Assembly type detachable floating bridge

A prefabricated, floating bridge technology, applied in the field of construction engineering, can solve the problems of complex disassembly, low practicability, inconvenient transportation, etc., and achieve the effect of good comprehensive performance, high practicability and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

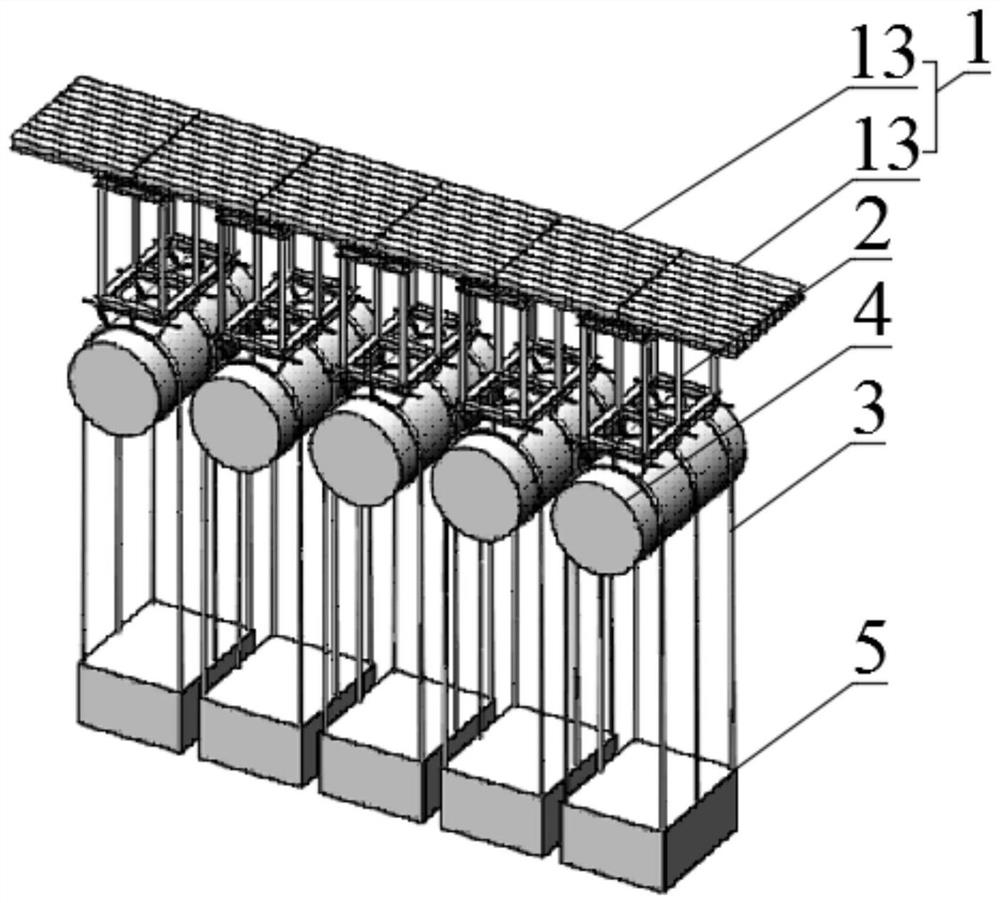

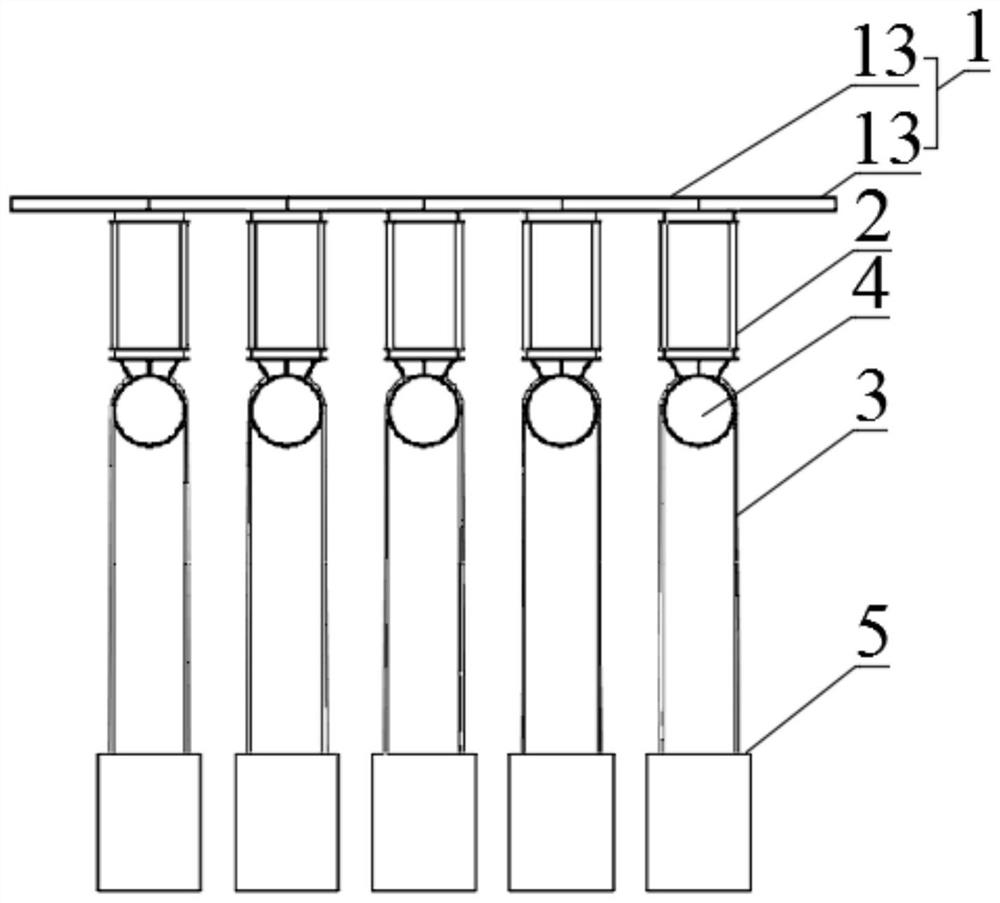

[0047] Please refer to figure 1 with figure 2, Embodiment 1 of the present invention is:

