Light guide plate and lattice point distribution method thereof

A light guide plate and dot technology, applied in light guides, optics, optical components, etc., can solve problems such as poor light output from the light guide plate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

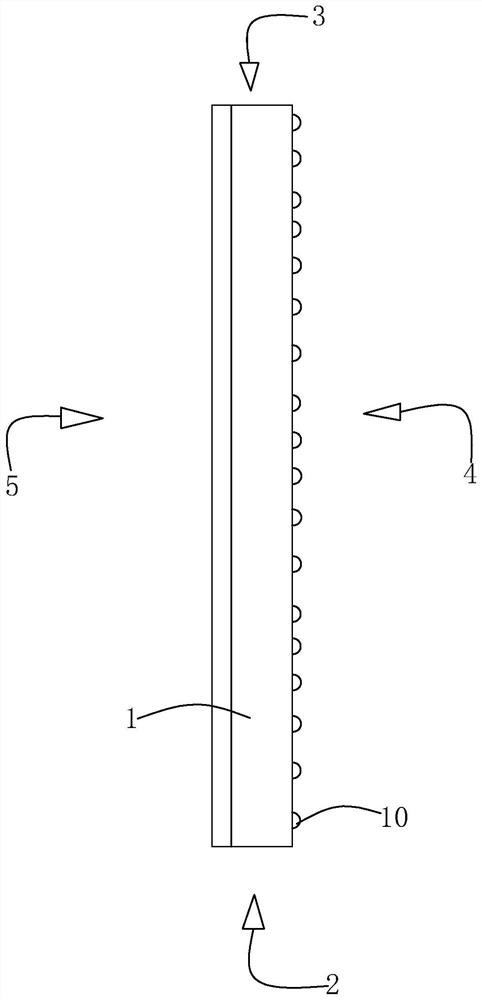

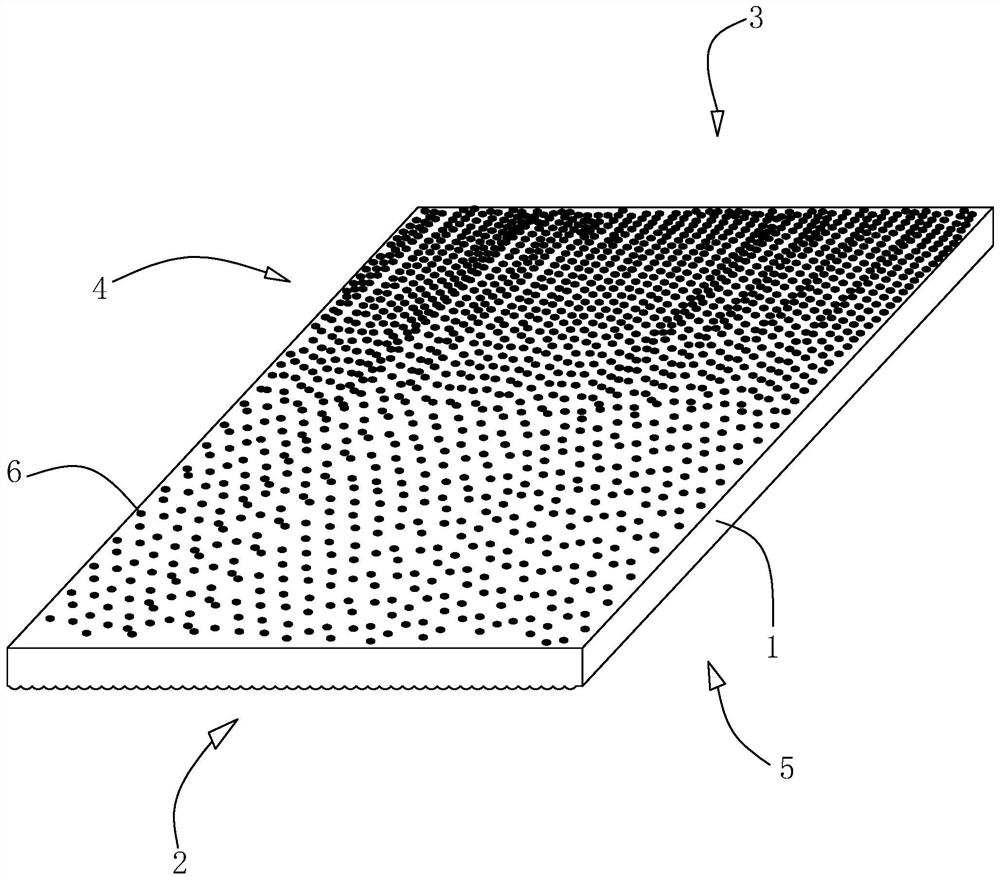

[0055] refer to figure 1 , a light guide plate, comprising a light guide plate body 1, the light guide plate body is made of PMMA material. The two ends of the length direction of the light guide plate body 1 are the light incident side 2 and the light exit side 3 respectively, the light incident side 2 is the incident direction of the light source, and the two sides in the thickness direction of the light guide plate body 1 are the reflective surface 4 and the light exit surface 5 respectively. , wherein the light emitting surface 5 is the effective viewing area of the light guide plate body 1 .

