Aluminum alloy smelting automatic feeding tower and automatic feeding method thereof

An aluminum alloy, melting furnace technology, applied in chemical instruments and methods, cleaning methods and utensils, cleaning methods using liquids, etc. Avoid clogging of valve ports, improve the problem of poor combustion efficiency, and have the effect of strong use reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

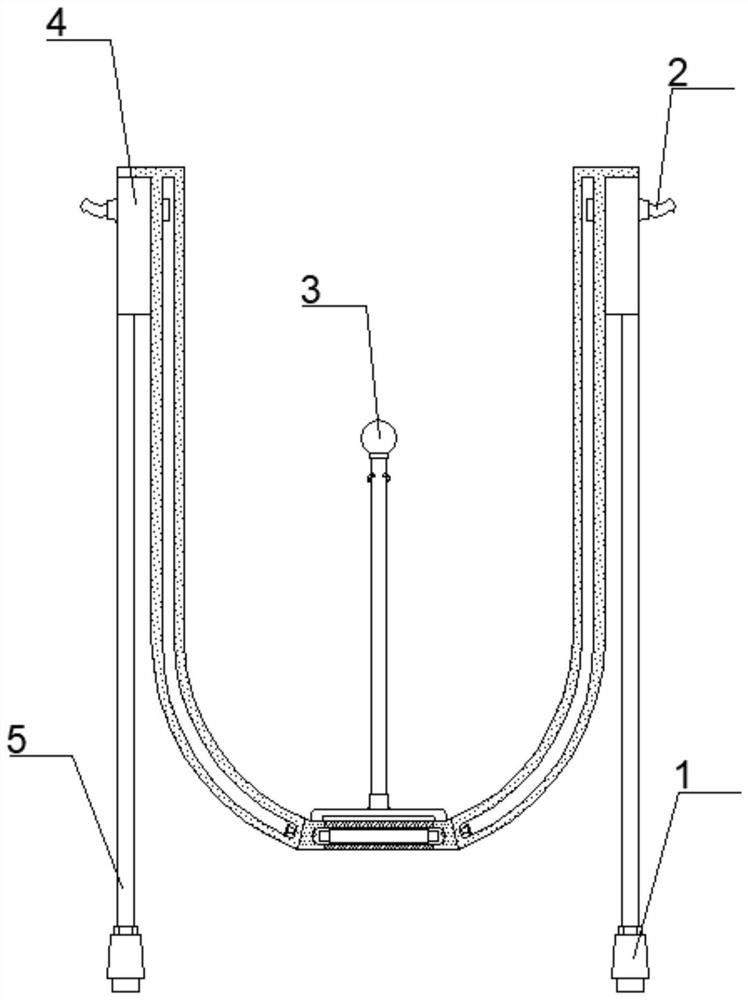

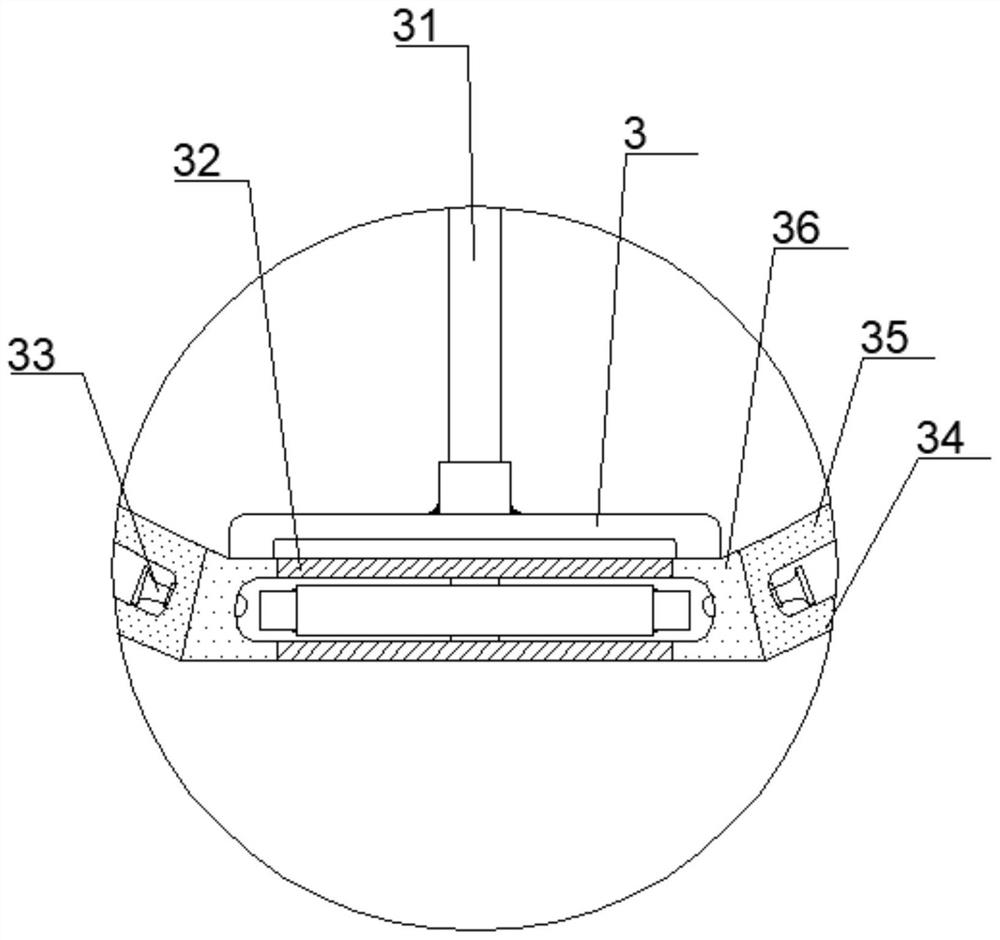

[0035] like Figure 1-2As shown, the aluminum alloy smelting automatic feeding tower includes a feeding assembly 3 and an evaporating assembly 4. The evaporating assembly 4 is fixedly connected to both sides of the feeding assembly 3. The outer wall of the evaporating assembly 4 is embedded with a sleeve, and the sleeve is socketed. There are water pipes 2; two supporting pipes 5 are symmetrically fixed at the bottom of the evaporation assembly 4, and the bottom of the supporting pipes 5 is fixedly connected with a smoke guide pipe 1, and the smoke guide pipe 1 is plugged and fixed to the top wall of the melting furnace; the feeding assembly 3 includes Vibrating part 31, valve part 32, nozzle 33, outer barrel 34, inner barrel 35 and air guide seat 36, inner barrel 35 is set in the outer barrel 34, the upper and lower annular edges of inner barrel 35 and outer barrel 34 are fixedly connected; inner barrel 35 and An air guide seat 36 is sleeved on the connected lower annular edg...

Embodiment 2

[0039] like Figure 2-7 As shown in the automatic feeding tower for aluminum alloy smelting, the valve member 32 includes an upper circular plate 321, a spacer bar 322, a blocking unit 323, a lower circular plate 324 and a reset unit 325, and an upper circular plate 321 and a lower circular plate 321 are arranged in the air guide seat 36. Plate 324, the surface of upper circular plate 321 and lower circular plate 324 are all run through and be provided with semicircle slot position; The upper circular edge is connected, and the outer edge of the lower circular plate 324 is connected with the lower circular edge of the air guiding seat 36; a barrier unit 323 is arranged between the upper circular plate 321 and the lower circular plate 324, and the barrier unit 323 is covered with a spacer bar 322 , the upper and lower ends of the spacer bar 322 are fixedly connected to the center of the upper circular plate 321 and the lower circular plate 324; one side of the spacer bar 322 is...

