A kind of water-steam shift reactor for autothermal reforming hydrogen production reaction and method for improving CO conversion rate of water-steam shift reaction

A water-vapor transformation and autothermal reforming technology, applied in chemical instruments and methods, hydrogen, inorganic chemistry, etc., can solve the problems of not considering waste heat utilization, high power consumption, unsuitable for large-scale industrial applications, etc., and achieve effective use of energy. , make full use of and improve the effect of hydrogen production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

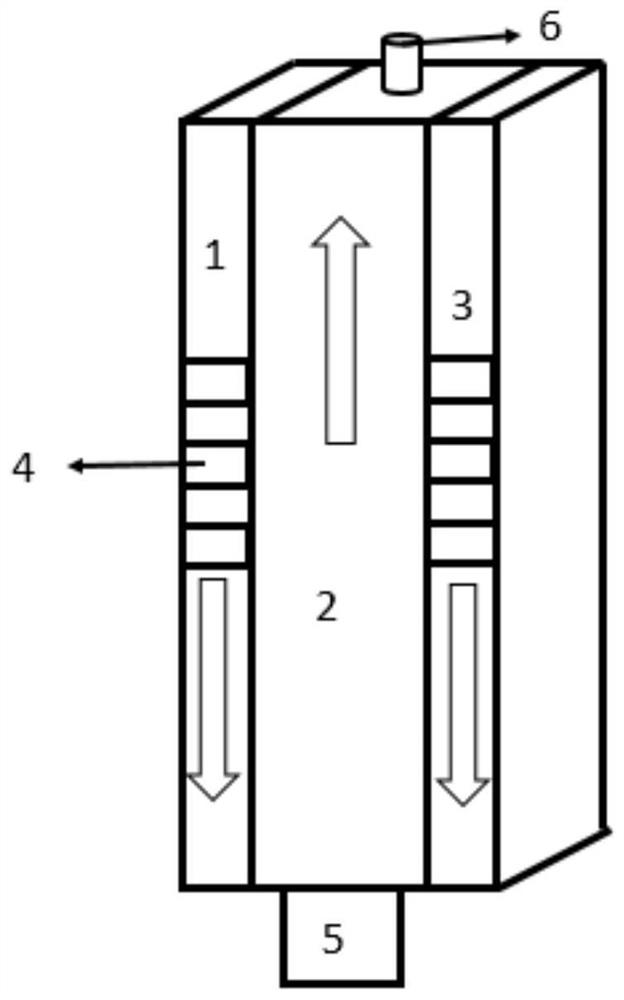

[0014] A water-steam shift reactor for autothermal reforming hydrogen production reaction, the reactor includes a square cavity, the two sides of the square cavity are water and air feed cavity and fuel feed cavity, the square cavity is on the upper Heat exchange fins are arranged on the sides of the cavity close to the water and air feed cavity and the fuel feed cavity to increase the heat exchange speed and form a temperature gradient; the lower end of the cavity is a high temperature inlet, and the upper end is a low temperature outlet. The heat exchange fins are perpendicular to the fluid flow direction in the square cavity and are located in the middle of the square cavity. The area of the heat exchange fins on each side of the square cavity is 1 / 2 or 1 of the side area of the square cavity. / 8.

[0015] The method for improving the CO conversion rate of the water-steam shift reaction by using the above-mentioned reactor, the square cavity of the water-steam shift rea...

Embodiment 2

[0019] After the fuel 15mL / min is completely burned, the tail gas will raise the temperature of the front-end reforming reactor and the shift reactor to about 700 ℃ and 500 ℃ respectively; then change the fuel 30mL / min, air 35L / min, deionized water feed 37mL / min , after being vaporized by the cavity water and air feed cavity and fuel feed cavity on both sides of the square cavity (the area occupied by the heat exchange fins on each side of the square cavity is 1 / 2 of the side area of the square cavity) Enter the reforming reactor to produce H after the reaction 2 and CO, the reactant gas enters the shift reaction chamber for the water-vapor shift reaction, and the CO is converted into H 2 ; The square cavity of the water-steam shift reactor is filled with catalysts, from bottom to top, 1 / 5 places are all high temperature shift catalysts; 2 / 5 to 4 / 5 places are a mixture of high temperature shift catalysts and low temperature change catalysts, and 2 / 5 places are high temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com