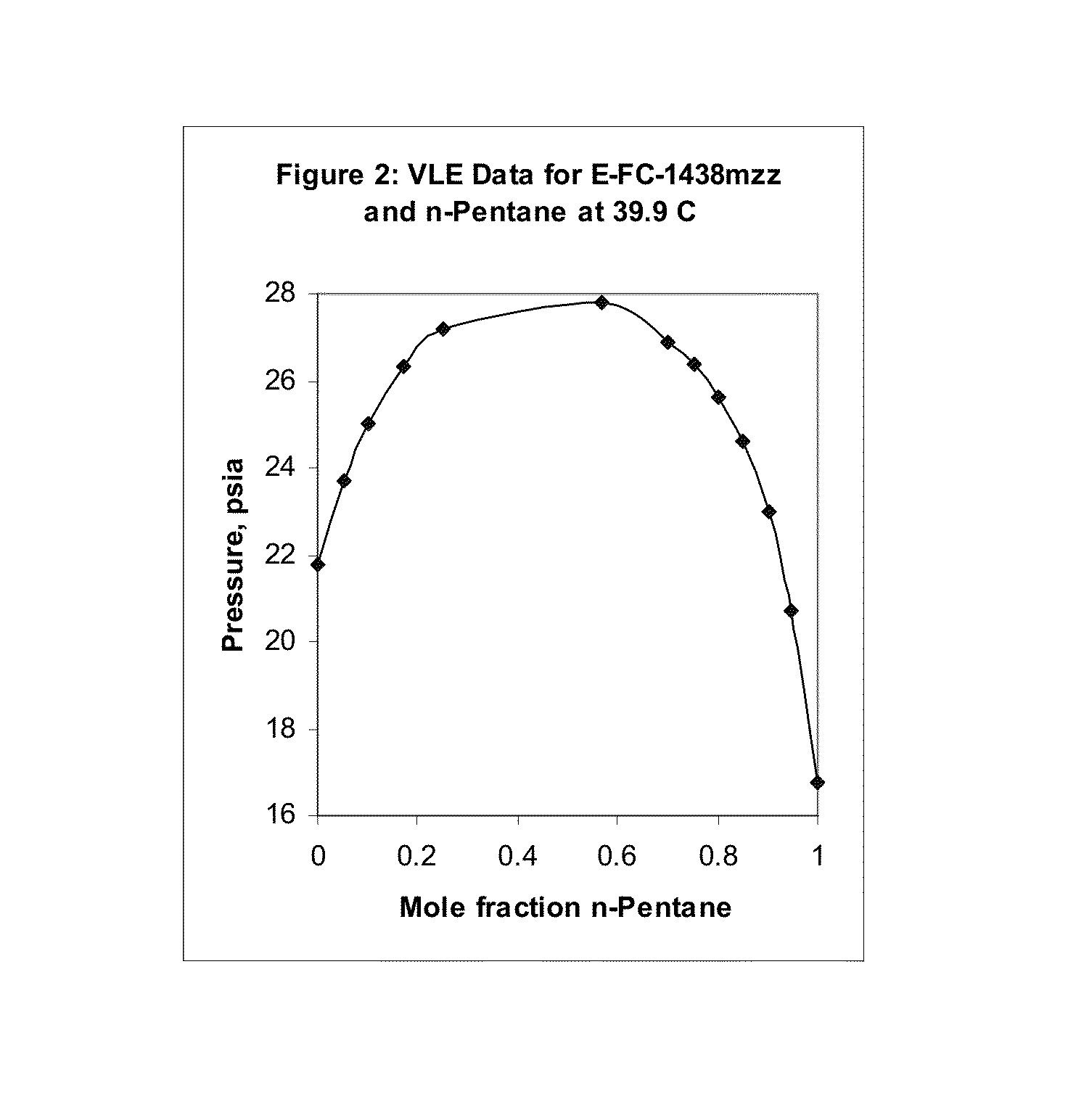

Halogenated olefin combined solvent containing 1-chloro-2, 3, 3-trifluoropropene and application thereof

