Rotational flow blade type mixer

A swirl blade and mixer technology, which is used in machines/engines, mufflers, exhaust gas treatment, etc., can solve the problems of insufficient airflow velocity, insufficient mixing path, insufficient urea crushing, and affecting the effect of urea crushing and decomposition, so as to speed up the airflow. Speed, increase mixing path, urea crushing and decomposition effect enhanced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

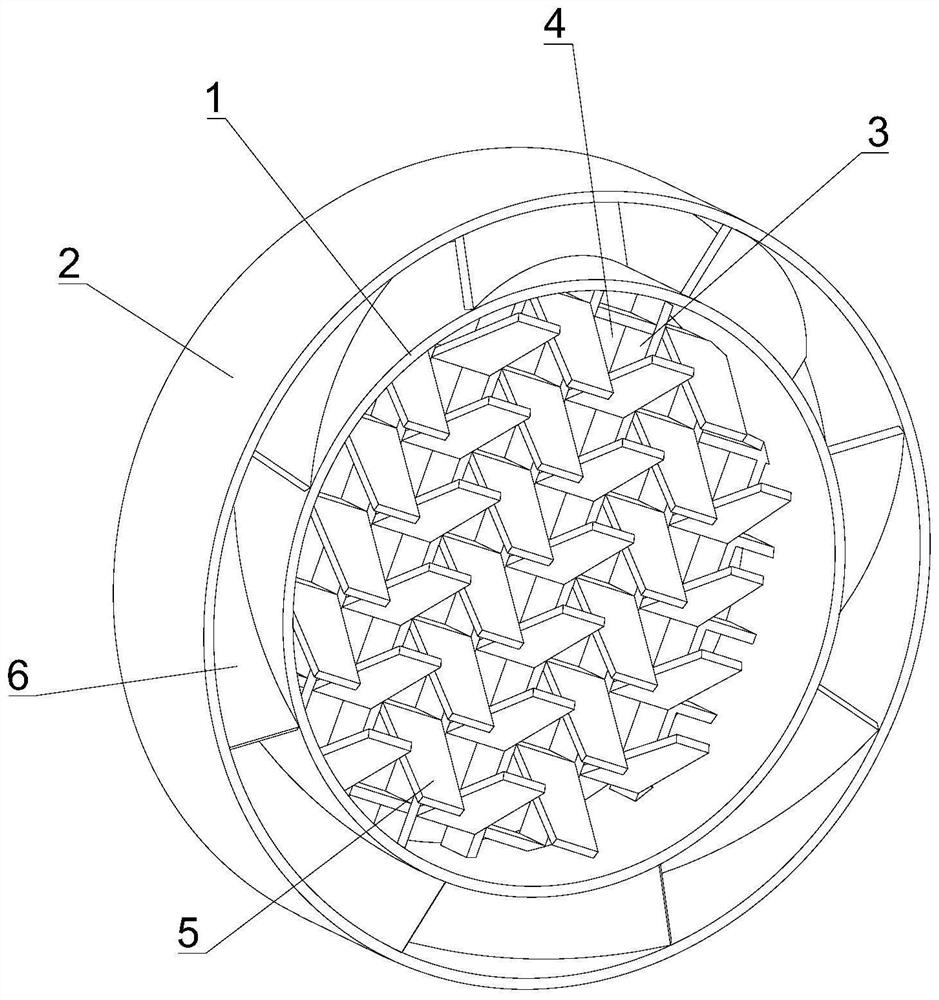

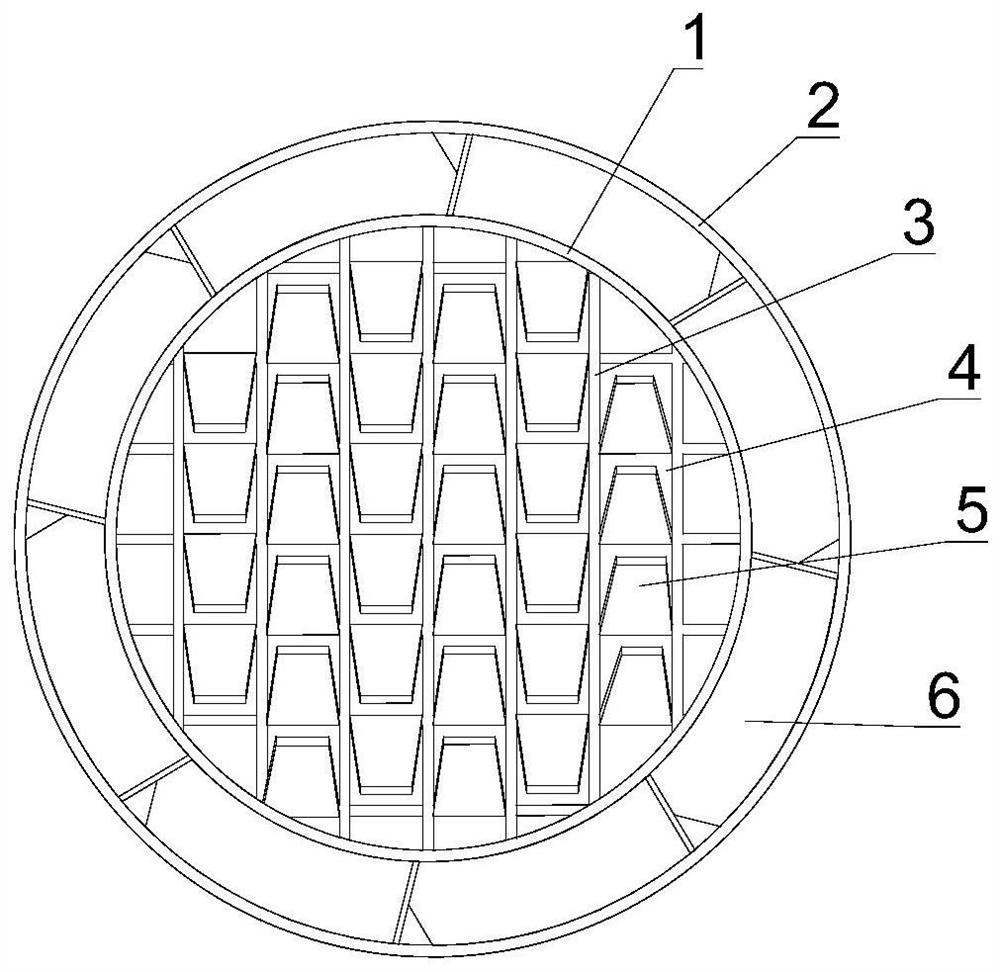

[0017] see Figures 1 to 3 As shown, this embodiment provides a swirling vane mixer, which includes an inner cylinder 1 and an outer cylinder 2 coaxially arranged, and a