Embodiment 3

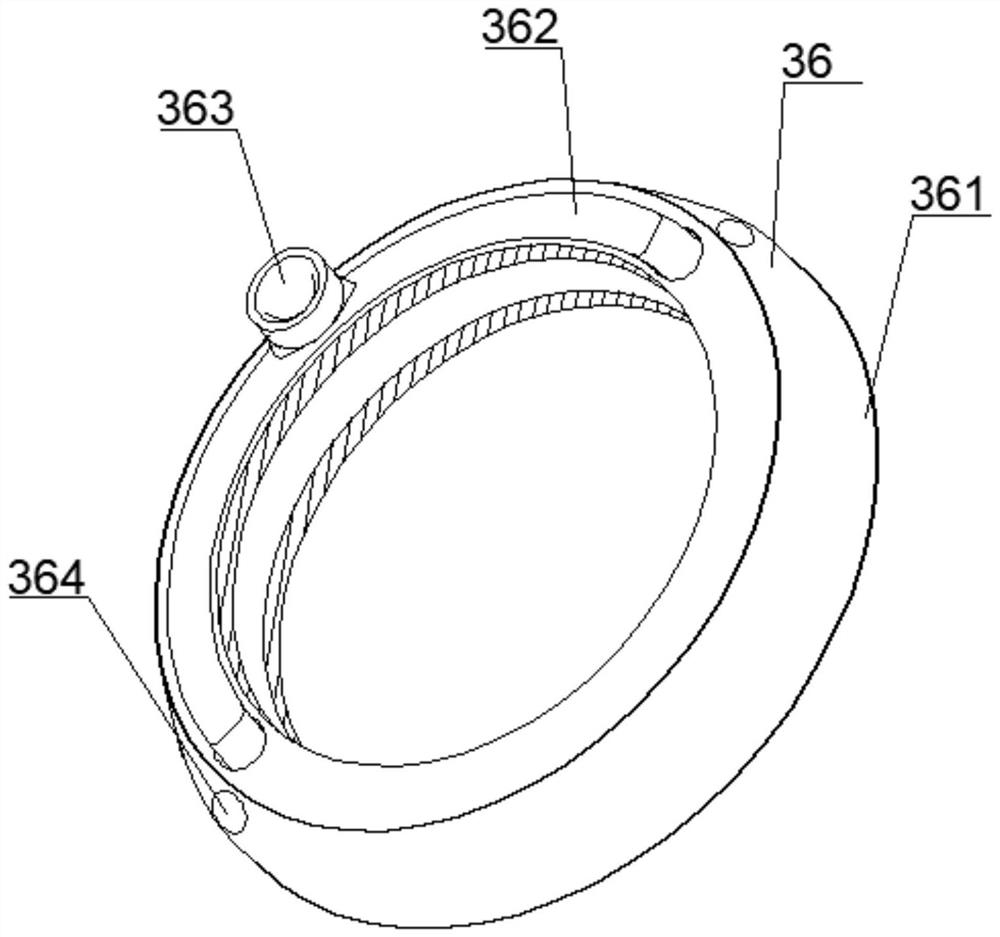

[0045] like figure 1 , 2 , 7 and 8, in the aluminum alloy smelting automatic feeding tower, the air guide seat 36 includes a double-layer ring seat 361, a half-ring pipe 362, a pipe seat 363 and a socket 364, and the lower annular edge of the inner barrel 35 and the outer barrel 34 A double-layer ring seat 361 is sleeved, and the two sides of the double-layer ring seat 361 are provided with a jack 364, and the nozzle 33 is set inside the jack 364; The two ends of the tube are fixedly connected with vertical tubes, and the vertical tubes are inserted into the double-layer ring seat 361; the top side of the half-ring tube 362 is connected with a tube seat 363, and the vibrating member 31 is sleeved and fixed in the tube seat 363.

[0046] The vibrating element 31 includes a sphere 311, a row pipe 312, an elbow nozzle 313 and a firing unit 314. The row pipe 312 is plugged and fixed to the air guide seat 36. A sphere 311 is arranged inside the row pipe 312. The diameter of the sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com