The invention relates to the technical field of fluorine-containing cleaning agents, and provides a halogenated olefin combined solvent containing 1-chloro-2, 3, 3-trifluoropropene. The halogenated olefin combined solvent is prepared from the following components in parts by mass: 3 to 90 parts of 1-chloro-2, 3, 3-trifluoropropene, 5 to 95 parts of trans-1, 2-dichloroethylene; and 0.2 to 5 parts of methyl perfluoroheptene ether. According to the invention, the synergistic effect of the three substances is utilized; azeotrope or approximate azeotrope can be formed, the obtained combined solventis stable, free of flash point, low in toxicity and corrosivity, good in material compatibility, good in dissolving and removing capacity for pollutants and high in volatilization drying speed, the ODP value (ozone consumption potential value) is zero, and the GWP value (global warming potential value) is extremely low. The invention also provides an application of the halogenated olefin combinedsolvent in a cleaning agent, a diluent and an aerosol.

Owner:SHANGHAI RICHEM ENVIROTEC CO LTD

HVAC/R system contaminant removal solvent having N-propanol and flame suppresion additives, and method for flushing HVAC systems using the solvent

ActiveUS9873856B1Good acidIncrease moistureDetergent mixture composition preparationCorrosion preventionSolventComponents of crude oil

An aerosolized HVAC / R system solvent for decontaminating HVAC / R components and line sets The solvent contains 25-90 wt % propellant, and 10-75 wt % solvent mixture which is about 60-95 wt % trans-1,2, dichloroethylene, about 5-20 wt % n-propanol, and an inerting constituent providing a weight percent ratio of the inerting constituent to n-propanol of less than 1.5. The solvent is packaged in a container that is connected to the HVAC / R components or line sets to be decontaminated for supplying the solvent mixture under pressure to the HVAC / R components or line sets.

Owner:MAINSTREAM ENG

Azeotropic and azeotrope-like compositions of z-1,1,1,4,4,4-hexafluoro-2-butene, trans-1,2-dichloroethylene, and 1,1,1,3,3-pentafluorobutane

InactiveUS20130119292A1Other chemical processesLighting and heating apparatusDielectricThermoplastic

Azeotropic or azeotrope-like compositions are disclosed. The azeotropic or azeotrope-like compositions are mixtures of Z-1,1,1,4,4,4-hexafluoro-2-butene, trans-1,2-dichloroethylene and 1,1,1,3,3-pentafluorobutane. Also disclosed is a process of preparing a thermoplastic or thermoset foam by using such azeotropic or azeotrope-like compositions as blowing agents. Also disclosed is a process of producing refrigeration by using such azeotropic or azeotrope-like compositions. Also disclosed is a process of using such azeotropic or azeotrope-like compositions as solvents. Also disclosed is a process of producing an aerosol product by using such azeotropic or azeotrope-like compositions. Also disclosed is a process of using such azeotropic or azeotrope-like compositions as heat transfer media. Also disclosed is a process of extinguishing or suppressing afire by using such azeotropic or azeotrope-like compositions. Also disclosed is a process of using such azeotropic or azeotrope-like compositions as dielectrics.

Owner:THE CHEMOURS CO FC LLC

Azeotrope-like compositions of 1,1,3,3-pentafluorobutane

InactiveCN1847357AOrganic chemistryOrganic non-surface-active detergent compositionsDichloroethylenesAzeotrope

Disclosed are binary azeotrope-like compositions consisting essentially of 1,1,1,3,3-pentafluorobutane (HFC-365mfc) and 1,1,1,2,3,4,4,5,5,5-decafluoropentane (HFC-43-10mee) or nonafluoromethoxybutane. The present invention further includes ternary or quaternary azeotrope-like compositions consisting essentially of 1,1,1,3,3-pentafluorobutane and 1,1,1,2,3,4,4,5,5-decafluoropentane or nonafluoromethoxybutane, and additionally trans-1,2-dichloroethylene, n-propyl bromide, acetone, methanol, ethanol or isopropanol.

