Rotational flow disturbance device and heat exchange pipe structure

A technology of heat exchange tubes and swirling flow, applied in the field of heat exchange tubes, can solve the problems of large flow pressure drop of heat exchange tubes, achieve the effects of solving excessive flow pressure drop, compact and reliable structure, and improving effective utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

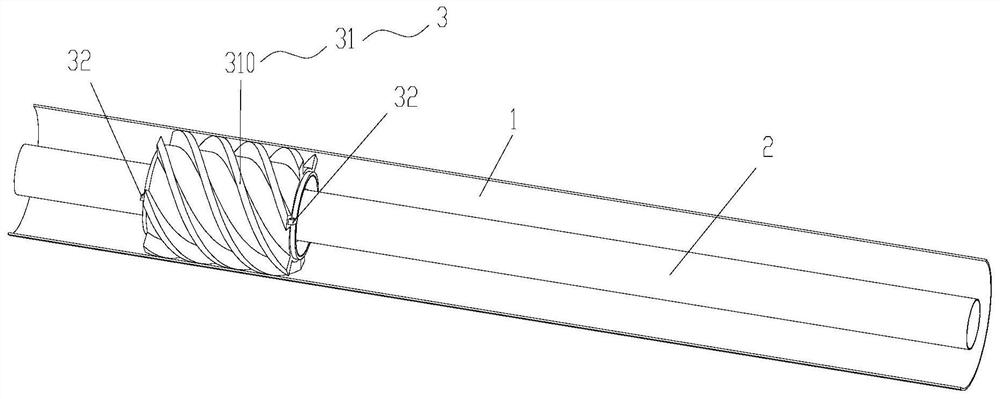

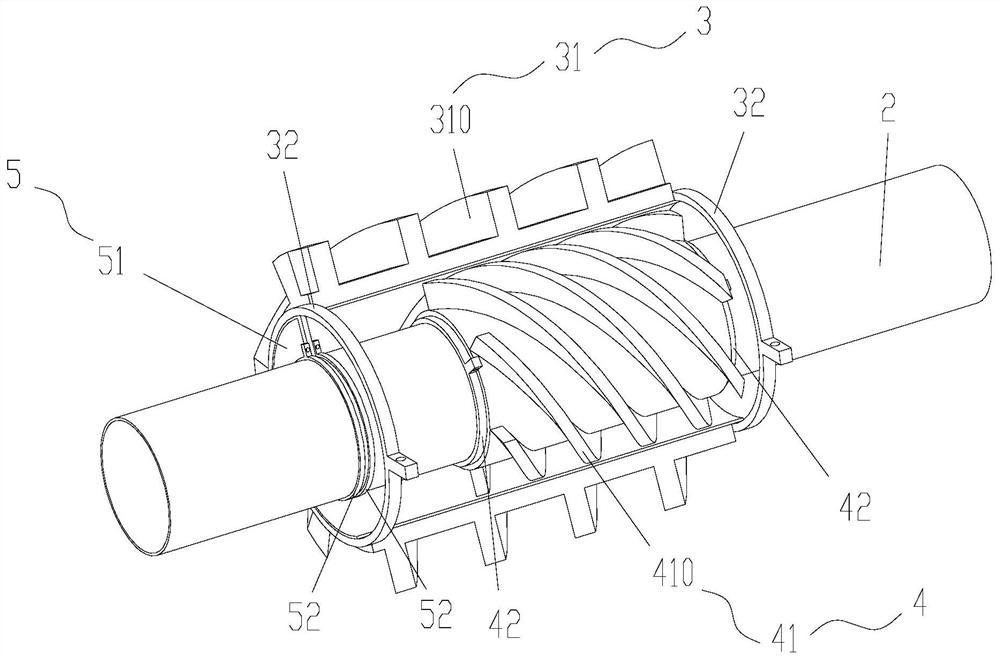

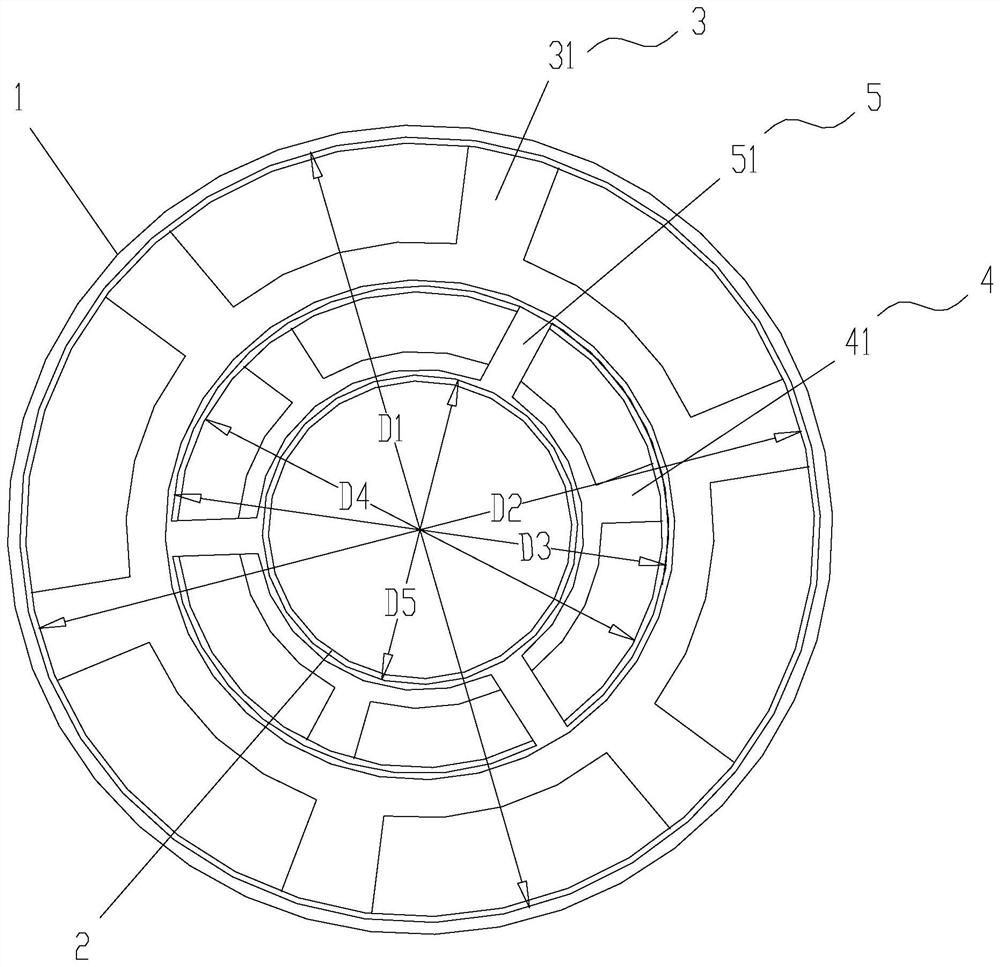

[0032] Such as Figure 1 to Figure 8As shown, the present invention provides a swirl disturbance device for installation in a heat exchange tube structure, the heat exchange tube structure includes a first tube 1 and a second tube 2 pierced in the first tube 1; the first The pipe 1 and the second pipe 2 are arranged at intervals to form an annular flow path for the flow of the first fluid; the second pipe 2 is used for the flow of the second fluid; the temperature of the first fluid is different from the temperature of the second fluid The same; the swirl disturbance device includes: a first swirl assembly 3 and a second swirl assembly 4, the position between the first swirl assembly 3 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com