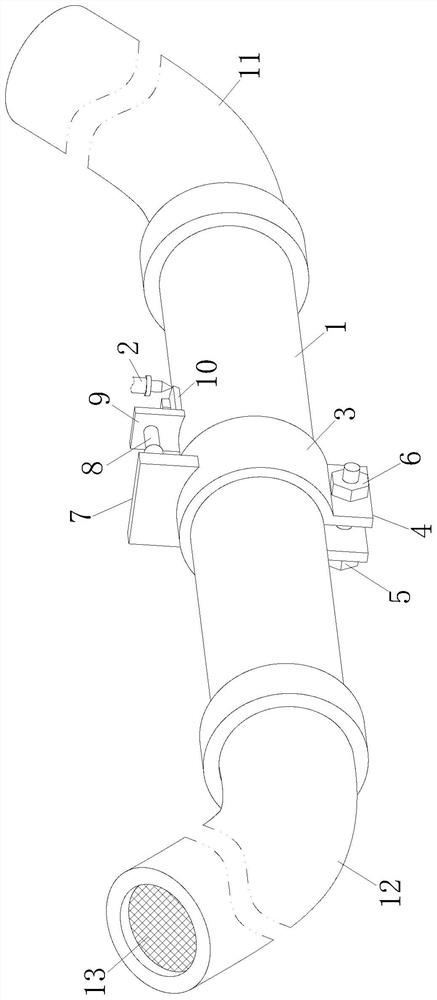

Perforating device for PVC pipeline

A punching device and pipeline technology, applied in the direction of pipe elements, pipes/pipe joints/pipes, separation methods, etc., can solve the problems of incomplete cooling, waste of water resources, debris easily falling inside the pipes, etc. Energy saving and practicality, the effect of reducing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