Owner:THE CHEMOURS CO FC LLC

Azeotropic and azeotrope-like compositions of z-1,1,1,4,4,4-hexafluoro-2-butene, trans-1,2-dichloroethylene, and a third component

Azeotropic or azeotrope-like compositions are disclosed. The azeotropic or azeotrope-like compositions are mixtures of Z-1,1,1,4,4,4-hexafluoro-2-butene, trans-1,2-dichloroethylene and a third component. Also disclosed are compositions where the third component is cyclopentane, methanol, dimethyoxymethane, methyl formate or perfluoro ethyl isopropyl ketone. Also disclosed is a process of preparing a thermoplastic or thermoset foam by using such azeotropic or azeotrope-like compositions as blowing agents. Also disclosed is a process of producing refrigeration by using such azeotropic or azeotrope-like compositions. Also disclosed is a process of using such azeotropic or azeotrope-like compositions as solvents. Also disclosed is a process of producing an aerosol product by using such azeotropic or azeotrope-like compositions. Also disclosed is a process of using such azeotropic or azeotrope-like compositions as heat transfer media. Also disclosed is a process of extinguishing or suppressing a fire by using such azeotropic or azeotrope-like compositions. Also disclosed is a process of using such azeotropic or azeotrope-like compositions as dielectrics.

Owner:THE CHEMOURS CO FC LLC

Azeotropic and azeotrope-like compositions of E-1,1,1,4,4,5,5,5-octafluoro-2-pentene

InactiveUS8632703B2Organic compounds purification/separation/stabilisationOther chemical processesDielectric2-methylbutane

Azeotropic or azeotrope-like compositions are disclosed. The azeotropic or azeotrope-like compositions are mixtures of E-1,1,1,4,4,5,5,5-Octafluoro-2-pentene with methyl formate, n-pentane, 2-methylbutane, 1,1,1,3,3-pentafluorobutane, trans-1,2-dichloroethylene, 1,1,1,3,3-pentafluoropropane, dimethoxymethane, cyclopentane or Z-1,1,1,4,4,4-hexafluoro-2-butene. Also disclosed is a process of preparing a thermoplastic or thermoset foam by using such azeotropic or azeotrope-like compositions as blowing agents. Also disclosed is a process of producing refrigeration by using such azeotropic or azeotrope-like compositions. Also disclosed is a process of using such azeotropic or azeotrope-like compositions as solvents. Also disclosed is a process of producing an aerosol product by using such azeotropic or azeotrope-like compositions as propellants. Also disclosed is a process of using such azeotropic or azeotrope-like compositions as heat transfer media. Also disclosed is a process of extinguishing or suppressing a fire by using such azeotropic or azeotrope-like compositions. Also disclosed is a process of using such azeotropic or azeotrope-like compositions as dielectrics. Also disclosed is a process for the separation of a chemical compound from a mixture of two or more chemical compounds using such azeotropic or azeotrope-like compositions.

Owner:THE CHEMOURS CO FC LLC

Azeotropic compositions comprising fluorinated olefins for cleaning applications

The present invention relates to azeotropic or azeotrope-like compositions comprising a fluorinated olefin having the formula E- or Z-C3F7CH═CHC3F7, and at least one alcohol, halocarbon, hydrofluorocarbon, fluoroether, or alkanes and combinations thereof. In one embodiment, the one compound selected from the group consisting of alcohols, halocarbons, fluoroalkyl ethers, hydrofluorocarbons, alkanes is either methanol, ethanol, iso-propanol, n-propanol, trans-1,2-dichloroethylene, cis-1,2-dichloroethylene, n-propyl bromide, C4F9OCH3, C4F9OC2H5, HFC-43-10mee, HFC-365mfc, heptane, or combinations thereof. In another embodiment, these compositions are useful in cleaning applications as a degreasing agent or defluxing agent for removing oils and / or other residues from a surface.

Owner:EI DU PONT DE NEMOURS & CO

Electrothermal fly fragrant liquid

The invention relates to an electrothermal fly fragrant liquid which belongs to the field of fine chemical industry. The electrothermal fly fragrant liquid uses 2, 3, 5, 6-tetrafluoro-4-methoxy methyl benzyl (1R, 3S)-3-(2, 2 - dichloro vinyl)-2, 2-dimethyl cyclopropane carboxylic ester (Product Name: meperfluthrin) as an active ingredient with the content of 0.3%-6%, uses 0.05%-6.0% of di-tert-butylphenol as a stabilizer, a proper amount of a solvent accosting for about 60% to 97% of the total, a spice accosting for about 0.3% to 2%of the total is supplemented, an ancillary use device is matched for use, and the electrothermal fly fragrant liquid is stable in volatilization, smokeless, efficient and controllable.

