A carbon spring steel wire drawing lubricating cooling device and drawing production line

A carbon spring steel wire, lubrication and cooling technology, applied in the field of carbon spring steel wire production equipment, can solve the problems of low wire feeding speed, slow production efficiency, small deformation, etc., to reduce maintenance, prevent sticking, and uniform deformation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

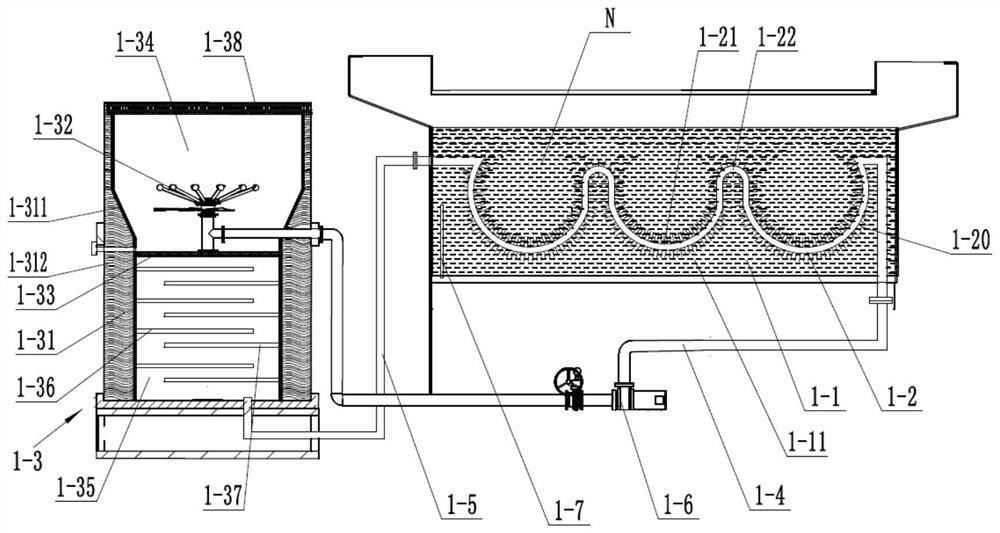

[0046] see Figure 1-6 , a carbon spring steel wire drawing lubricating and cooling device, which includes a lubricating cooling box 1-1, a heat exchange tube 1-2, a cooling water tower 1-3, a first pipeline 1-4, a second pipeline 1-5, and a variable frequency pump 1-6, temperature sensor 1-7, frequency converter and controller.

[0047] The lubricating and cooling box 1-1 has a wire-drawing working chamber 1-11, and the wire-drawing working chamber 1-11 contains a wire-drawing lubricant N.

[0048] Specifically, the wire drawing lubricant N is a liquid lubricant. Since the drawing lubricant N can be selected from materials in the prior art, it will not be described in detail.

[0049] The heat exchange tube 1-2 is located in the lubrication cooling box 1-1.

