Prepared vegetable raw material cooking equipment and cooking method

A technology of cooking equipment and raw materials, which is applied in cooking equipment and cooking fields of prefabricated vegetable raw materials, can solve the problems of uneven heating of raw materials, inability to add and alarm, and inability to move, so as to reduce the possibility of burns and reduce the steps of operation , good practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

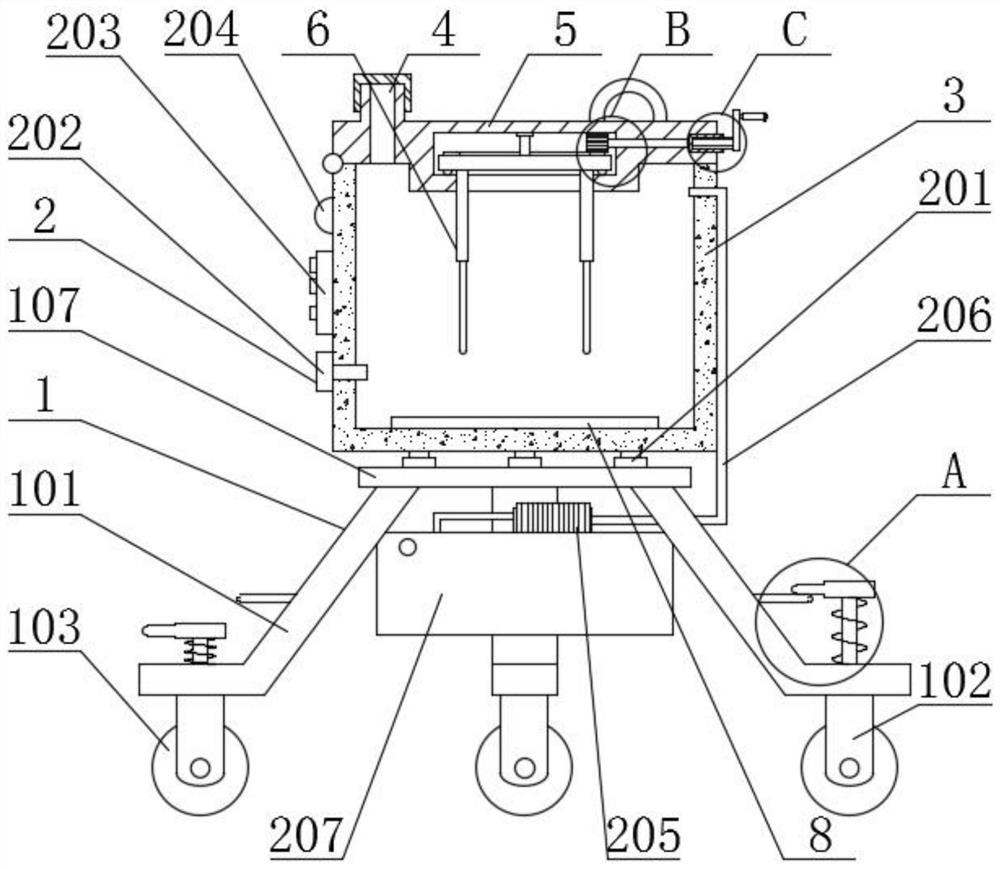

[0031] see Figure 1-7 , the present invention provides a technical solution:

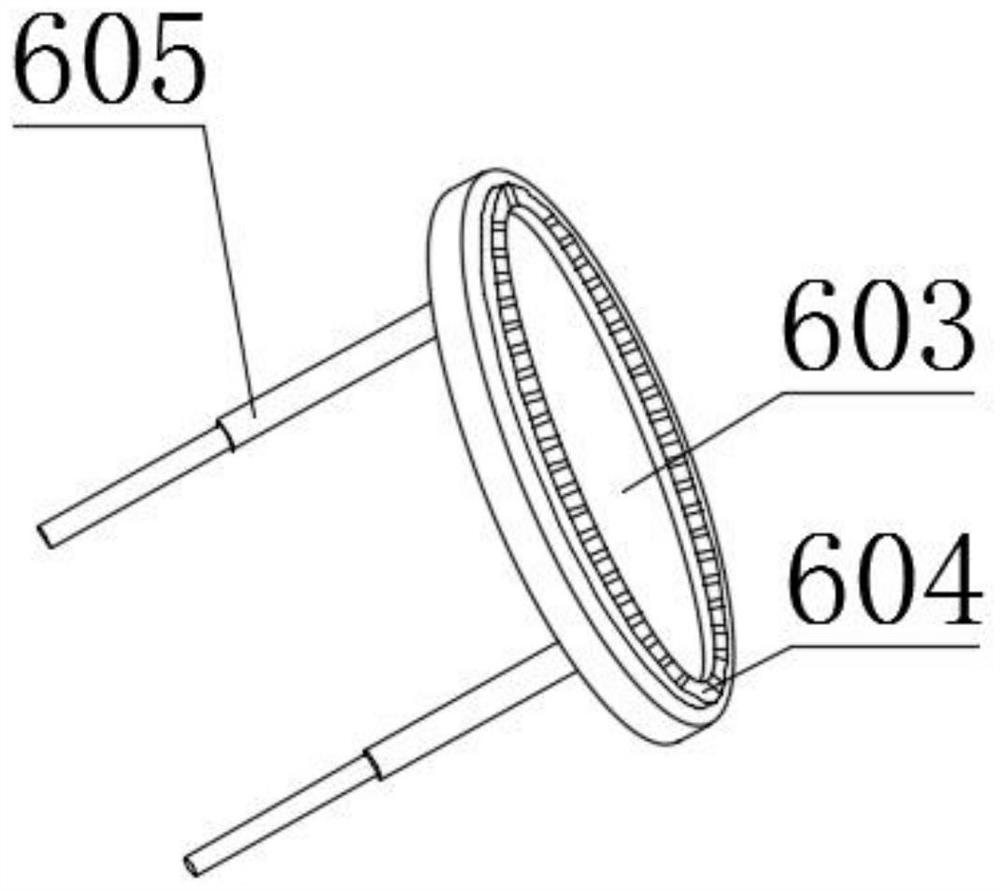

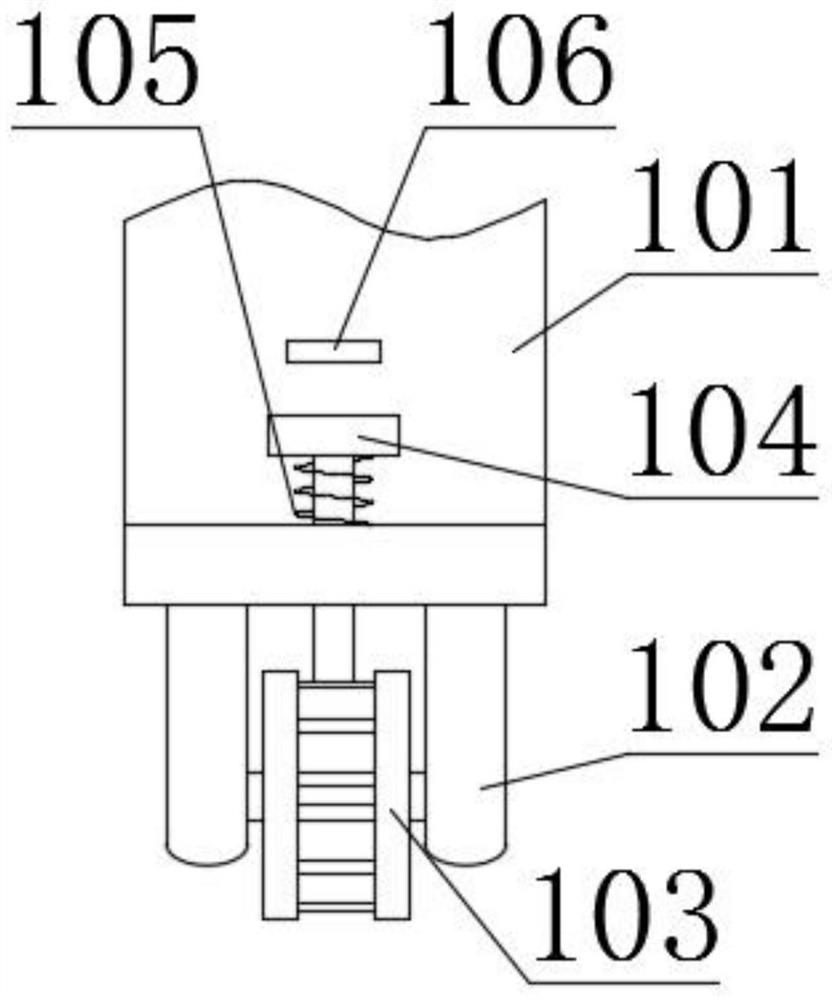

[0032] Cooking equipment for prefabricated vegetable raw materials, comprising a cooking cylinder 3, a heating plate 8 fixedly arranged inside the bottom end of the cooking cylinder 3, an opening cover 5 connected to the top of the cooking cylinder 3 through hinge rotation, and an exhaust cap provided inside the opening cover 5 4. The opening cover 5 is provided with an internal rotation mechanism 6, the lower end of the cooking cylinder 3 is provided with a mobile positioning mechanism 1, and the cooking cylinder 3 is provided with a detection and adjustment mechanism 2. The internal rotation mechanism 6 includes a turntable 603 and a rotating column 602, and the turntable 603 The rotation is arranged at the inner center position of the opening cover 5, the bottom end of the turntable 603 is fixedly connected with a stirring telescopic rod 605, and the stirring telescopic rod 605 is rotatably arra...

Embodiment 2

[0035] Embodiment 2: In this embodiment, the same parts as those in Embodiment 1 will not be repeated. The difference is that when the moisture in the cooking cylinder 3 is completely evaporated, the cooked food will appear burnt. In order to prevent this Phenomenon, when the weight of the cooking cylinder 3 is reduced to the weight set by the control panel 203 before, the control panel 203 can also control the water pump 205 to work, and the water pump 205 will extract the water inside the water tank 207 and inject it into the cooking pot through the water pipe 206. The inner side of the cylinder 3 realizes adding water to the cooked food, thereby preventing burnt burns, and has good practicability.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com