Owner:成都彩虹电器(集团)股份有限公司

Azeotropic composition containing 1,1,1,3,3,3-hexafluoro-2-methoxypropane

ActiveUS20200024553A1Organic non-surface-active detergent compositionsNon-surface-active detergent solventsAlcohol ethylPhysical chemistry

An azeotropic composition a formulated with 1,1,1,3,3,3,-hexafluoro-2-methoxypropane and a second component selected from the group consisting of isopropyl alcohol, ethanol, methanol, and trans-1,2-dichloroethylene. The azeotropic composition exhibits a substantially constant boiling point at a constant pressure and is useful for various cleaning and degreasing applications.

Owner:ILLINOIS TOOL WORKS INC

Preparation method for 2,2-dichloro-1,2-dibrom-1,1-difluoroethane

The invention relates to a preparation method for 2,2-dichloro-1,2-dibrom-1,1-difluoroethane from 1,1-difluorine-1,2,2-trichloroethane at the presence of its 0.5-2.0% quaternary ammonium salt or quaternary phosphonium salt phase transition catalyst, through hydrogen chloride removal under alkaline condition at 0-80 deg. C to prepare 1,1-difluorine-2,2-dichloroethylene, charging 1.0-1.5 mol weight of bromine for reaction at 0-50 deg. C.

Owner:ZHEJIANG LANTIAN ENVIRONMENTAL PROTECTION HI TECH

Compositions of methyl perfluoroheptene ethers, 1,1,1,2,2,3,4,5,5,5-decafluoropentane and trans-1,2-dichloroethylene and uses thereof

