Bottom cleaning system and bottom cleaning method for inside-in and outside-out type drum-shaped filter screen

A technology for cleaning systems and filter screens, applied in separation methods, chemical instruments and methods, filtration and separation, etc., can solve problems such as insufficient cooling water flow, ineffective cleaning, and marine organisms invading, so as to reduce manpower and material costs, Maintain safety and reliability and ensure normal operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

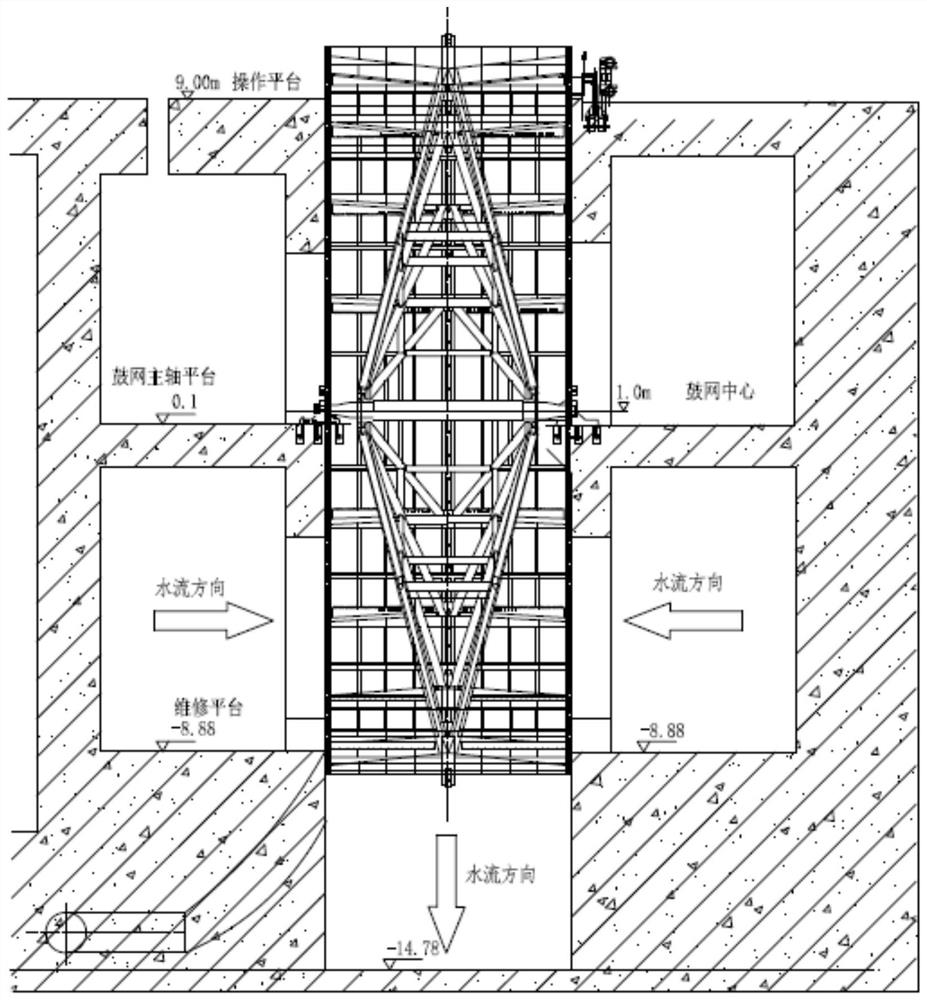

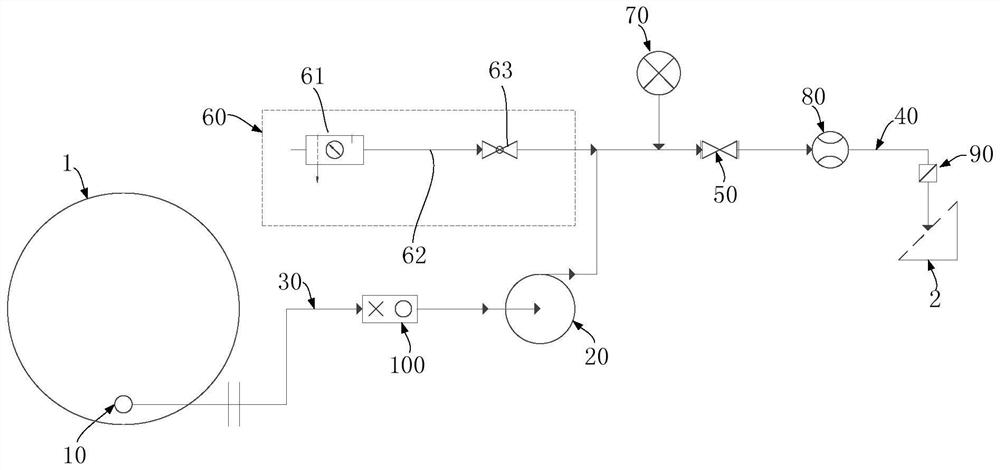

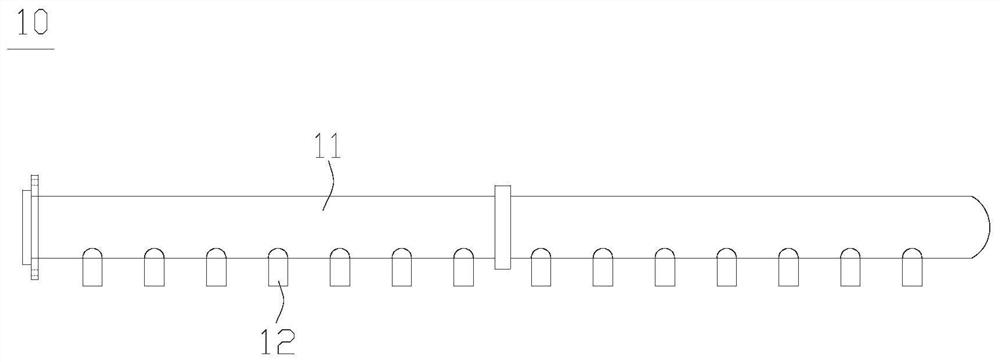

[0031] Such as figure 2 As shown, the bottom cleaning system of the inner-in-out drum filter screen of the present invention may include a suction pipe row 10 , a sewage pump 20 , an input pipeline 30 , an output pipeline 40 and a control valve 50 . The suction pipe row 10 is arranged in the bottom of the drum filter 1, the sewage pump 20 is arranged on the -8.88m maintenance platform of the drum filter, and the input pipe 30 is connected to the inlet end of the suction pipe row 10 and the sewage pump 20 Between, the output pipeline 40 is connected between the outlet end of the sewage pump 20 and the sewage system of the power station; the control valve 50 is arranged on the output pipeline 40 to control the on-off of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com