Rolling bearing

A technology of rolling bearings and rolling elements, applied in the field of bearings, can solve problems such as shortening the service life of bearings, and achieve the effects of prolonging the service life, suppressing temperature rise, and reducing accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

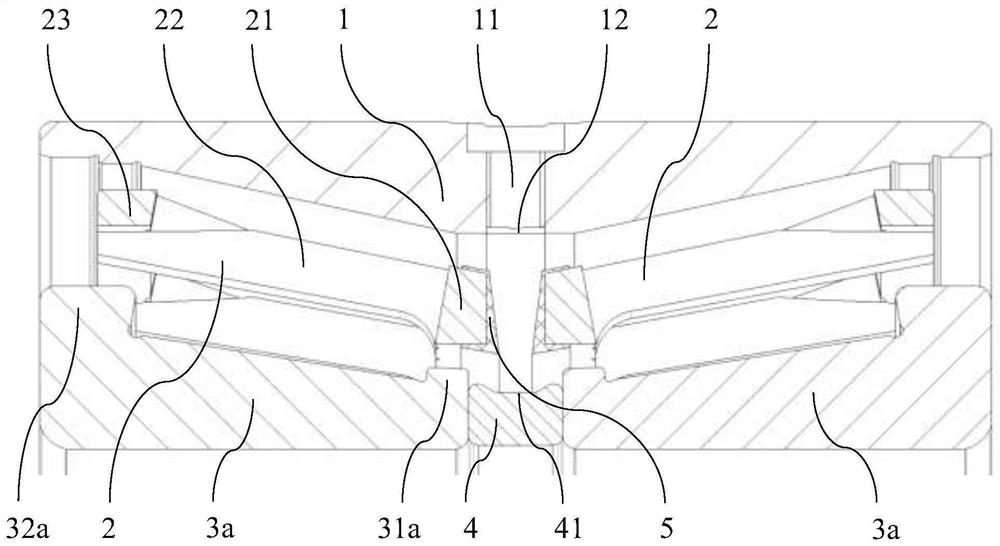

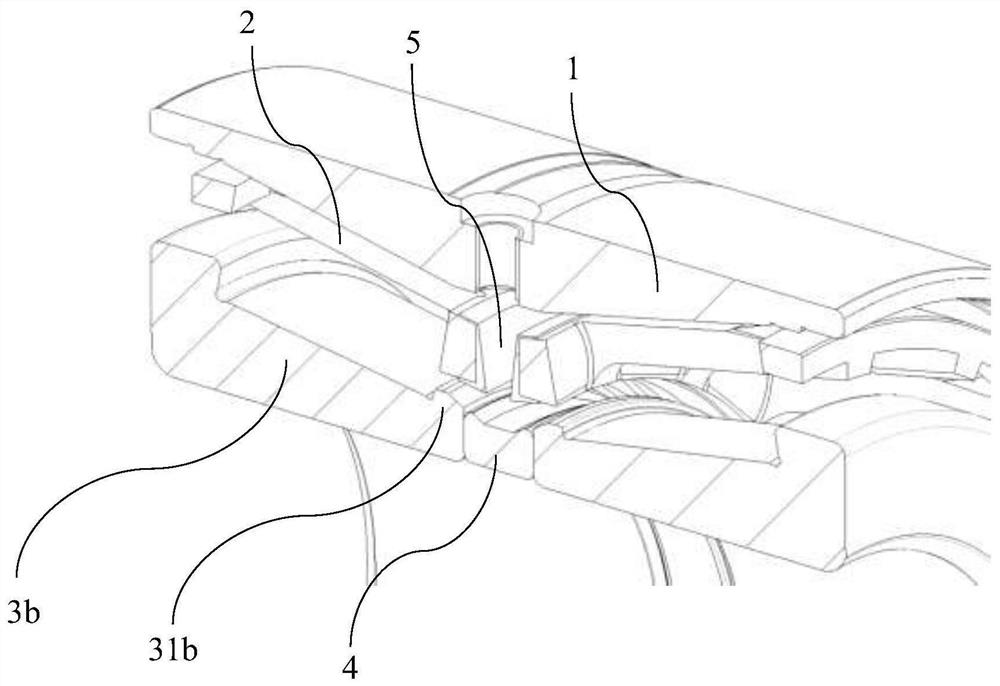

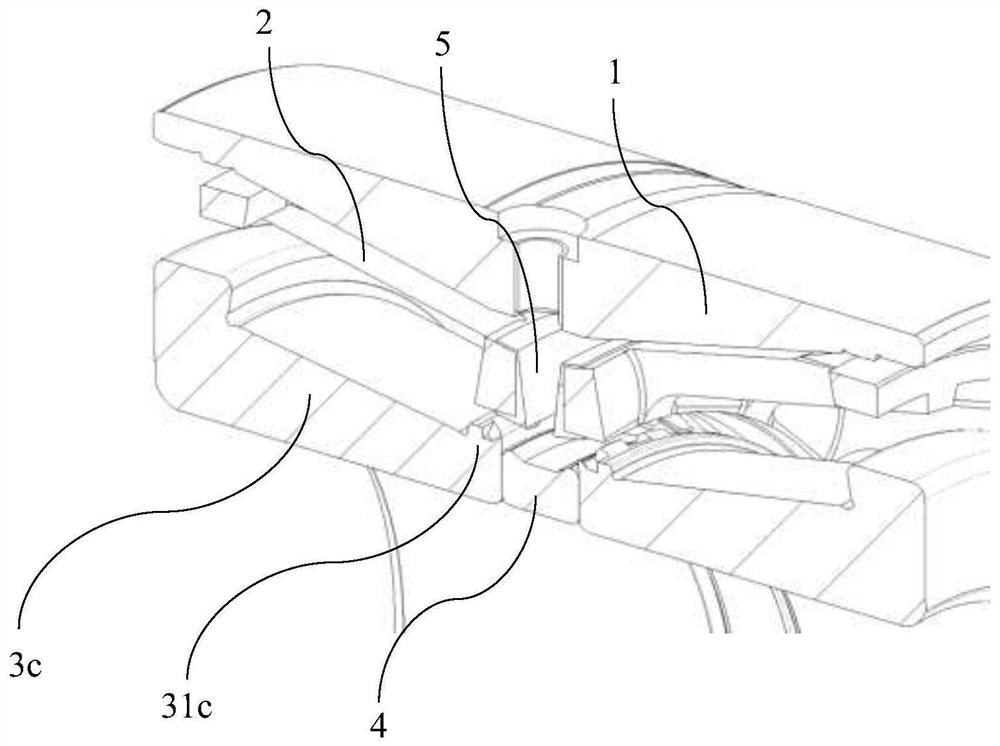

[0031] figure 1 A half-sectional view of a rolling bearing according to a first preferred embodiment of the present invention is shown. The rolling bearing according to the first preferred embodiment is configured as a double-row tapered roller bearing. In this case, the rolling bearing can be used, for example, as a wheel set bearing in a train.

[0032] Such as figure 1 As shown, the rolling bearing includes an outer ring and an inner ring, two rows of rolling elements (not shown) in the form of tapered rollers arranged radially between the outer ring and the inner ring, and two cages for holding one row of rolling elements respectively 2.

[0033] The outer ring is arranged on the radially outer side of the two rows of tapered rollers. In this embodiment, the outer ring is constituted by a separate outer ring component 1 , wherein the radially inner side of the outer ring component 1 is configured with two inner raceways for tapered rollers spaced apart in the axial dir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com