Owner:THE CHEMOURS CO FC LLC

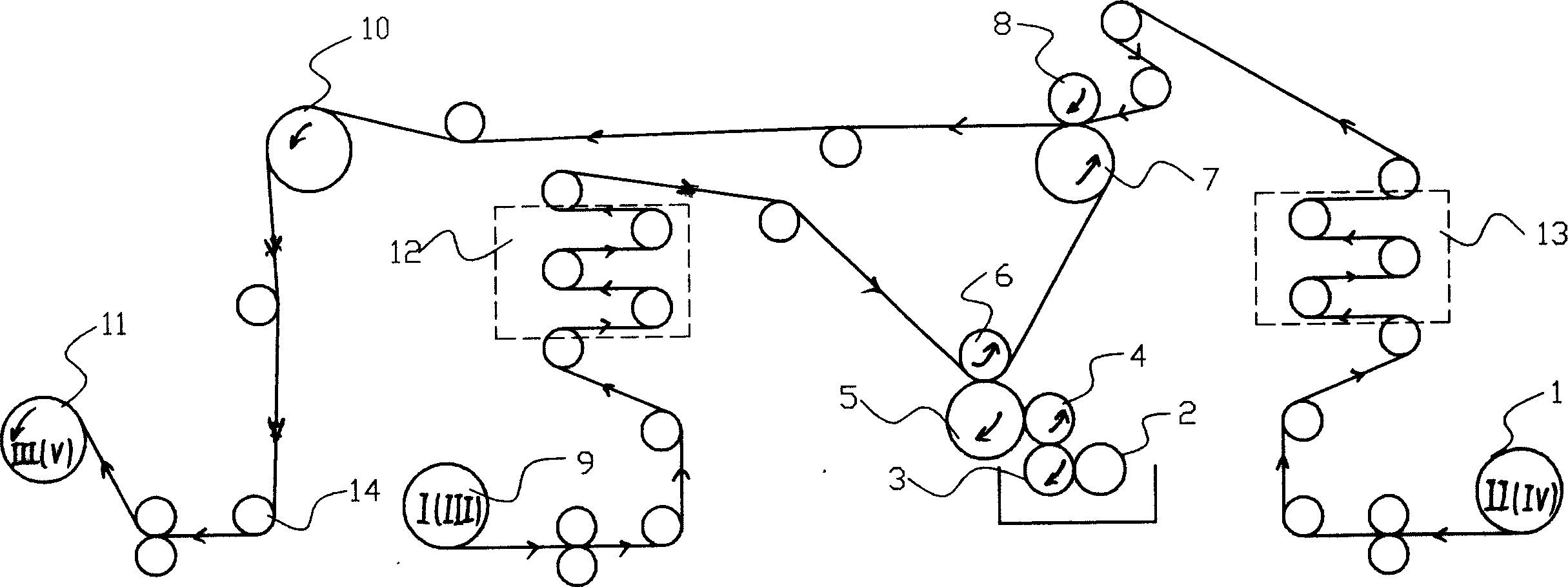

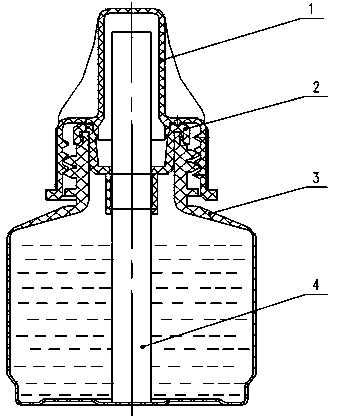

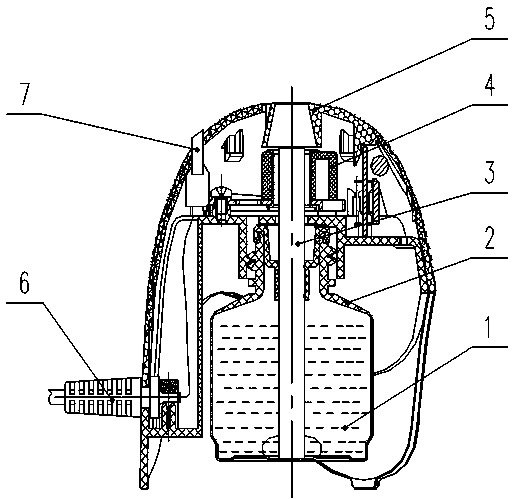

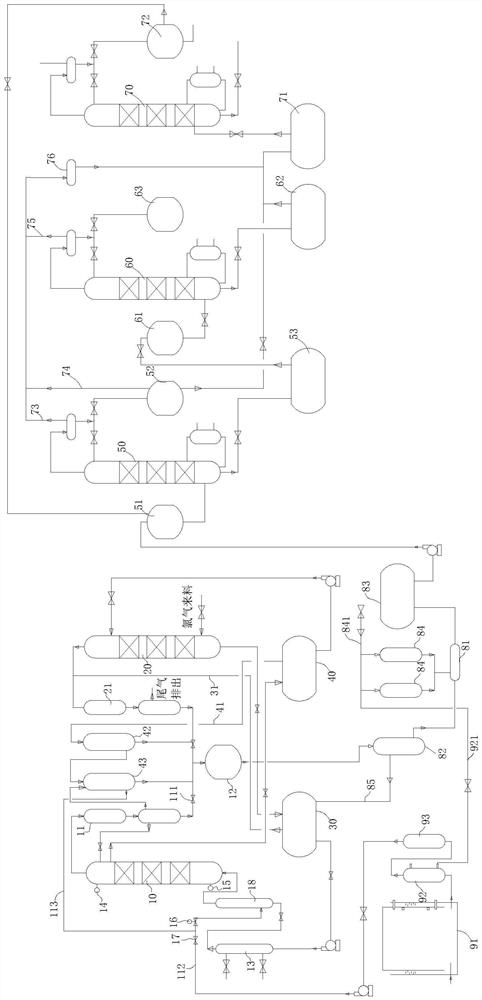

Acetylene purification interlocking control type trans-1,2-dichloroethylene preparation system

ActiveCN112961026ARealize recyclingSimple structurePreparation by halogen halide additionDichloroethylenesProcess engineering

A provided acetylene purification interlocking control type trans-1,2-dichloroethylene preparation system comprises a synthesis tower, a regeneration tower, a mother liquor storage tank, a regeneration storage tank and a neutralization device, a tower bottom gas phase inlet of the synthesis tower is used for introducing acetylene gas, a tower bottom liquid phase inlet is connected with an outlet of the mother liquor storage tank, a tower top gas phase outlet of the synthesis tower is connected with a condenser for synthesis, a tower bottom gas phase inlet of the regeneration tower is used for introducing chlorine gas, and a tower top liquid phase inelt of the regeneration tower is connected with the regeneration storage tank. The neutralization device comprises a mixer, an oil-water separator, a neutralization liquid storage tank and an alkali liquor tank, the oil-water separator is connected with an outlet of a crude product tank, an oil phase outlet of the oil-water separator is connected with an inlet of the mixer, an outlet of the mixer is connected with the neutralization liquid storage tank, and a gas treatment device is further arranged at the front end of an acetylene gas feeding pipeline. According to the scheme, the cleanliness degree of gas entering the synthesis tower meets the process requirement, and meanwhile new chemical substances cannot be introduced.

