Railway wagon cab apron falling fault identification method

A railway freight car and fault identification technology, applied in neural learning methods, character and pattern recognition, instruments, etc., can solve the problems of railway freight car ferry plate falling off, fault detection accuracy and low efficiency, and achieve edge integrity and self-adaptation High, accurate results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

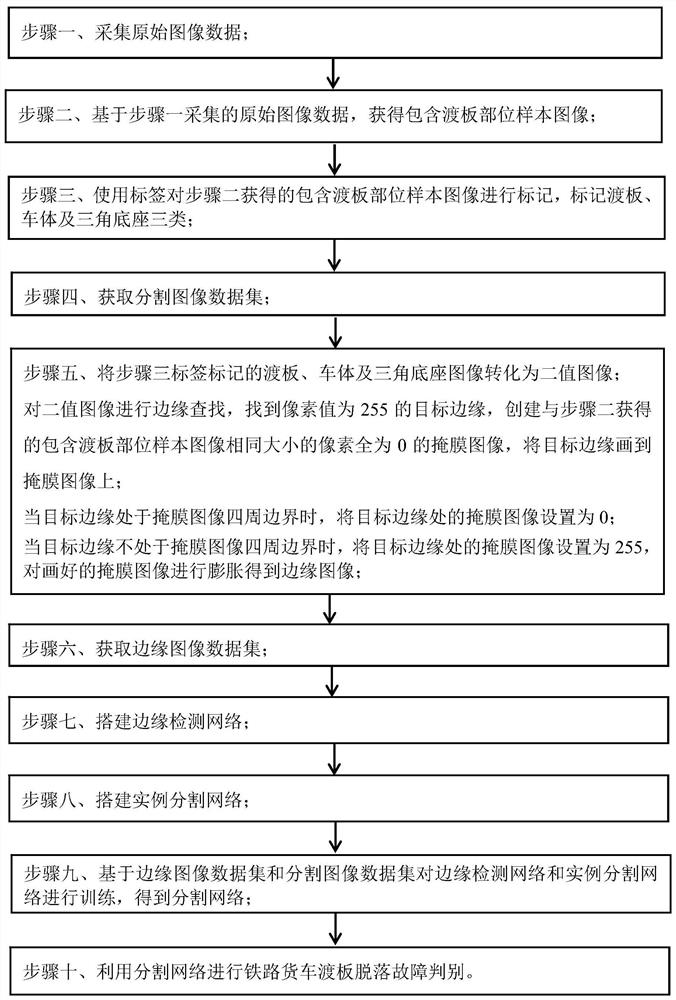

[0072] Specific implementation mode one: combine figure 1 Describe this embodiment, the specific process of a kind of fault identification method that the ferry plate of railway wagon falls off in this embodiment is:

[0073] Step 1, collecting original image data;

[0074] Step 2, based on the original image data collected in step 1, obtain a sample image including the part of the transition plate;

[0075] Step 3. Use tags to mark the sample image including the transition plate part obtained in step 2, and mark the three types of transition plate, car body and triangular base;

[0076] Since the angle of the camera at different stations and the distance between the camera and the car body will be different, a fixed part is required for pixel calibration; the position and posture of the ferry board are easy to change, but the position of the triangular base supporting the ferry board is fixed and cannot be moved. Therefore, in order to unify the fault standard, mark the tri...

specific Embodiment approach 2

[0089] Specific embodiment two: the difference between this embodiment and specific embodiment one is that the original image data is collected in step one; the specific process is:

[0090] Set up high-speed imaging equipment at a fixed detection site to obtain 2D high-definition linear array grayscale images of trucks, and select images taken by the camera above the side of the truck (used at the same time on the left and right) as the original image; long-term image collection, to obtain images taken at different sites and under different conditions For the original image, different conditions refer to images with various natural disturbances such as light, rain, etc. in the image to ensure the diversity of the data, so that the final model will have better robustness.

[0091] Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0092] Specific embodiment 3: The difference between this embodiment and specific embodiment 1 or 2 is that in step 2, based on the original image data collected in step 1, a sample image including the transition plate is obtained; the specific process is:

[0093] According to the prior knowledge and the wheelbase information provided by the hardware and framework (data acquisition equipment such as sensors), the original image is intercepted to obtain a sample image including the transition plate.

[0094] Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com