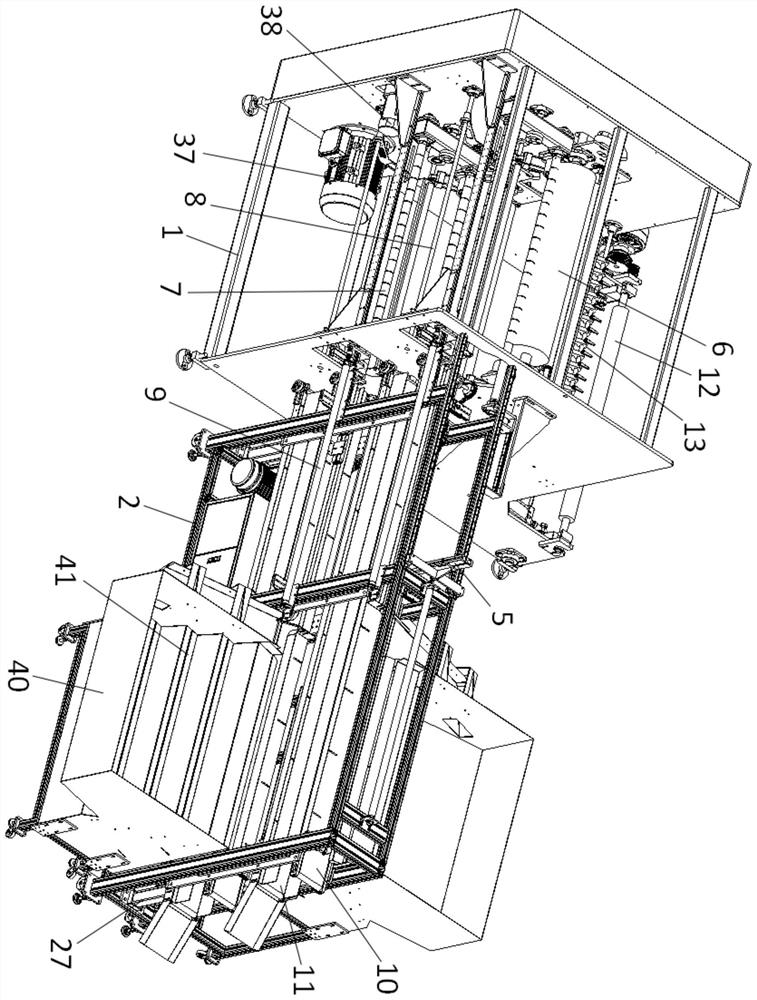

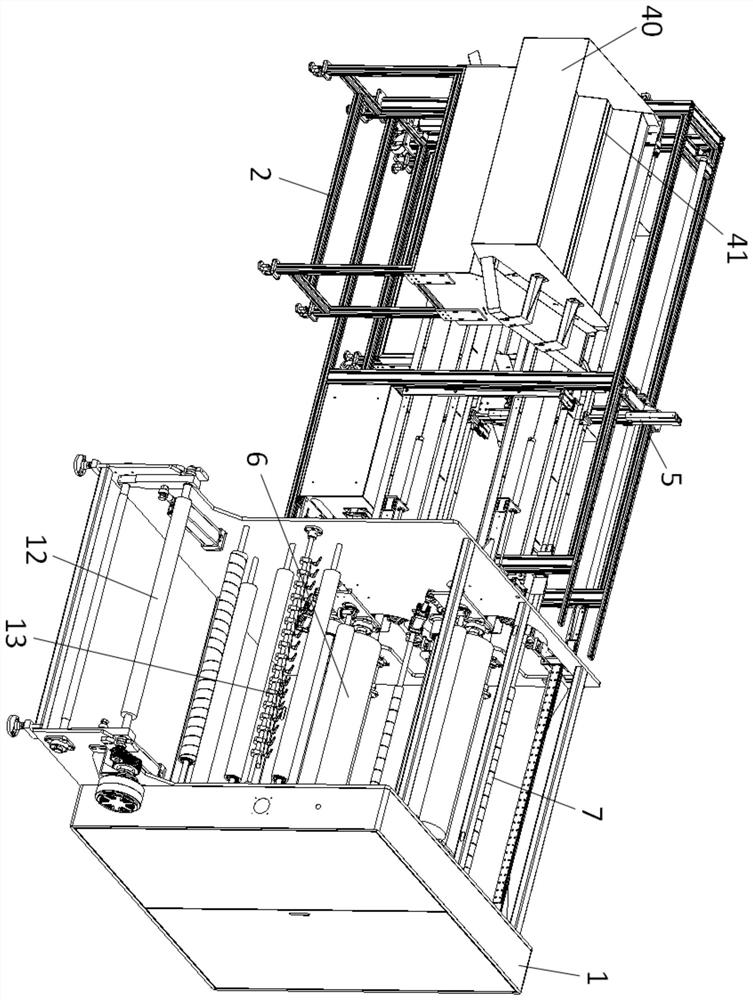

Automatic film cutting and rewinding machine

A cutting and rewinding machine, slitting and rewinding technology, applied in the field of automatic film slitting and rewinding machine, can solve the problems of poor work station structure cohesion, affecting production efficiency, low efficiency, etc., achieving a high degree of automation and practicality Strong, anti-static effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

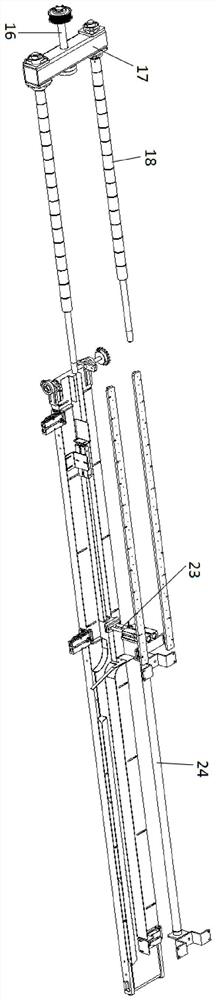

[0041] When in use, pipe materials of the same size are manually loaded into the upper pipe mechanism 40, and the pipe materials on both sides roll forward in the upper pipe mechanism 40 with the help of the inclined material plate 41, and the inner material plate 41 is placed on the upper pipe cylinder (not marked). ) under the control of rising, the internal pipe material is gradually delivered forward until it enters the feeding belt channel 10, and the clamping cylinder 36 pushes the rubberized shaft 15 to the driving shaft 14, and the feeding mechanism 5 pushes the cylinder 24 Promoting the feeding push plate 23 pushes the pipe material limited on the feeding belt passage 10 to the film-rewinding shaft 18 .

[0042] Manually load the film material onto the air shaft 30 and place it on the cantilever 28, the upper film cylinder 31 drives the cantilever 28 to rise to make the air shaft 30 rise to a specified height, and the film material on the air shaft 30 passes through th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com