Owner:宁夏普瑞化工有限公司

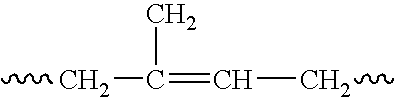

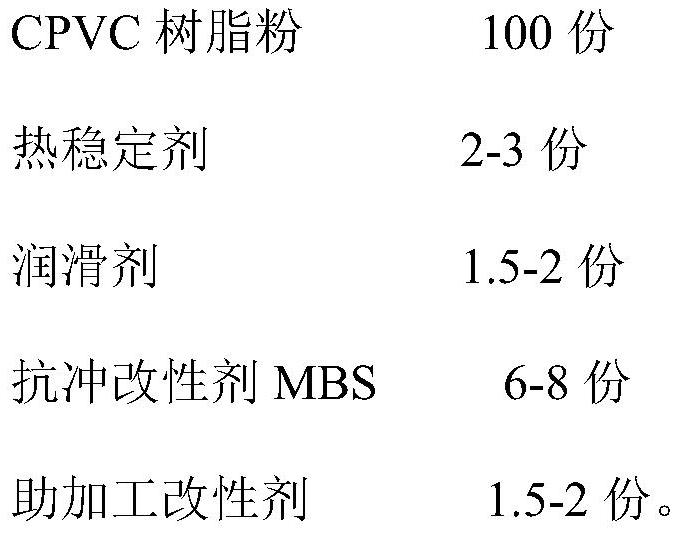

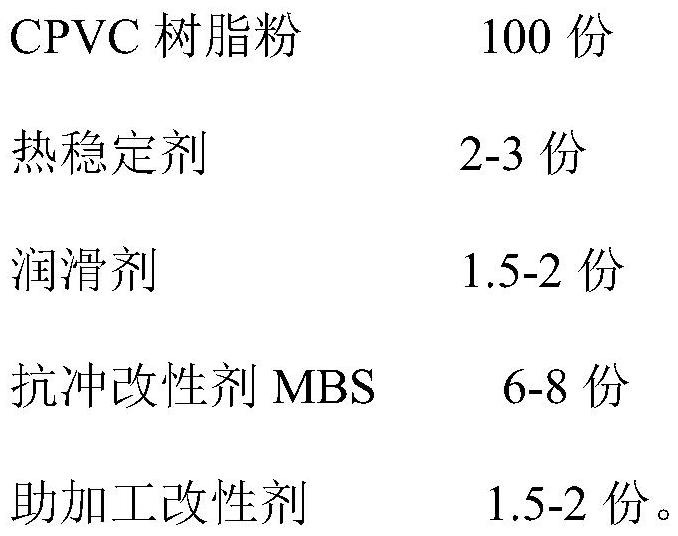

CPVC fire-fighting pipe and preparation method thereof

ActiveCN113736197AImprove performanceGood compatibilityGeneral water supply conservationAcrylate esterDichloroethylenes

The invention relates to the technical field of high polymer materials, in particular to a CPVC fire-fighting pipe and a preparation method thereof. The addition of an acrylic ester processing aid ACR in a CPVC resin formula system can lead to high torque of CPVC in the processing process and also lead to reduction of the vicat softening point of the CPVC fire-fighting pipe. In order to solve the problems, the CPVC fire-fighting pipe provided by the invention contains a self-made processing-aiding modifier, the processing-aiding modifier is obtained by copolymerizing vinyl chloride, vinylidene chloride and vinyl versatate as raw materials, and the chain structure of vinyl chloride and vinylidene chloride in the molecular structure of the processing-aiding modifier has good compatibility with CPVC, and the comprehensive performance of the CPVC fire-fighting pipe can be improved.

