Halogenated olefin combined solvent containing 1-chloro-2, 3, 3-trifluoropropene and application thereof

A technology of trifluoropropene and halogenated olefin, which is applied in detergent compositions, non-surface-active detergent compositions, organic non-surface-active detergent compositions, etc., can solve the problems of poor compatibility, low flash point and excessive solubility. Strong and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0054] In the present invention, the preparation method of the halogenated olefin combined solvent containing 1-chloro-2,3,3-trifluoropropene preferably includes the following steps:

[0055] Mix 1-chloro-2,3,3-trifluoropropene, trans-1,2-dichloroethylene and methyl perfluoroheptenyl ether to obtain 1-chloro-2,3,3-trifluoropropene Halogenated olefin combination solvent.

[0056] The present invention does not have special requirements for the mixing method, as long as the mixing method well known to those skilled in the art can be used, such as stirring and mixing.

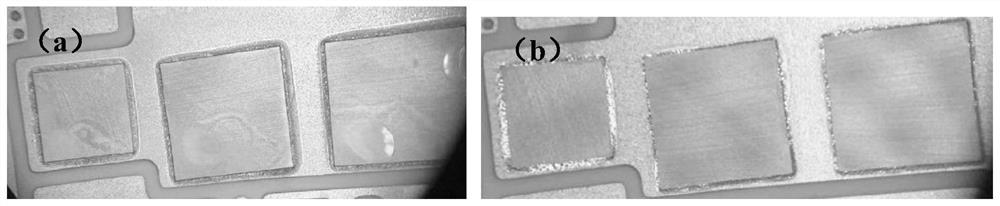

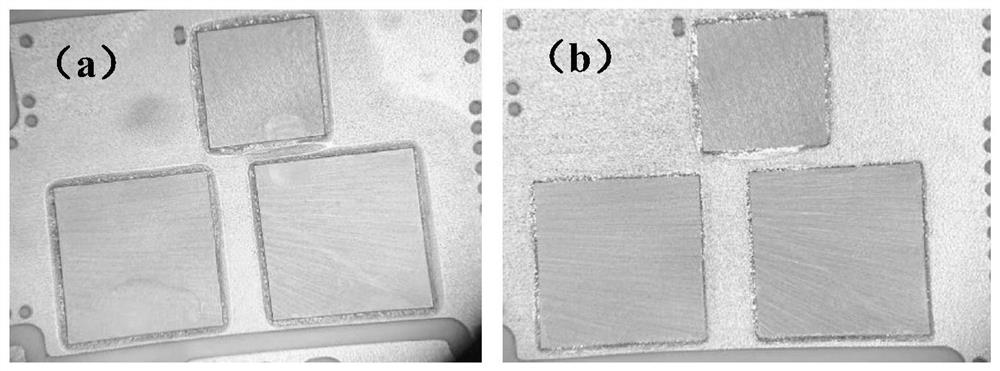

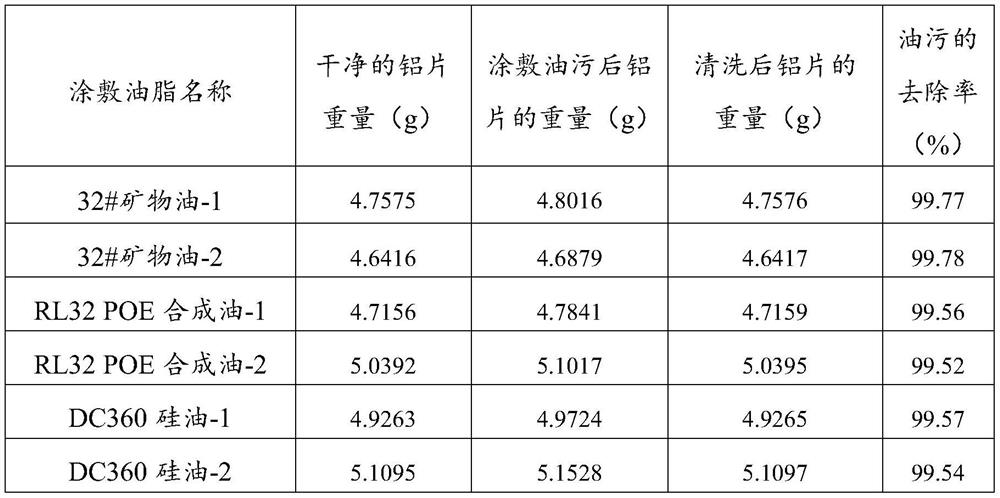

[0057] The present invention provides the application of the above-mentioned halogenated olefin combined solvent containing 1-chloro-2,3,3-trifluoropropene in cleaning agents, diluents and aerosols. In the present invention, the cleaning agent is a cleaning agent for degreasing metal parts, removing flux for electronic components and sensitive plastic parts. When the halogenated olefin combined solvent of the present i...

Embodiment 1

[0065] Weigh 300 grams of 1-chloro-2,3,3-trifluoropropene, 4000 grams of trans-1,2-dichloroethylene and 160 grams of methyl perfluoroheptenyl ether, and mix them to prepare a mixture containing 1-chloro-2, The halogenated olefin combination solvent of 3,3-trifluoropropene; wherein 1-chloro-2,3,3-trifluoropropene is trans 1-chloro-2,3,3-trifluoropropene with a purity of 95%.

[0066] The flash point standard test method ASTM D56-05 (2010) of the Tag closed cup tester is used to determine the flash point of the obtained halogenated olefin combination solvent. After testing, the present invention contains 1-chloro-2,3,3-tri The halogenated olefin combination solvent of fluoropropylene has no flash point.

Embodiment 2

[0078] Weigh 3500 grams of 1-chloro-2,3,3-trifluoropropene, 4000 grams of trans 1,2-dichloroethylene, 200 grams of methyl perfluoroheptenyl ether and 200 grams of isopropanol, and mix them to prepare A halogenated olefin combination solvent of 1-chloro-2,3,3-trifluoropropene, where 1-chloro-2,3,3-trifluoropropene is trans 1-chloro-2,3 with a purity of 95%, 3-Trifluoropropene.

[0079] The flash point standard test method ASTM D56-05 (2010) of the Tag closed cup tester is used to determine the flash point of the obtained halogenated olefin combination solvent. After testing, the present invention contains 1-chloro-2,3,3-tri The halogenated olefin combination solvent of fluoropropylene has no flash point.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com