grid frame 3 is arranged in the inner cylinder 1, and the grid frame 3 will The chamber of the inner cylinder body 1 is divided into flow channels 4 one by one.

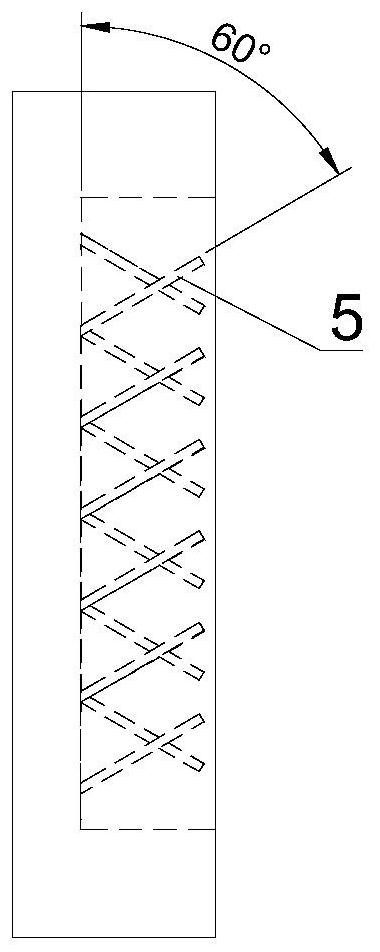

[0018] The frame of each flow channel 4 extends upwards with inclined blades 5, and the inclined blades 5 block and break the urea solution in the flow channel 4 therein. In order to facilitate forming and reduce the difficulty of forming complex shaped blades, each inclined blade 5 is uniformly arranged on the frame edge of the horizontal row or the vertical frame edge, and the orientation of the inclined blades 5 in adjacent rows or columns is opposite. This shape is en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com