Vertical organic heat carrier boiler with boiler barrel

A drum and boiler technology, which is applied in the direction of boiler drum/box header, preheating, feed water heater, etc., can solve the problems of imperfect design of drum and affecting boiler water circulation efficiency, etc., to optimize water circulation power and improve Water cycle efficiency, the effect of improving the drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

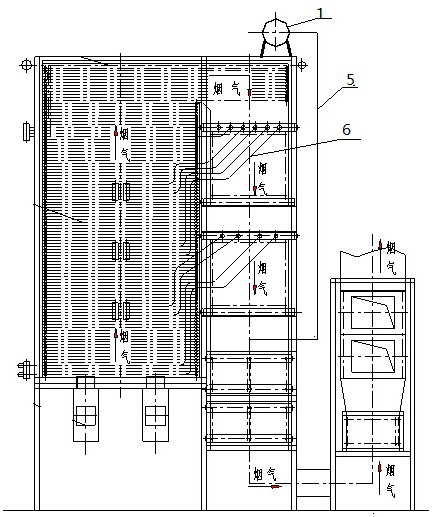

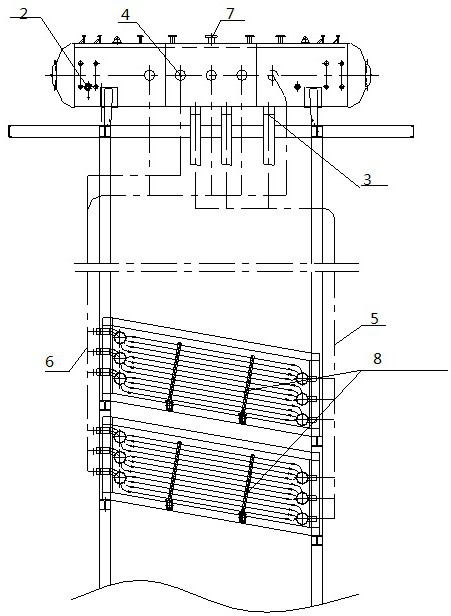

[0016] Such as figure 1 As shown, a vertical organic heat carrier boiler with a drum, the drum 1 includes a water inlet valve 2, a water outlet valve 3, a steam inlet valve 4 and a main steam valve 7, and the water inlet valve 2 is connected with the coal-saving The water outlet valve 3 is connected with the descending pipe 5 of the convection section 8, the steam inlet valve 4 is connected with the ascending pipe 6 of the convection section 8, and the drum 1 is fixed to the boiler through the drum support. The top of the steel frame; by arranging the boiler drum at the top of the boiler steel frame, the drop of water flow is improved, the water cycle power is effectively optimized, and the water cycle efficiency of the boiler is improved.

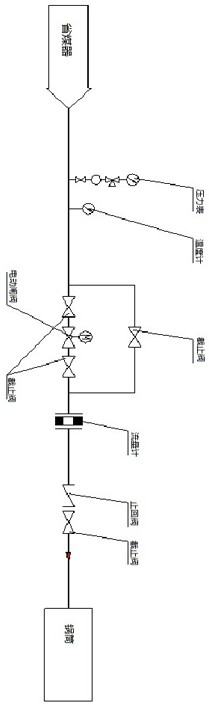

[0017] The connection between the water inlet valve 2 and the economizer is as follows: the economizer is sequentially connected to a pressure gauge, a thermometer, a first cut-off valve, an electric gate valve, a second cut-off valve, a f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com