Magnesium alloy safety helmet, magnesium alloy material, preparation method, preparation system and application

A magnesium alloy and equipment technology, applied in the field of magnesium alloy helmets, can solve the problems of poor protection performance, small impact load of helmets, inability to accurately detect magnesium alloy tensile strength data, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

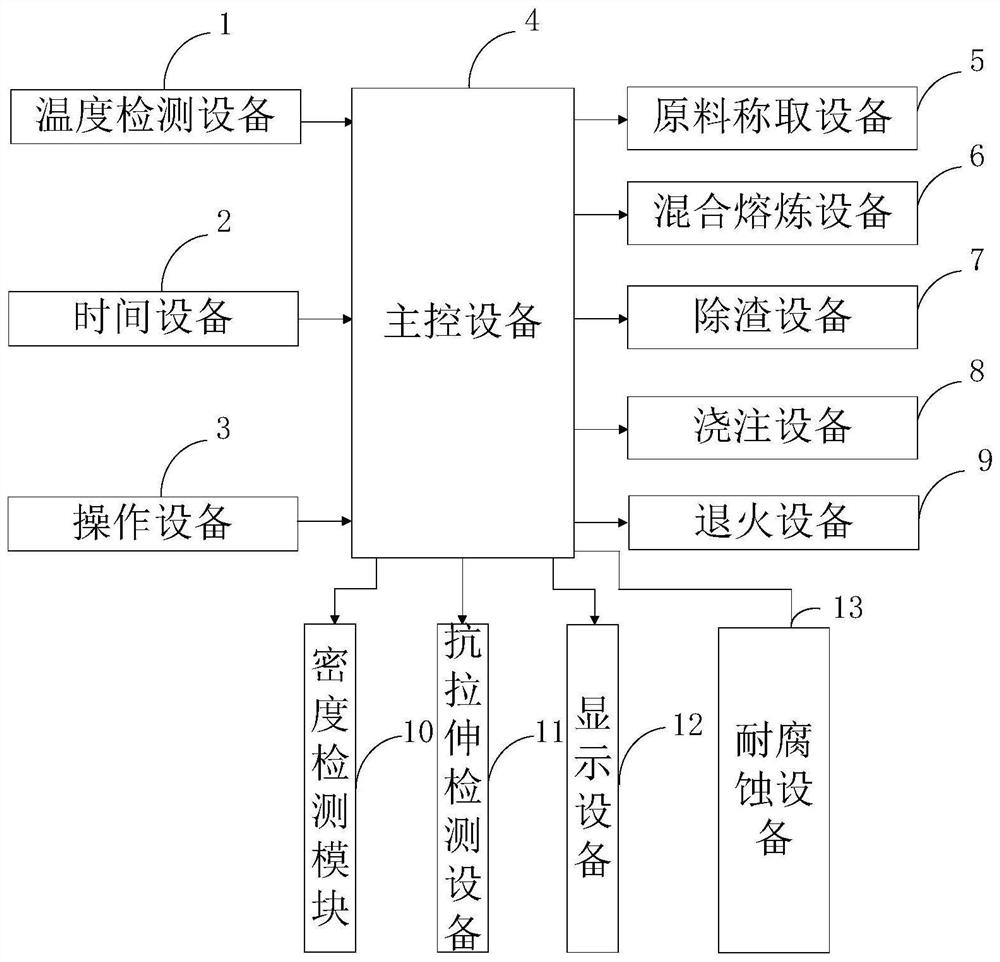

[0100] In order to further understand the content, features and effects of the present invention, the following examples are given, and detailed descriptions are given below with reference to the accompanying drawings.

[0101] The structure of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0102] The invention provides a magnesium alloy safety helmet, which is used in safety protection engineering. The magnesium alloy safety helmet is made of an improved magnesium alloy material instead of engineering plastics, and is cast by casting abrasives. The composition of the magnesium alloy material is composed of Mg 65%, Al 22%, Mn 3% and Zn 10% by mass percentage.

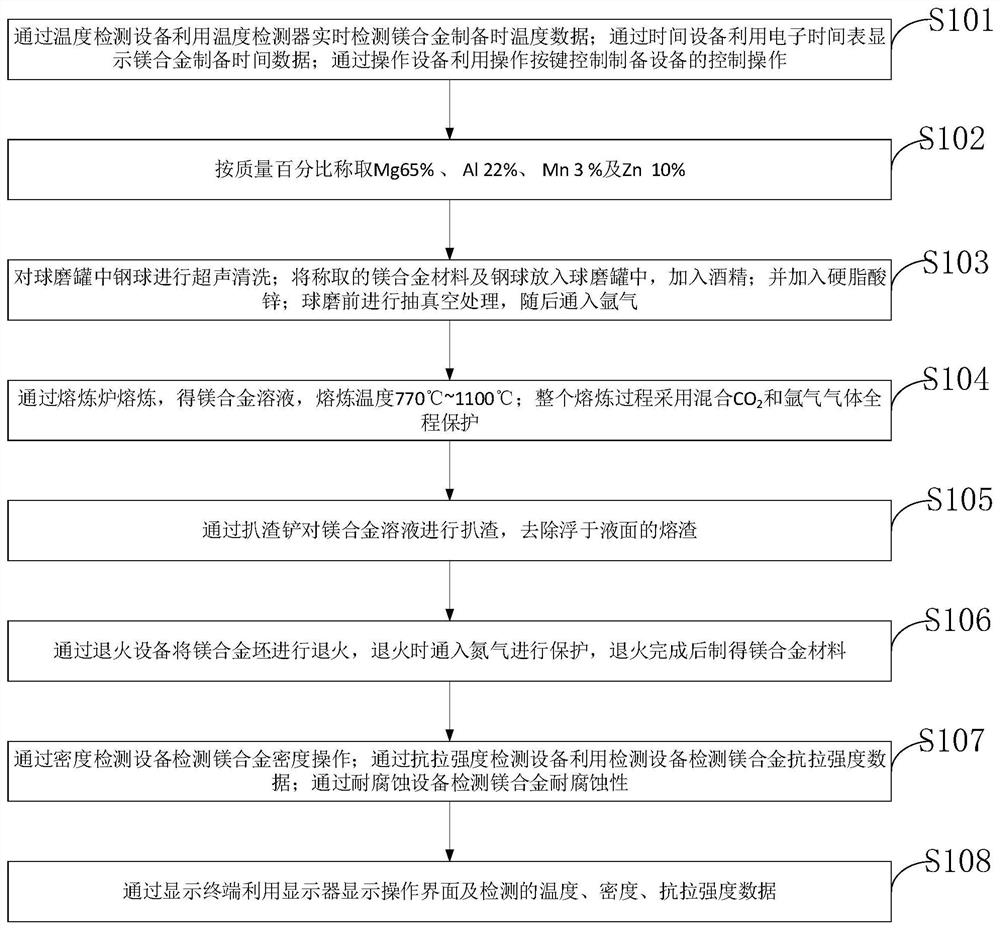

[0103] Such as Figure 9 Shown, the preparation technology of magnesium alloy material of the present invention comprises:

[0104] The first step is to use coal to produce semi-coke, tar and gas;

[0105] The second step is to use the produced semi-coke, sili...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com