Owner:WUXI HONGHUI NEW MATERIALS TECH

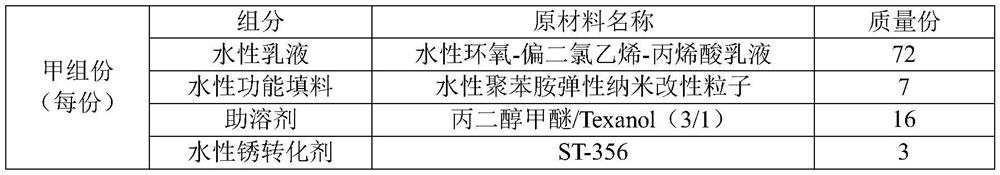

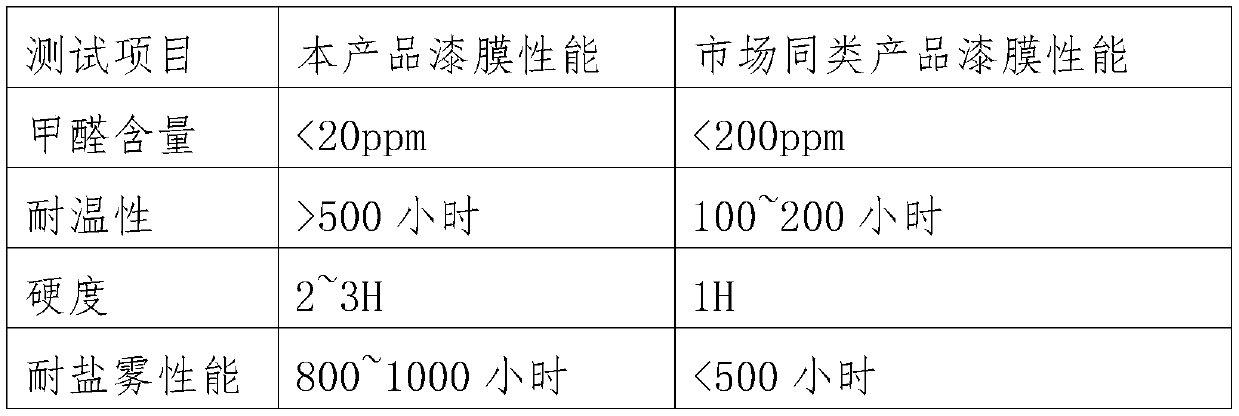

Water-based rust conversion anticorrosion coating for steel structure and preparation method thereof

ActiveCN111662603BImprove corrosion resistanceImprove air tightnessConjugated diene hydrocarbon coatingsAnti-corrosive paintsPolymer scienceEmulsion