[0048] An assembled detachable pontoon such as figure 1 with figure 2 As shown, it includes a bridge deck 1 , a support 2 , a fixed bracket 3 , an airbag floating body 4 and a counterweight 5 . Wherein, the bottom of the bridge deck 1 is provided with a plurality of supports 2 along the extending direction of the bridge deck 1, the supports 2 are fixedly connected with the bottom of the bridge deck 1, and the end of each support 2 away from the bridge deck 1 corresponds to a fixed bracket 3 Fixedly connected, the airbag floating body 4 is fixed in the fixed bracket 3, and the other end of the fixed bracket 3 is fixedly connected with the counterweight 5. Specifically, the counterweight 5 can use a concrete counterweight 5 . The supporting member 2, the airbag floating body 4 and the counterweight 5 are arranged sequentially from top to bottom to form a laminated structure.

[004...

Embodiment 2

[0051] Please refer to Figure 1 to Figure 6 , the second embodiment of the present invention is:

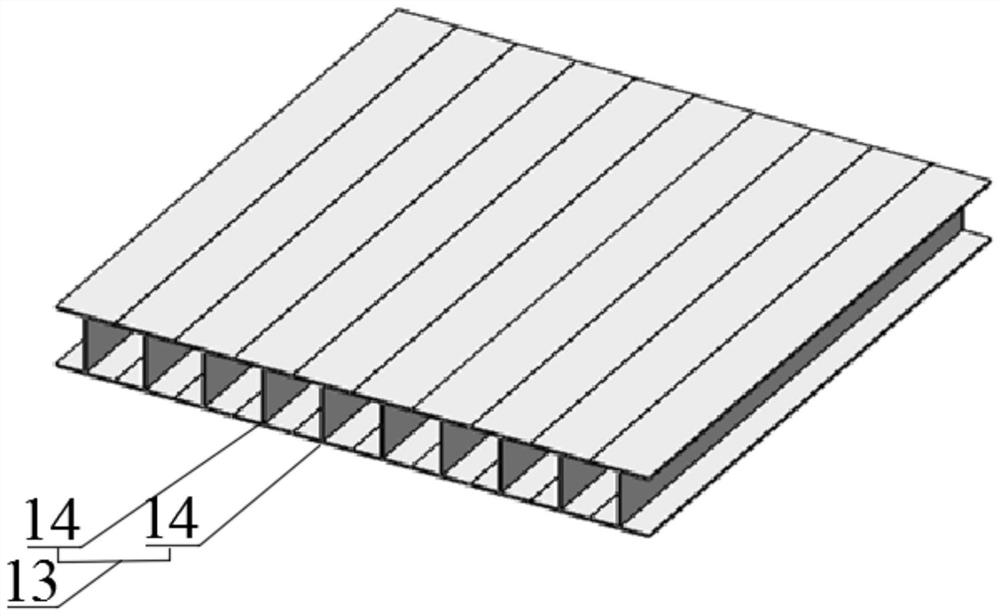

[0052] An assembled detachable pontoon, on the basis of the first embodiment above, such as Figure 5 with Image 6 As shown, the support member 2 includes an upper bottom surface 6 , a lower bottom surface 7 and a round steel pipe 8 . Among them, the upper bottom surface 6 and the lower bottom surface 7 are stacked under the bridge deck 1, and the upper bottom surface 6 and the lower bottom surface 7 are composed of a plurality of I-beams 14 spliced together, and the adjacent I-beams 14 are welded and fixed. The upper bottom surface 6 closely fits and is fixedly connected to the bottom of the bridge deck 1, the side of the upper bottom surface 6 away from the bridge deck 1 is fixedly connected to one end of a plurality of round steel pipes 8, and the other end of the plurality of round steel pipes 8 is fixedly connected to the lower bottom surface 7 , the side of the lower...

Embodiment 3

[0060] Please refer to Figure 7 with Figure 8 , Embodiment three of the present invention is:

[0061] An assembled detachable floating bridge, on the basis of the above-mentioned embodiment one or two, such as Figure 7 with Figure 8 As shown, the fixed bracket 3 includes a connecting plate 9 , a support bar 12 , a ring portion 10 and a chain portion 11 . Wherein, the end face of the end surface of the support member 2 away from the bridge deck 1 is closely attached to and fixedly connected to the connecting plate 9, and the side of the connecting plate 9 away from the support member 2 is fixedly connected to the annular part 10 through a plurality of support bars 12, all The extension direction of the support bar 12 is all towards or deviates from the center of the circle of the ring part 10, the ring part 10 is fixedly connected with one end of the chain part 11, the airbag floating body 4 is fixed in the ring part 10, and the other end of the chain part 11 is connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com