A rapid evaluation method for the applicability of tobacco flavor raw materials in cigarette production process

A production process and technology for tobacco, which is applied in the field of rapid evaluation of the applicability of tobacco flavor raw materials in the cigarette production process, can solve the problems of lack of methods for distinguishing the thermal stability of flavor raw materials, and achieve a good effect of flavor enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The tobacco aroma raw material selected in this example is citric acid.

[0036] Tobacco incense raw materials, water, and propylene glycol were analyzed and detected by thermogravimetric analysis according to the following conditions: sample amount: 10-80 mg; purge gas: N 2 Or compressed air; purge gas flow: 90mL / min; equilibrium gas flow: 10mL / min; heating program: 10°C / min speed, from room temperature (25-30°C) to 400°C.

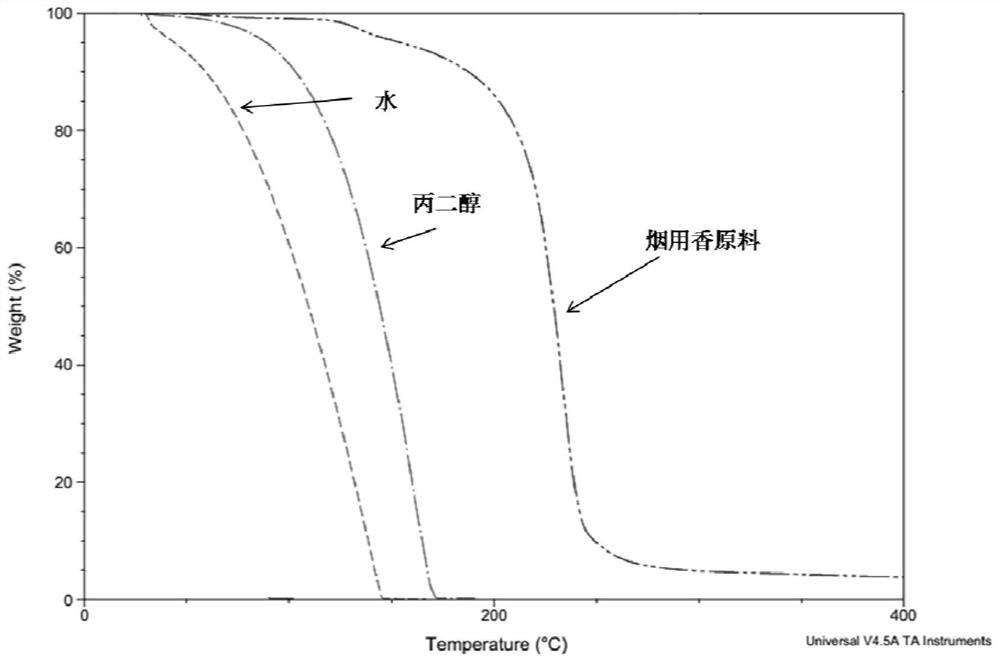

[0037] The thermogravimetric curve analysis diagram is as follows figure 1 shown.

[0038] It can be clearly seen from the figure that the weight change curve of the tobacco incense raw material is located on the right side of propylene glycol, indicating that the tobacco incense raw material has better thermal stability at higher temperatures, and the tobacco incense raw material is suitable for cigarettes Feeding link in the production process.

Embodiment 2

[0040] The tobacco incense raw material selected in this embodiment is ethyl propionate.

[0041] Tobacco incense raw materials, water, and propylene glycol were analyzed and detected by thermogravimetric analysis according to the following conditions: sample amount: 10-80 mg; purge gas: N 2 Or compressed air; purge gas flow: 90mL / min; equilibrium gas flow: 10mL / min; heating program: 10°C / min speed, from room temperature (25-30°C) to 200°C.

