Mute relay

A relay and mute technology, applied in relays, electromagnetic relays, electromagnetic relay details, etc., can solve the problem of easy deformation of elastic terminals, and achieve the effect of improving supporting force, increasing current-carrying cross-sectional area, and improving rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

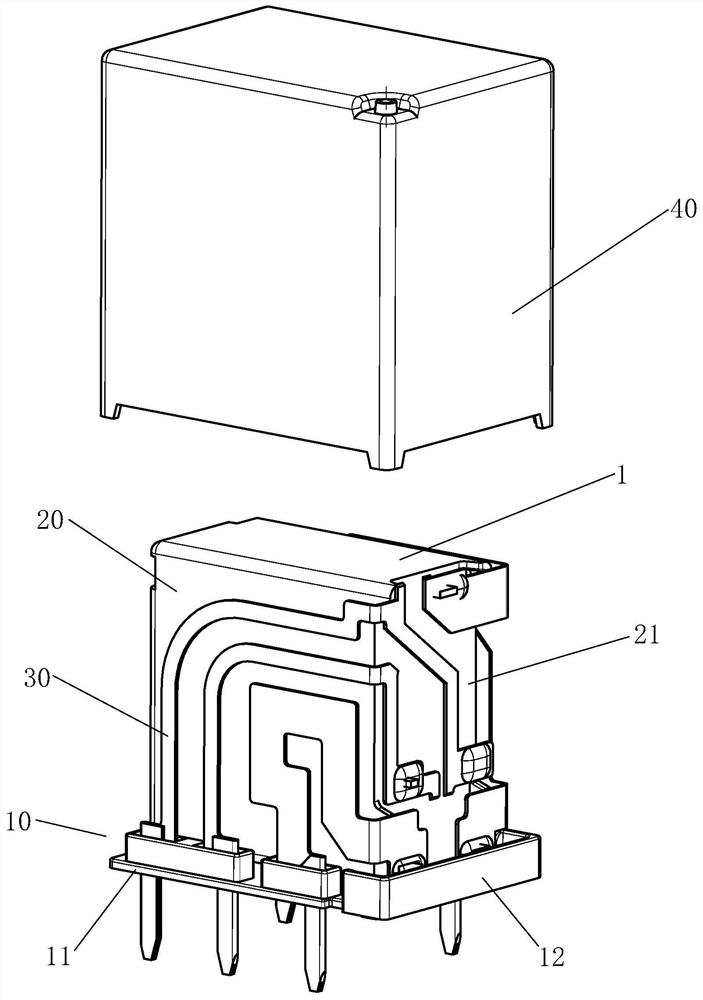

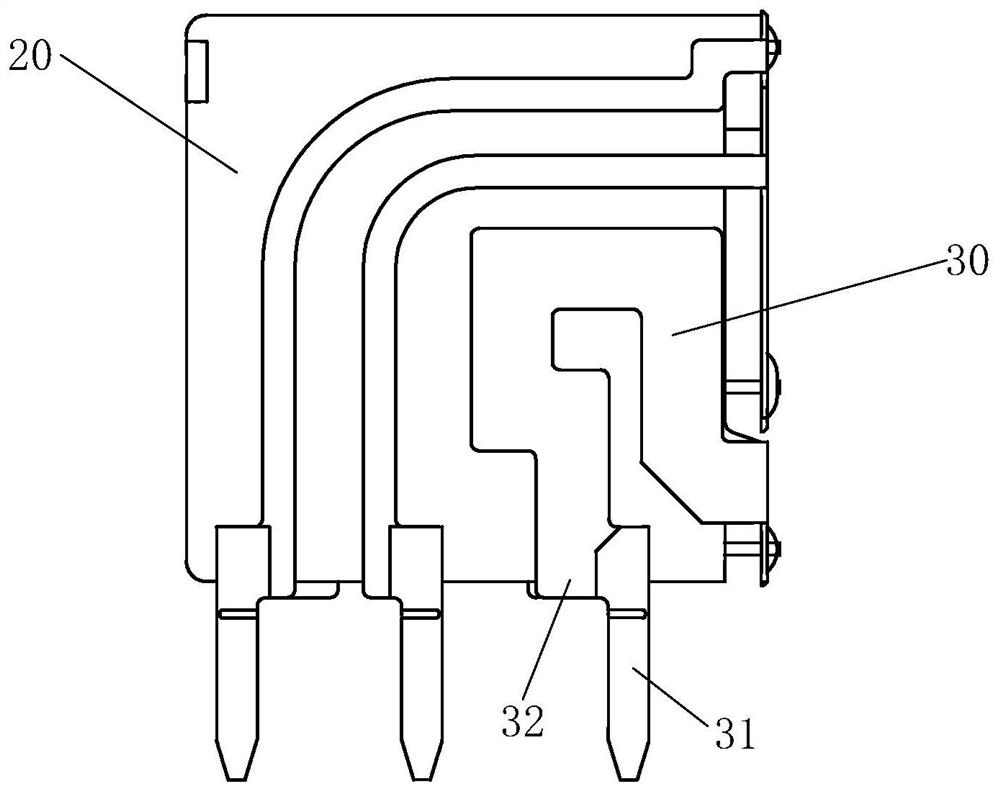

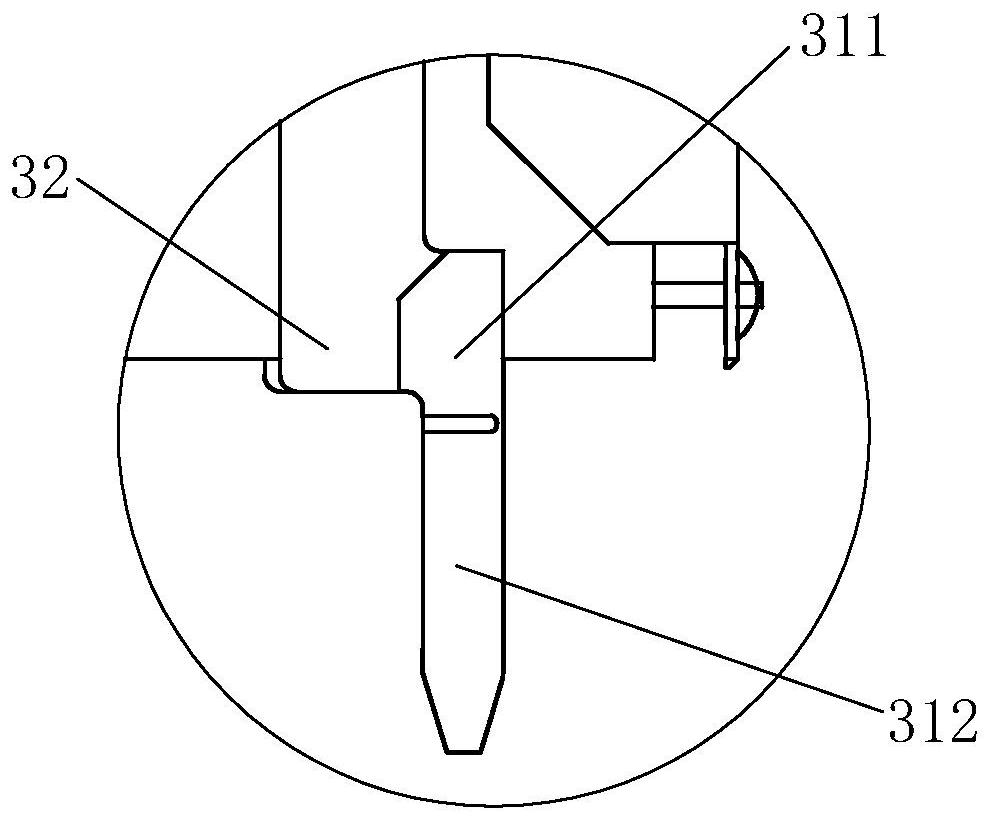

[0045] Examples, see Figure 1-Figure 20 As shown, a silent relay of the present invention includes a base 10, a relay body 20, a plurality of elastic lead-outs 30 and a housing 40, and the first ends of each elastic lead-out 30 are electrically connected to corresponding lead-out pins on the relay body 20 respectively. ; The base 10 is provided with a number of installation grooves 111 corresponding to the plurality of elastic lead-out ends 30 one by one, and each installation groove 111 includes a blind hole portion 1111 with a closed bottom end and a through hole portion 1112 that penetrates up and down, and the blind hole portion 1111 and the through hole portion 1112 are distributed along the length direction of the installation groove 111, and the blind hole portion 1111 and the through hole portion 1112 are laterally connected; the second end of each elastic lead-out end 30 has a lamination structure 31 distributed along its width direction. and the step structure 32, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com