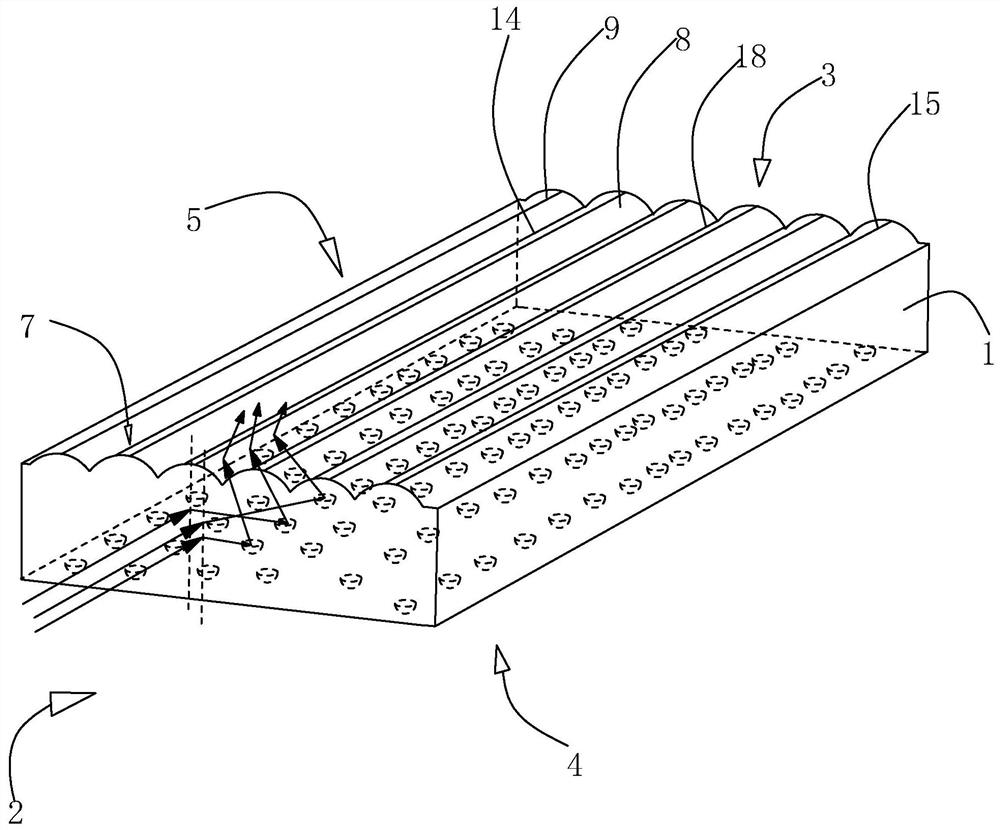

[0056] refer to figure 2 The light emitting surface 5 of the light guide plate body 1 is provided with a light emitting groove 7, the light emitting groove 7 is arranged along the length direction of the light guide plate body 1 and is consistent with the incident direction of the light source, and the depth of the light emitting groove 7 must be greater than or equal to 3um. I...

Embodiment 2

[0065] Embodiment 2: refer to Figure 5 , and the difference from Example 1 is that the reflective surface 4 is provided with a reflective groove 10, the reflective groove 10 is arranged along the length direction of the light guide plate body 1 and is consistent with the incident direction of the light source, and the depth of the reflective groove 10 is less than or equal to 4um . In this embodiment, multiple reflective slots 10 may be provided, and the multiple reflective slots 10 are arranged sequentially along the width direction of the light guide plate, so that the reflective surface 4 forms multiple reflective curved surfaces 11 that reflect or scatter light from the light source.

[0066] A plurality of reflective curved surfaces 11 are arranged sequentially along the length direction of the light guide plate body 1 . The opposite sides of two adjacent reflective curved surfaces 11 can be superimposed and connected to form a third coincident side 16 and a fourth coin...

Embodiment 3

[0070] Embodiment 3: refer to Figure 7 , different from Embodiment 1, the two sides in the length direction of the first curved surface 8 and the second curved surface 9 are respectively the first curve 12 and the second curve 13, the radius of curvature of the first curve 12 and the radius of curvature of the second curve 13 The radius of curvature is small, and the radius of curvature of the first curve 12 and the radius of curvature of the second curve 13 are both within 0-25um. Therefore, the radius of curvature of the first curved surface 8 and the second curved surface 9 gradually increases from the light incident side 2 to the light exit side 3 along the length direction of the light guide plate, so that the light receiving surface of the first curved surface 8 and the second curved surface 9 can be along The length direction of the light guide plate body gradually increases, so that the light source light is more refracted as the light source light is closer to the li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com