Karst landform tunnel energy-gathered water pressure smooth blasting structure and method

A technology of smooth blasting and karst, which is applied in blasting, tunneling, earthwork drilling and mining, etc. It can solve the problems of insufficient safety, too dense holes in smooth blasting, and high construction costs, so as to reduce labor force, improve economic benefits, The effect of speeding up the construction progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

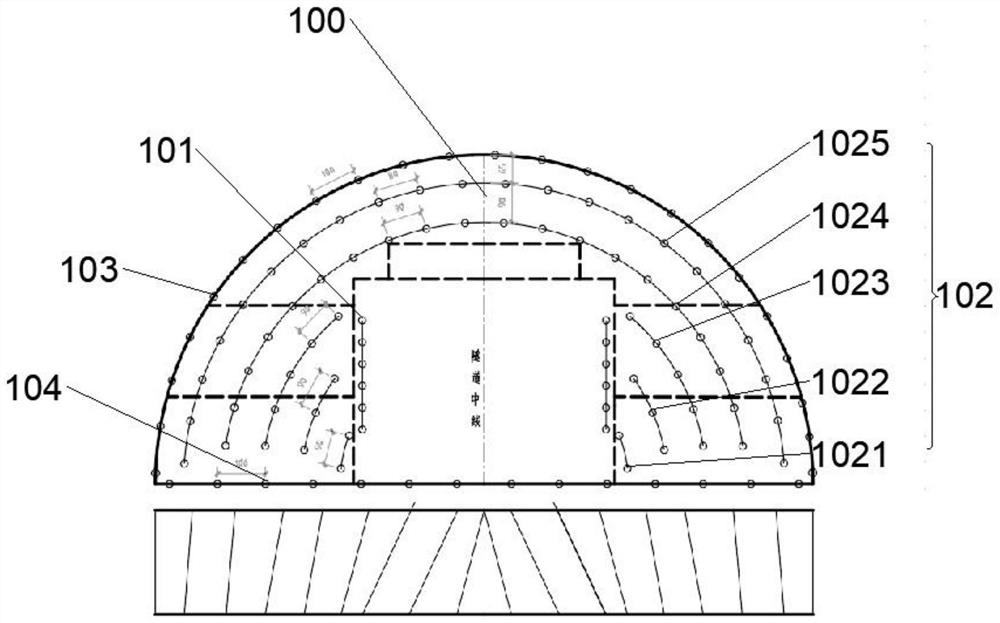

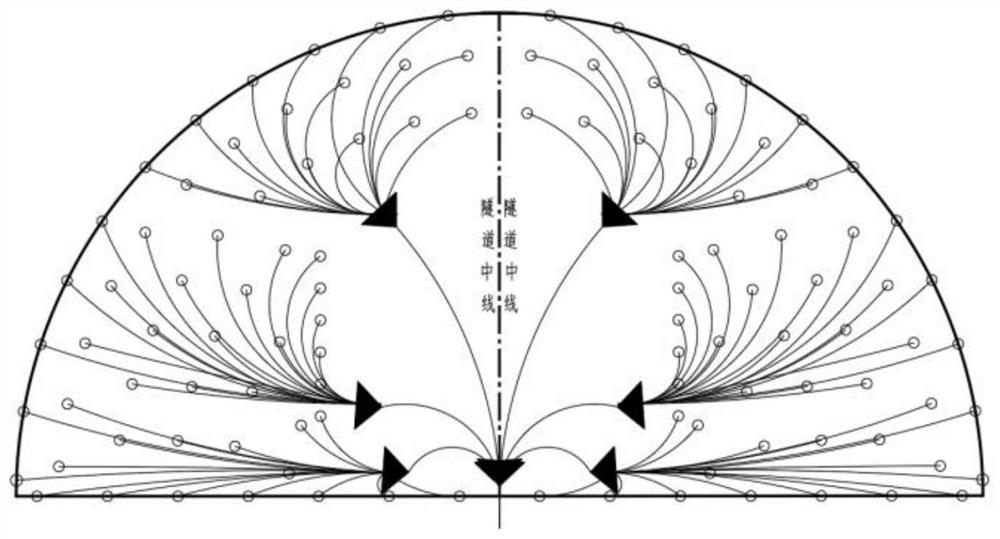

[0036] This embodiment provides a karst landform tunnel energy-concentrating water pressure smooth surface blasting structure, including a cut hole 101, an auxiliary hole 102, a peripheral hole 103 and a floor hole 104; wherein,

[0037] Cutting eyes 101 are symmetrically arranged on both sides of the tunnel center line 100, the side of the cut hole 101 away from the tunnel center line 100 is provided with an auxiliary eye 102, and the side of the auxiliary eye 102 far away from the tunnel center line 100 is provided with a peripheral eye 103; the bottom plate eye 104 is provided at the bottom of the tunnel section. The specific setting parameters are shown in Table 1.

[0038] Table 1 Parameters of blastholes with concentrated energy water pressure light explosion on steps

[0039] pop eye depth m angle Spacing cm Number Cutout 2.8 70° / 12 auxiliary eye 2.6 90° 80-90 62 peripheral eye 2.6 85° 100 22 Bottom hole 2.6 87° 10...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vertical depth | aaaaa | aaaaa |

| Vertical depth | aaaaa | aaaaa |

| Vertical depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com