Additive manufacturing self-supporting structure topological optimization method suitable for variable critical angle

A self-supporting structure, topology optimization technology, applied in design optimization/simulation, special data processing applications, instruments, etc., can solve problems such as the need for support, and achieve the effect of optimal design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

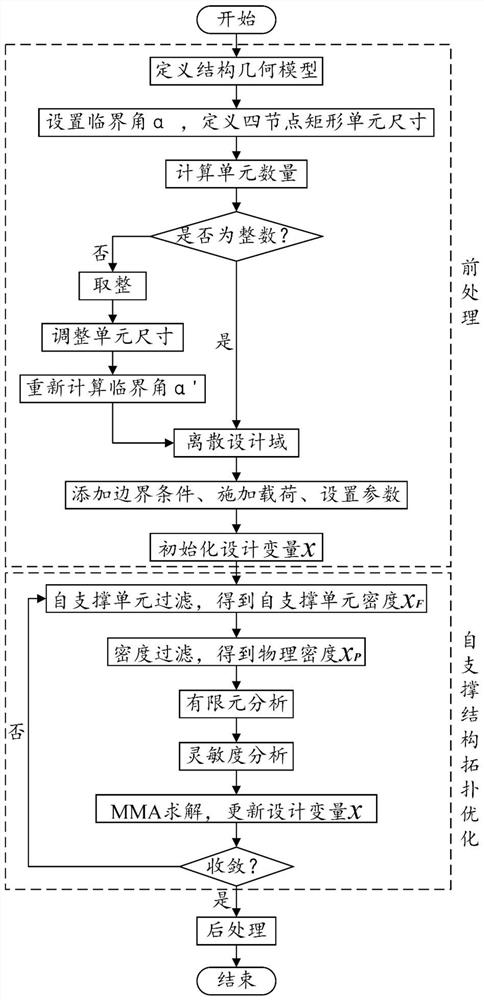

[0042] The method proposed by the present invention can be used for the plane problem of self-supporting structure design oriented to additive manufacturing. The following describes the specific implementation process of the present invention in conjunction with the case and accompanying drawings. figure 1 A flow diagram of the invention is shown.

[0043] (1) Pretreatment

[0044] The specific steps are as follows:

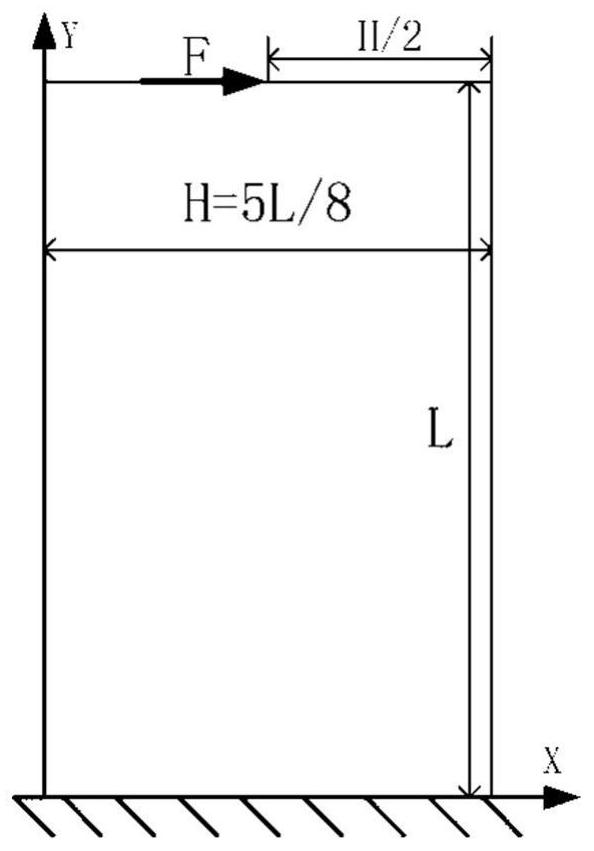

[0045]1) Define the geometric model of the cantilever beam, such as figure 2 As shown, the cantilever beam structure is optimally designed along the +Y direction, taking L=160, H=100 as an example for calculation and description;

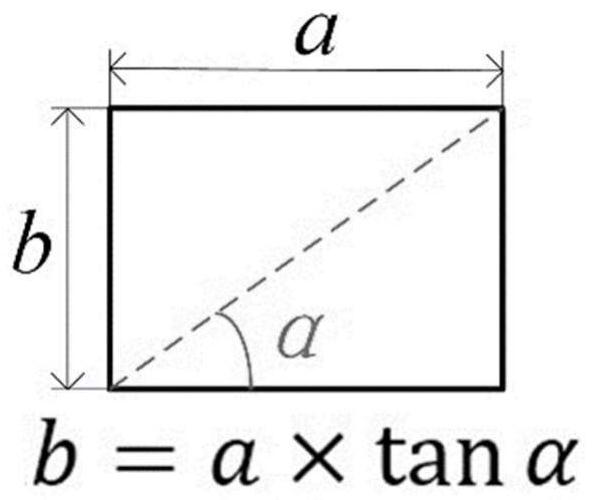

[0046] 2) Set the critical angle α, define the length and width of the four-node rectangular element as a and b respectively, and satisfy b=a×tan α, such as image 3 As shown, take α=30°, a=1, b=tan 30° as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com