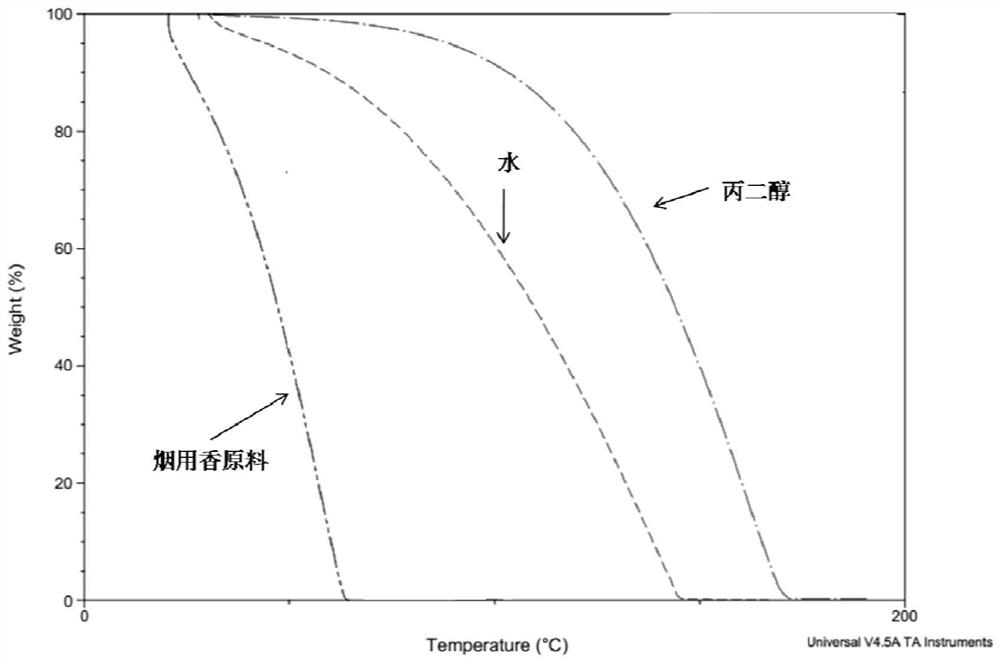

[0042] The thermogravimetric curve analysis diagram is as follows figure 2 shown.

[0043] It can be clearly seen from the figure that the weight change curve of the tobacco incense raw material is located on the left side of the ethanol, indicating that the thermal stability of the tobacco incense raw material is poor, and the tobacco incense raw material is suitable for addition in the cigarette production process. Fragrance link.

Embodiment 3

[0045] The tobacco incense raw material selected in this example is Peruvian extract, which is denoted as incense raw material 3.

[0046] Tobacco incense raw materials, water, and propylene glycol were analyzed and detected by thermogravimetric analysis according to the following conditions: sample amount: 10-80 mg; purge gas: N 2 Or compressed air; purge gas flow: 90mL / min; equilibrium gas flow: 10mL / min; heating program: 10°C / min speed, from room temperature (25-30°C) to 400°C.

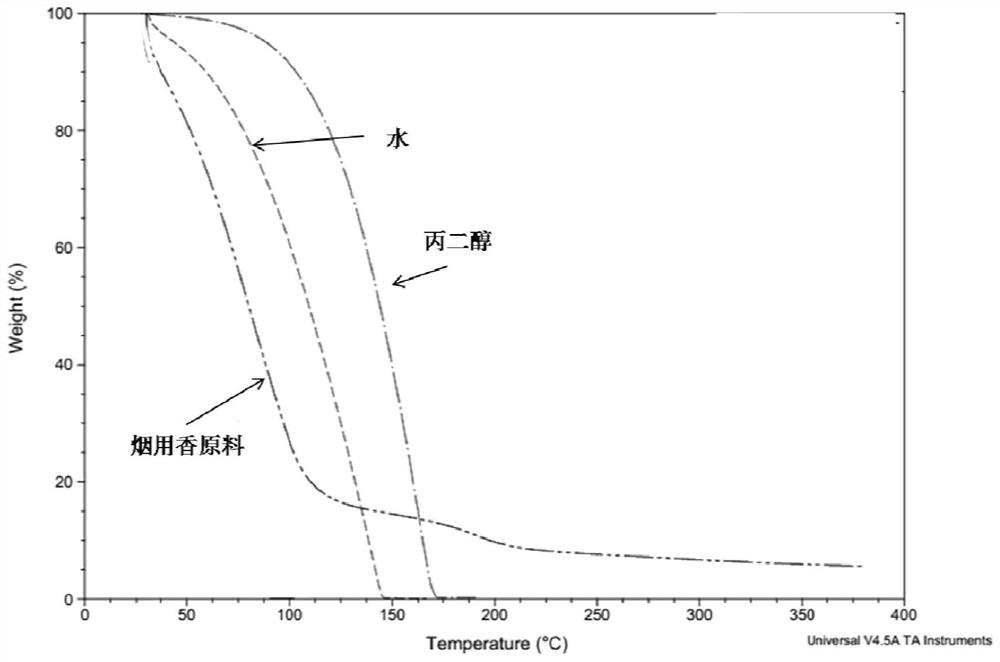

[0047] The thermogravimetric curve analysis diagram is as follows image 3 shown.

[0048] It can be clearly seen from the figure that the weight change curve of the tobacco incense raw material is between water and propylene glycol. It is further judged that the weight loss rate of the tobacco incense raw material at 150°C reaches 85wt%, which indicates that the tobacco incense raw material has a The thermal stability is poor. According to the evaluation method of the present invention, the weig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com