Rotor spot welding device

A spot welding device and rotor technology, applied in welding equipment, resistance welding equipment, metal processing equipment, etc., can solve the problems of complicated rotor operation steps, and achieve the effect of complete automation of the welding process and realization of the welding process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following is further described in detail through specific implementation methods:

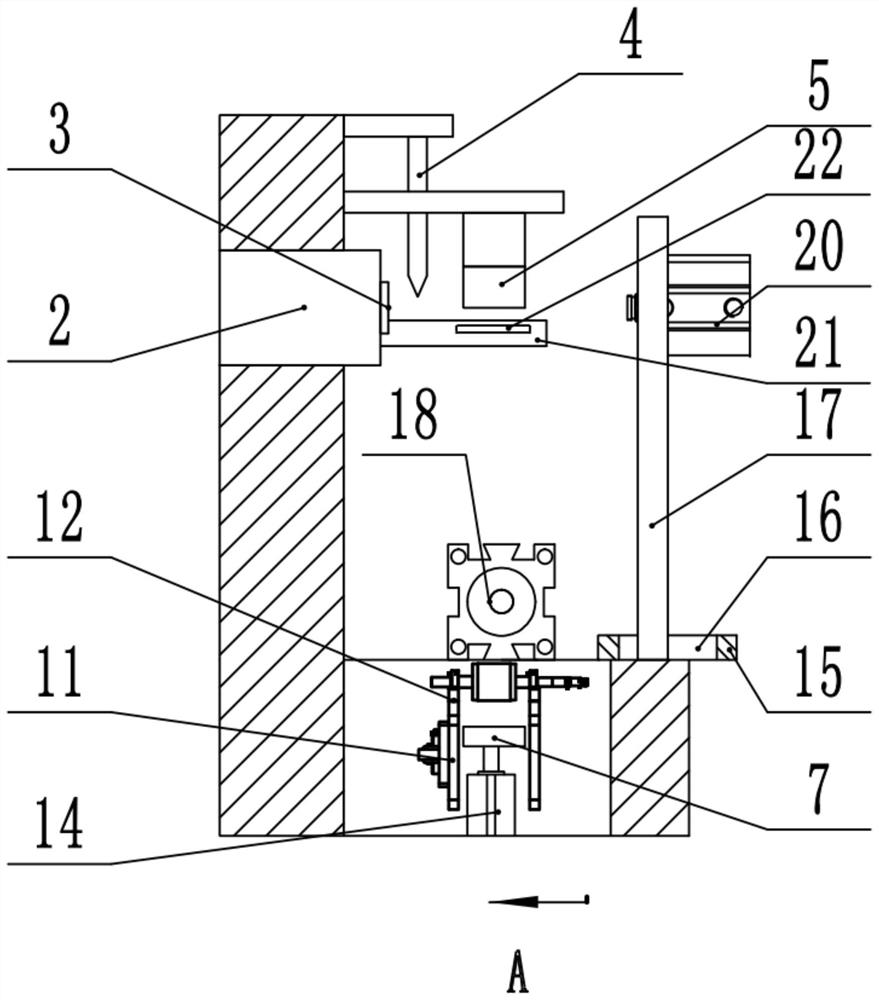

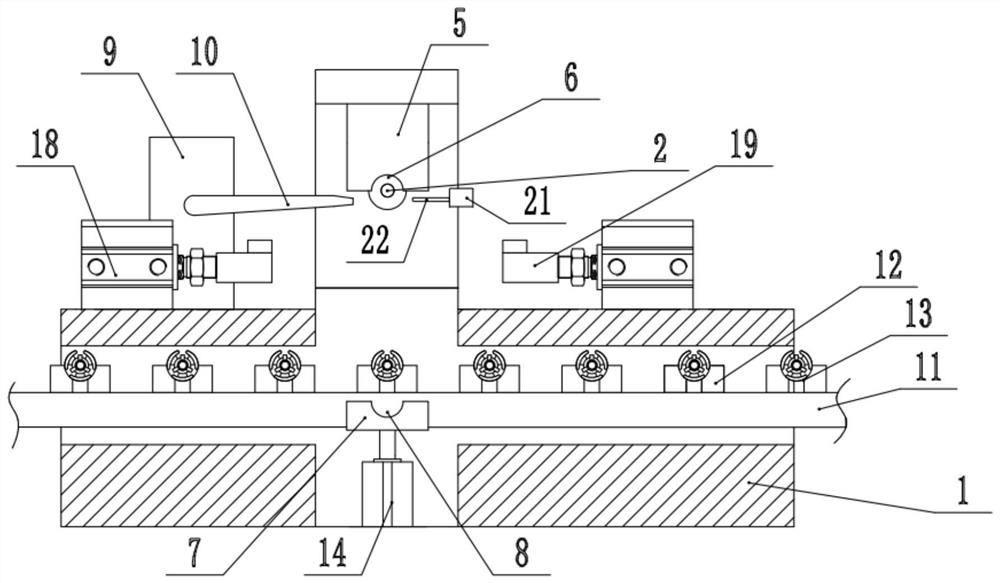

[0029] The reference signs in the drawings of the description include: workbench 1, servo motor 2, matching block 3, welding head 4, upper mold 5, first groove 6, lower mold 7, second groove 8, air pump 9, guide Air pipe 10, conveyor chain 11, bracket seat 12, third groove 13, first telescopic cylinder 14, load plate 15, slideway 16, support plate 17, third telescopic cylinder 18, block 19, second telescopic cylinder 20 , positioning rod 21, positioning block 22.

[0030] The embodiment is basically as attached figure 1 with attached figure 2 Shown: The rotor spot welding device includes a workbench 1, a servo motor 2 is fixed by bolts on the bottom of the workbench 1, the drive shaft of the servo motor 2 is parallel to the horizontal plane, and the drive shaft of the servo motor 2 is coaxially keyed and fixed with a mating block 3 , The end of the mating block 3 has a keyway mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com