A dust-absorbing insulation structure for a distribution box

A technology of insulating structure and distribution box, applied in substation/distribution device casing, electrical components, circuit devices, etc., can solve problems such as affecting the working quality and service life of electronic devices, increasing labor intensity of workers, and troublesome unpacking and cleaning. , to achieve the effect of improving the efficiency of dust removal, strong practicability and market competitiveness, and low cost of transformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

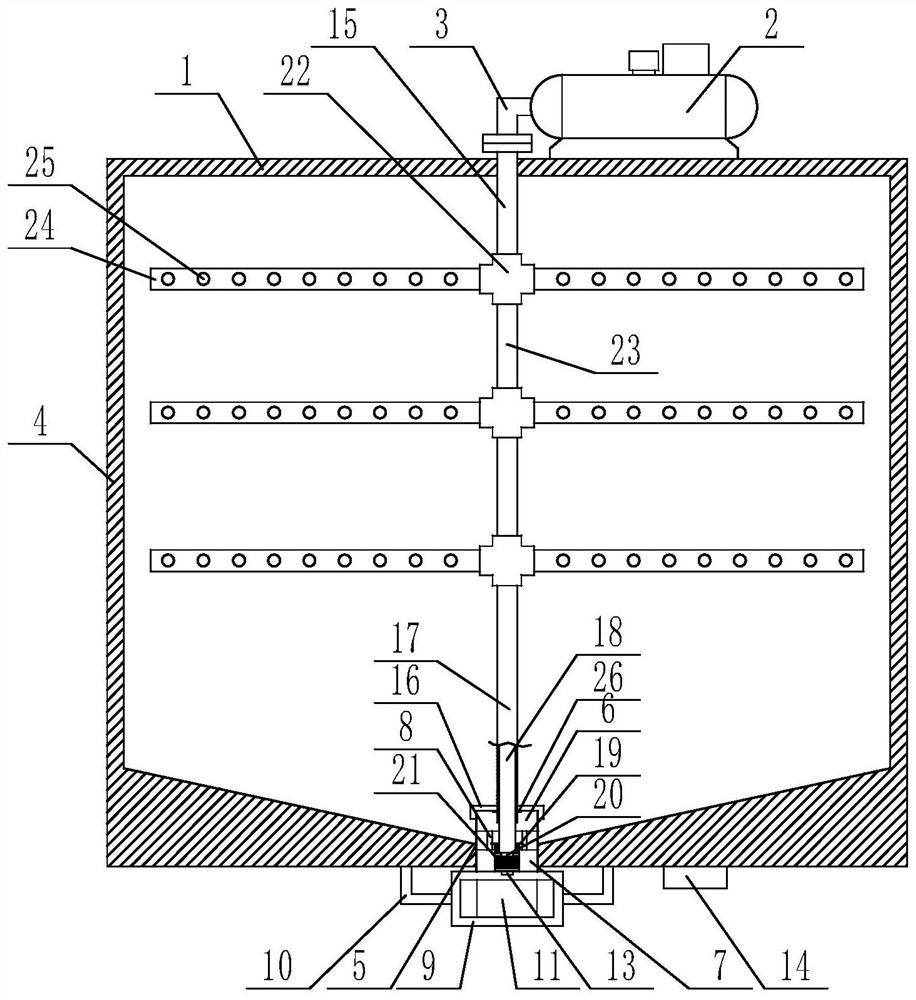

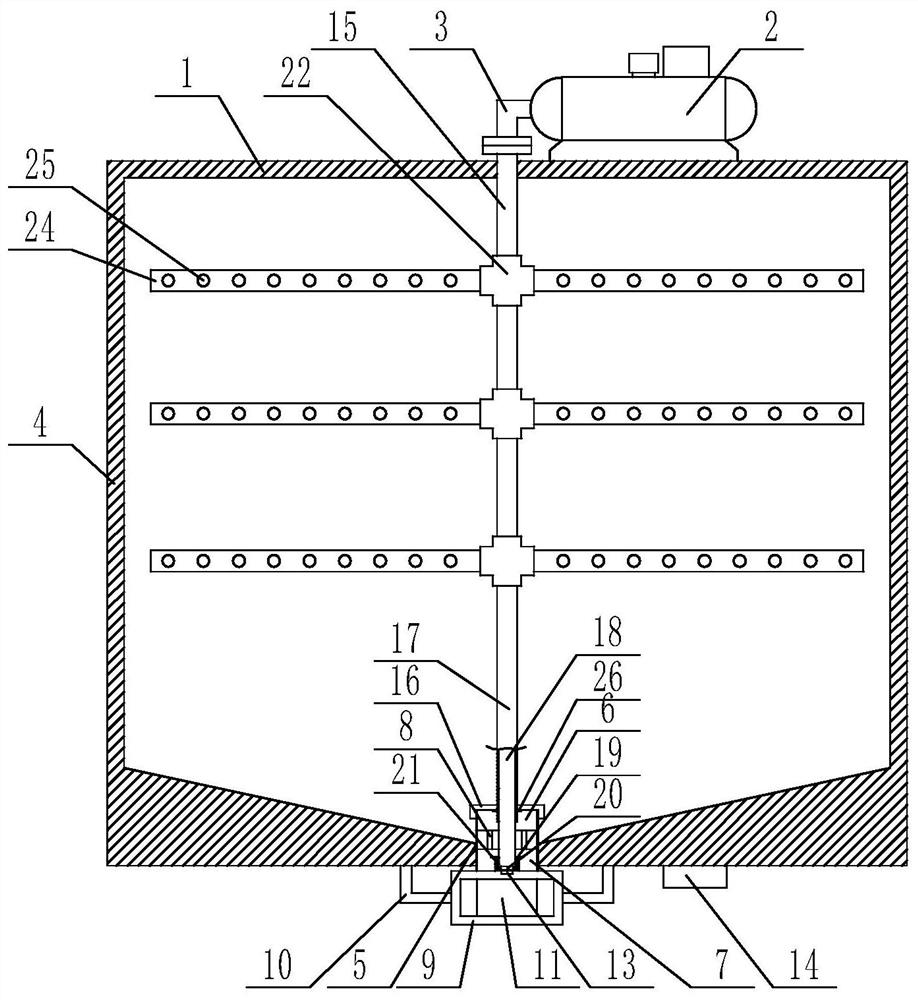

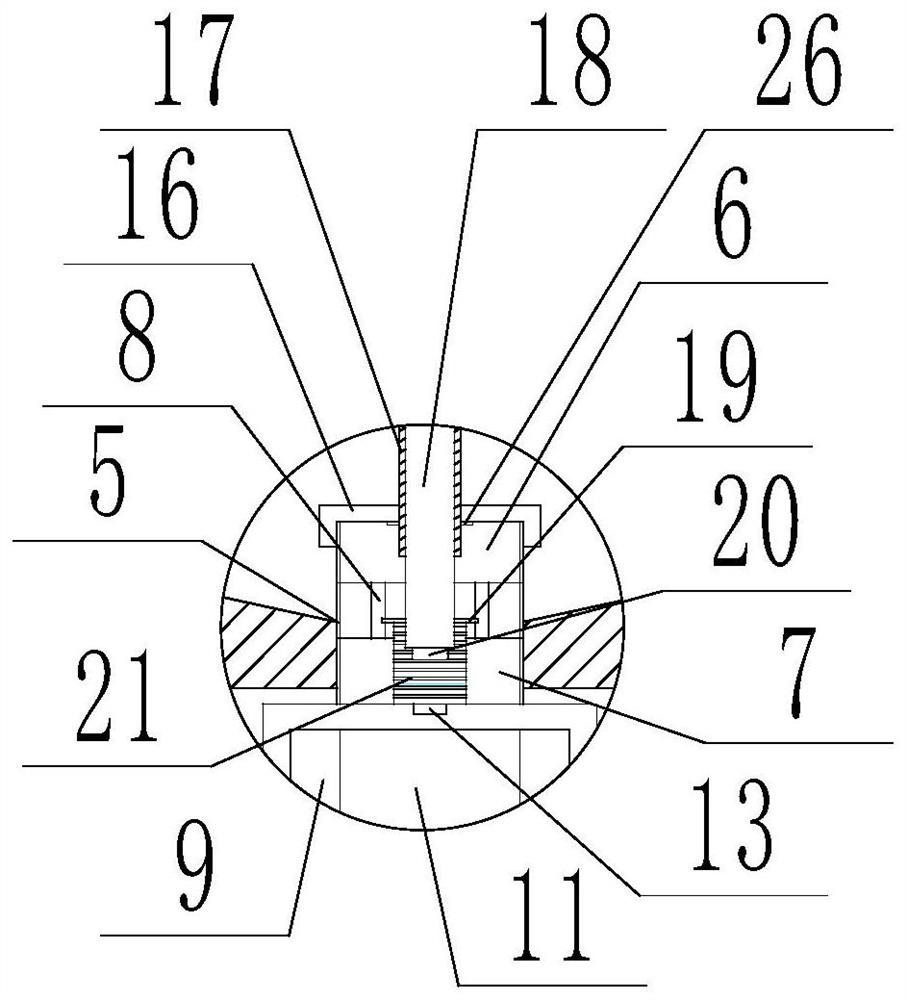

[0045] During the implementation of the technical solution of the present application, the initial state of the device is as follows figure 1 As shown, at this time, the pneumatic rod is in the rising state under the action of the spring, the magnet is far away from the Hall switch, the Hall switch is disconnected, and the fan does not work when the power is off; The controller starts the electric air pump, at this time the electric air pump pumps high-pressure air into the air intake pipe through the L-shaped pipe, the high-pressure air enters the connecting pipe and the exhaust pipe through the four-way pipe, and the high-pressure air is blown in through several air holes in the exhaust pipe The distribution box blows up the dust in the distribution box, and the blown dust finally falls on the bottom surface of the insulating inner shell and slides along the bottom surface to the vicinity of the suction pipe. At the same time, the high-pressure airflow enters the next four T...

Embodiment 2

[0047] The magnet on the lower end face of the pneumatic rod is removed, and the Hall switch is replaced by a button switch or a pressure switch, and the others are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com