Water spraying control system of automobile water spraying windscreen wiper

A technology of a control system and a body controller is applied in the field of water spray wipers for automobiles, and can solve problems such as affecting the control reliability of a washer pump and the cleaning effect of water spray wipers and shortening the service life of water spray wipers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

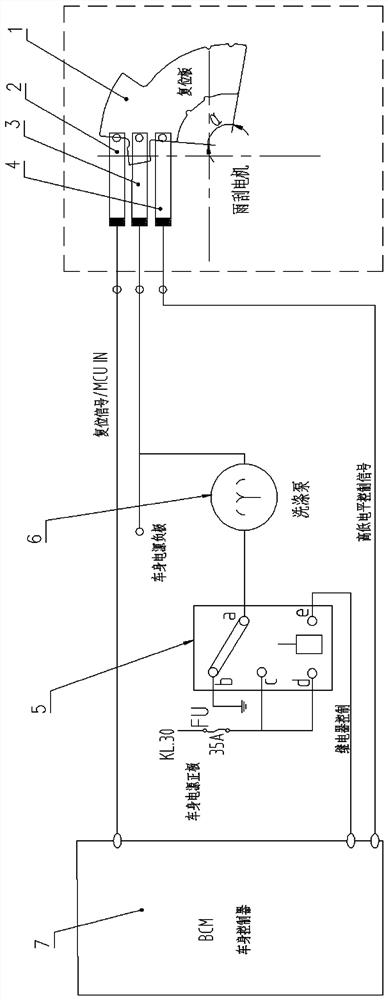

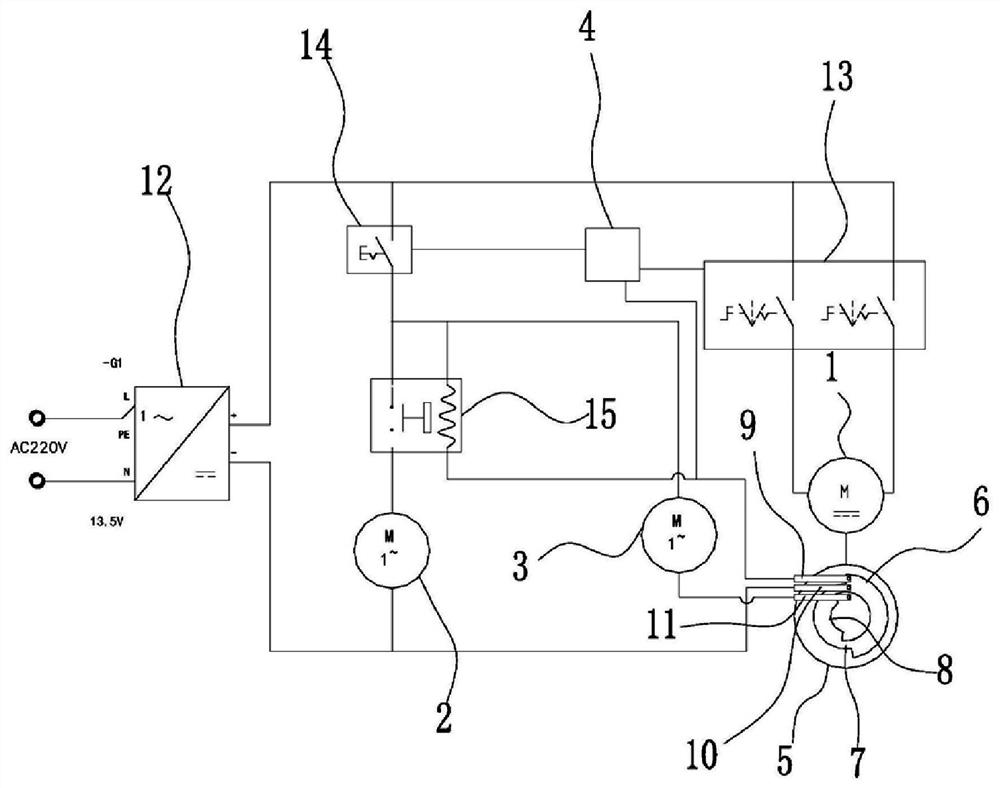

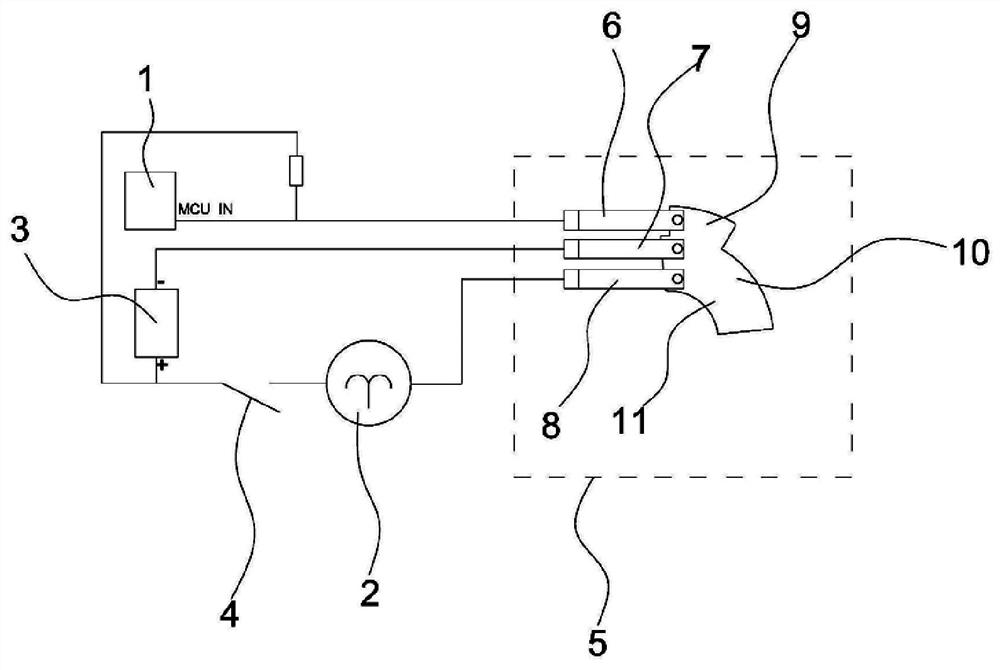

[0015] see figure 1 , a water spray control system for automobile water spray wipers, comprising a wiper motor, a washing pump 6, a first contact 2, a second contact 3, and a third contact 4, the motor shaft of the wiper motor The insulating disk is fixed circumferentially, and a conductive plate 1 is arranged on the insulating disk. The conductive plate 1 is in the shape of a circular arc concentric with the insulating disk. The central angle of the conductive plate 1 is less than or equal to 180°. When the wiper motor is running, The motor shaft will drive the insulating disc and the conductive plate 1 to rotate together. The front end of the conductive plate 1 is in contact with the first contact 2, the second contact 3, and the third contact 4, and these three contacts are all located at the front end of the conductive plate 1 in the direction of rotation, so that the conductive plate 1 rotates 360° Afterwards, the three contacts can contact with the front end of the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com