Owner:洛阳双瑞防腐工程技术有限公司

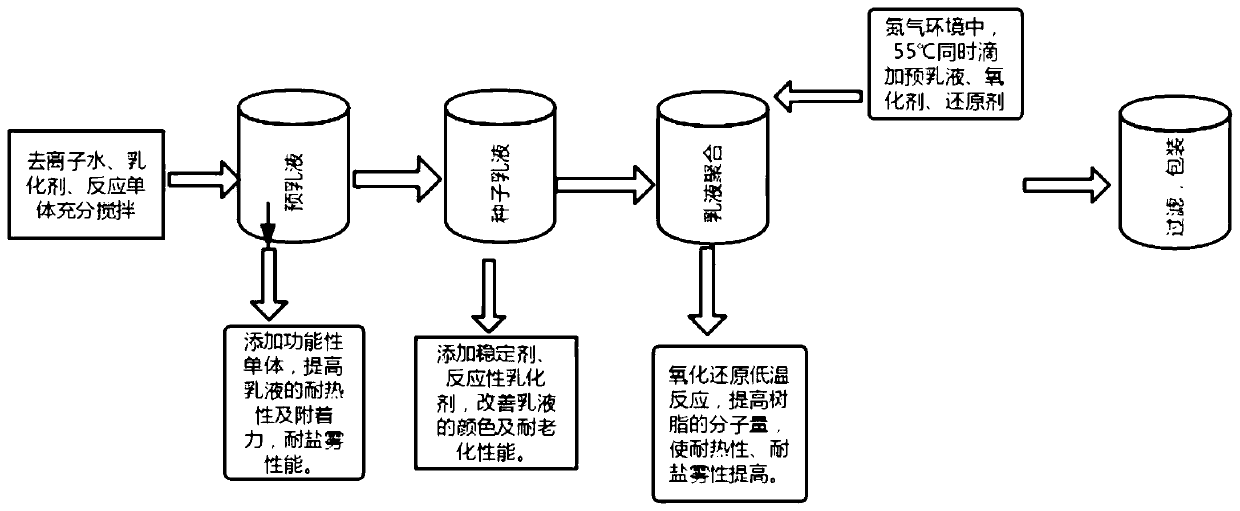

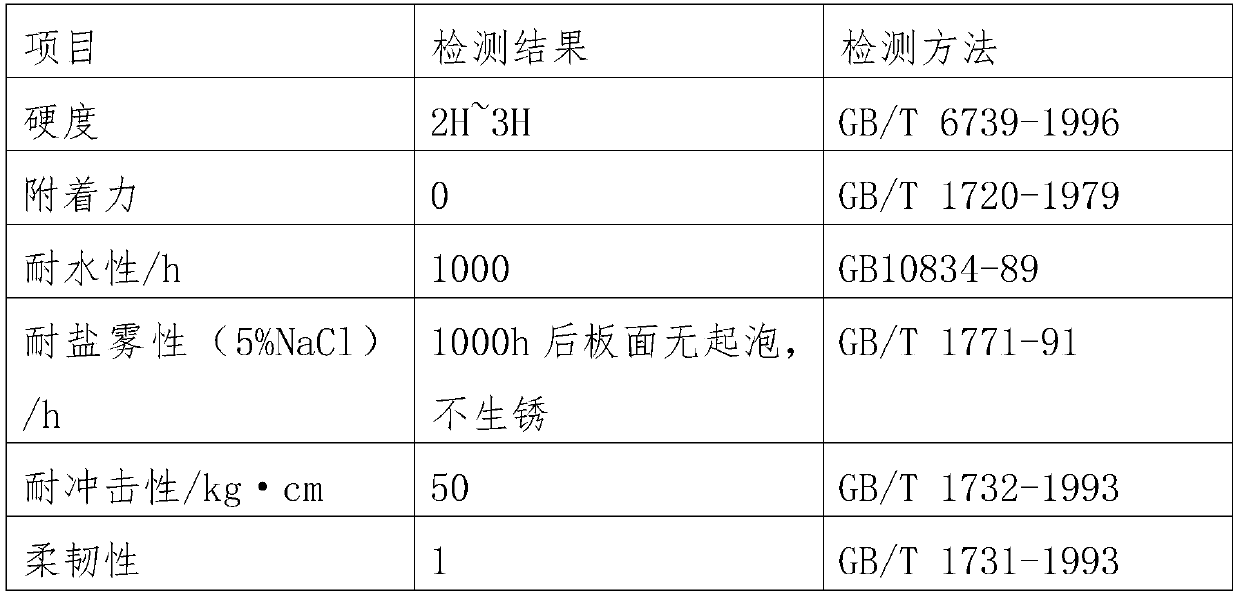

Dichloroethylene-acrylate copolymer emulsion and preparation method thereof

The invention relates to a dichloroethylene-acrylate copolymer emulsion and a preparation method thereof. The dichloroethylene-acrylate copolymer emulsion comprises 30-35% of dichloroethylene, 5-10% of an A-type reaction monomer, 0.5-2% of a B-type reaction monomer, 0.5-1% of a C-type reaction monomer, 0.001-0.01% of a reaction stabilizer, 0.5-1% of a reactive anionic emulsifier, 0.5-1% of a nonionic emulsifier, 0.00002% of an accelerant, 45-55% of deionized water and 0.05-0.3% of a redox initiator. Through the processes of pre-emulsion preparation, seed emulsion preparation, emulsion drop-by-drop-adding polymerization and curing, the defects of a conventional emulsifier are overcome, and the water resistance, the adhesive force and the salt spray resistance of a paint film are improved; and the environment-friendly emulsion with high molecular weight, paint film yellowing resistance, paint film strength and toughness is obtained by utilizing a redox reaction and adopting a formaldehyde-free reducing agent. The preparation system provided by the invention belongs to a strong acid type emulsion, can react with metal substrates such as a steel plate and the like, is beneficial to demulsification and base material combination of the emulsion in the film forming process, and further improves the compactness, water resistance and chemical resistance of the film.

Owner:泰安聚仁新材料有限公司

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com