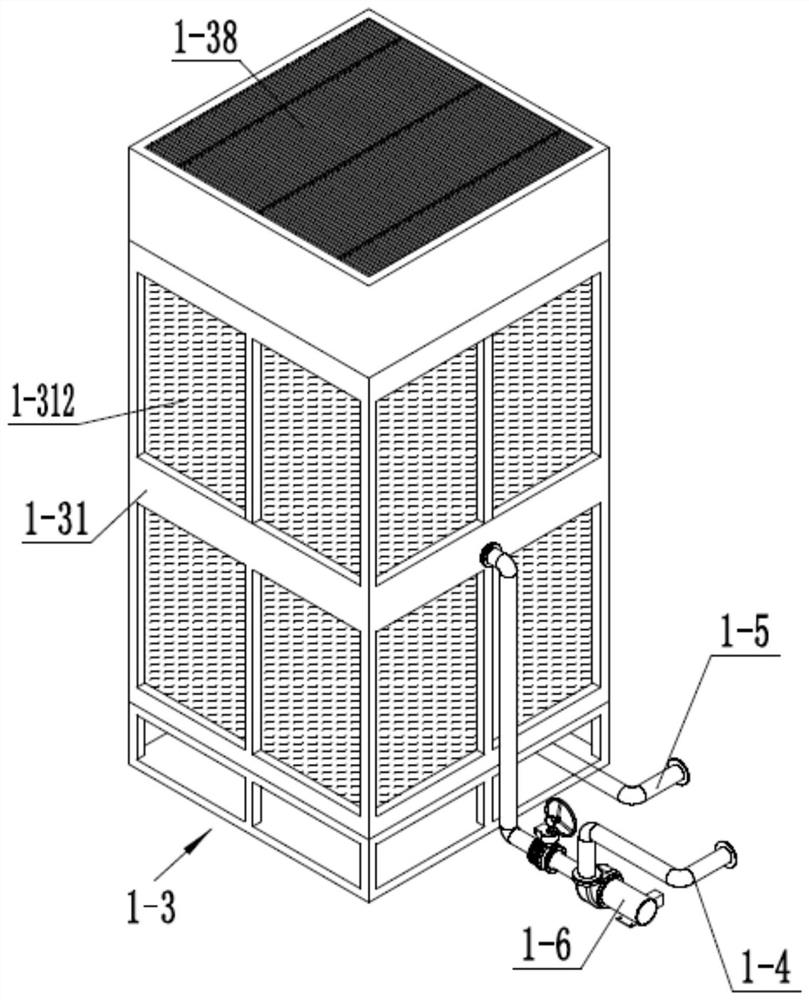

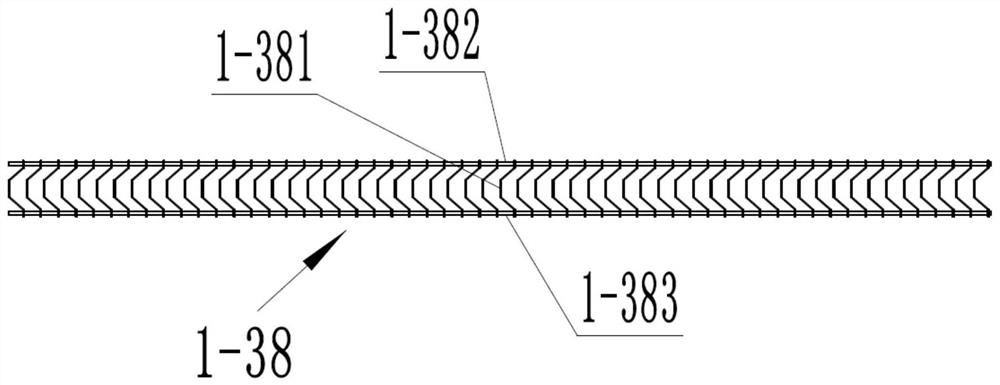

[0050] The cooling water tower 1-3 includes a tower body 1-31, a water spray assembly 1-32, and a filter layer 1-33; the tower body 1-31 has an inner cavity, which is separated by the filter layer 1-33 into The upper...

Embodiment 2

[0070] see Figure 7-13 , a wire drawing production line, which includes a frame 2, a steel wire introduction mechanism 3, an inner wire winding wheel 4, a wire drawing mechanism 5, a steel wire export mechanism 6, a wire removal lubricant mechanism 7, an outer wire winding wheel 8, a wire guide wheel 9, The wire-receiving shaft 10 and the carbon spring steel wire drawing cooling device described in the first embodiment.

[0071] see Figure 7-11 , the two sides of the top of the lubricating cooling box 1-1 are respectively provided with a feed channel 1-12 and a discharge channel 1-13. The steel wire introduction mechanism 3 is arranged in the feed channel 1-12, and the steel wire lead-out mechanism 6 is arranged in the discharge channel 1-13.

[0072] see Figure 7 with 11 There are N number of the inner wire winding wheels 4, each of the inner wire winding wheels 4 is arranged side by side in the horizontal direction and at intervals in the lubricating cooling box 1-1, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com