Process test method for pumping and pouring concrete in main arch pipe of concrete-filled steel tube arch bridge

A technology for concrete filled steel tubes and concrete pumps, which is applied in the construction of arch bridges, bridges, bridges, etc., and can solve problems such as easy blockage of pipes, lack of technical guidance for pumping construction, and bursting of pipes, and achieve the effect of ensuring the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The process test method for pumping and pouring concrete in the main arch tube of a CFST arch bridge according to the present invention comprises the following steps:

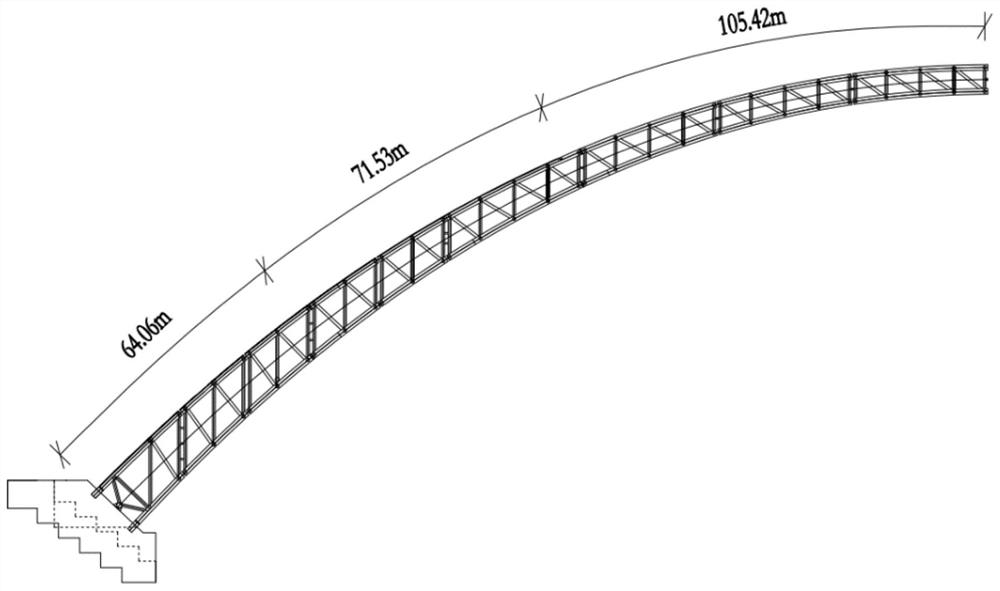

[0031] a. According to the design volume of concrete in the main arch pipe, the planned pumping section of the main arch is divided into three sections;

[0032] b. Obtain the first curve length and the second curve length in a manner of passing through the first-level segment and the second-level segment to the pouring port of the third-level segment, respectively, wherein the first curve length is from the first-level segment The arc length from the segment injection port to the second-level segment injection port, and the second curve length is the arc length from the second-level segment injection port to the third-level segment injection port;

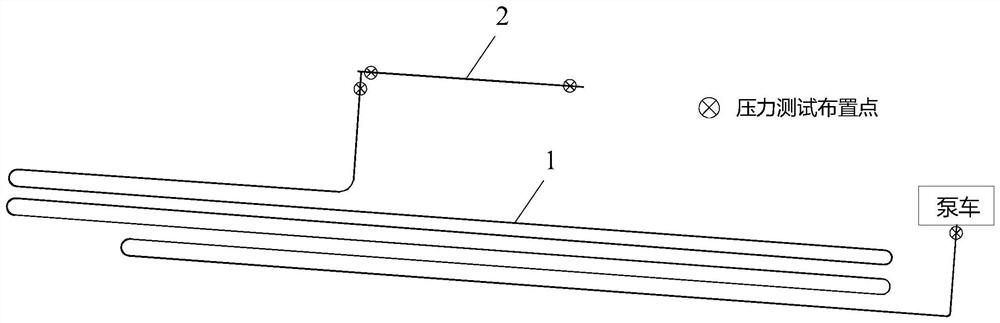

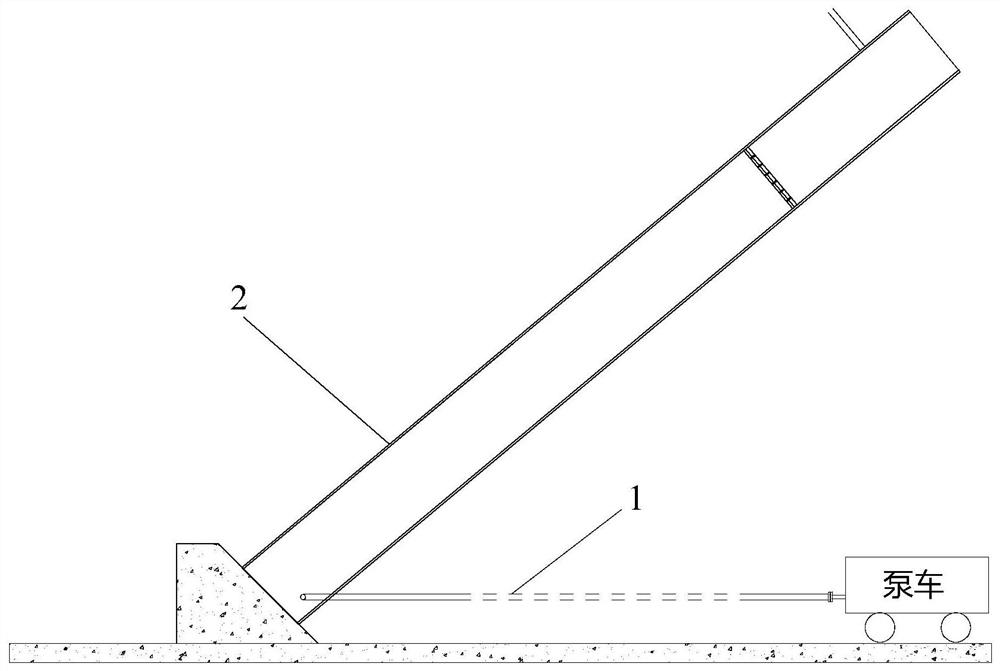

[0033] c. Convert the length of the first curve and the length of the second curve to the horizontal length of the test pump tube 1 under the same pumping p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com