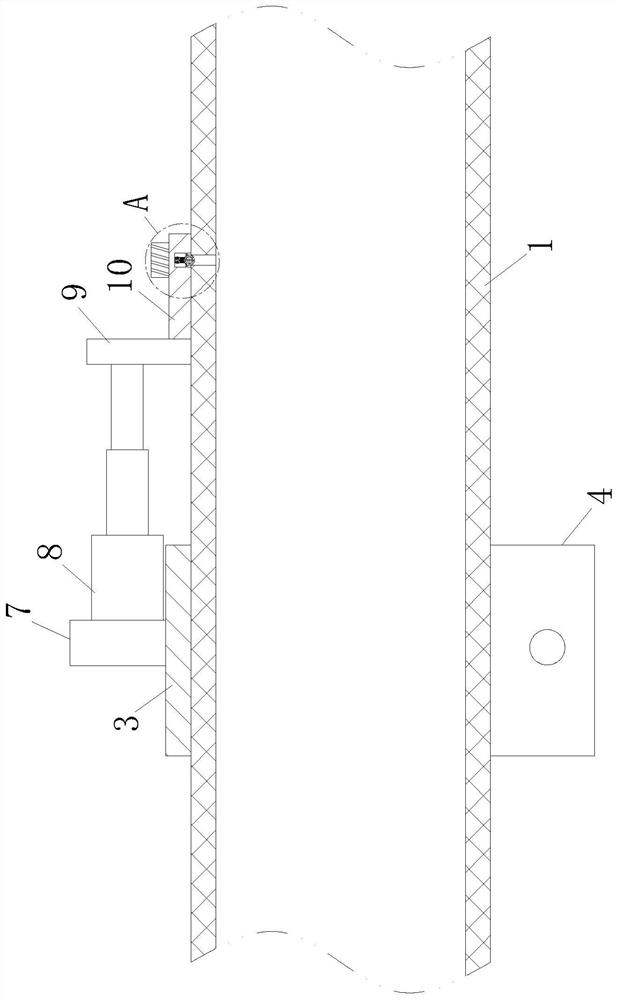

Method used

Image

Examples

Embodiment approach

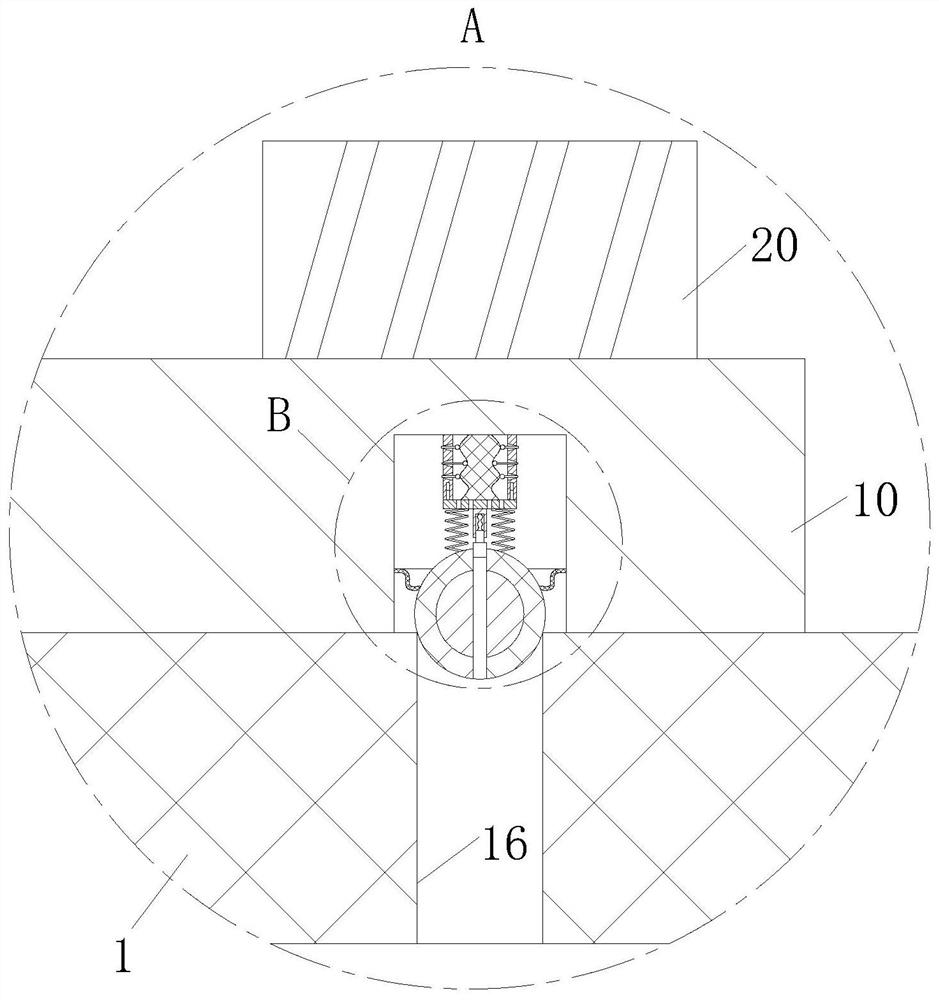

[0026] As an embodiment of the present invention, a chute 14 is opened on the side wall of the arc-shaped plate 10 close to the pipe body 1, and a spherical pressing block 15 is slidably connected to the outer end of the chute 14, and the pressing block 15 It can cooperate with the hole 16 punched by the drill bit 2 on the pipe body 1. The pressure block 15 is composed of an inner metal block 17 and an outer rubber layer 18. The pressure block 15 is connected to the inner end of the chute 14 There is a spring 19, and an electromagnet 20 capable of attracting the metal block 17 is installed on the side wall of the arc-shaped plate 10 away from the pipe body 1; during operation, before the arc-shaped plate 10 blocks the tunnel 16, at this time The pressure block 15 is pressed tightly on the side wall of the pipe body 1 under the action of the spring 19. When the arc plate 10 moves to the side of the channel 16, the chute 14 can synchronously drive the pressure block 15 to move to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com