A kind of purposes of sophorolipid

A technology of sophorolipid and lactone-type sophorolipid, which is applied in the field of tobacco moisturizing processing, can solve the problems of less moisturizing agent and the like, and achieve the effects of low price, simple addition process and simple preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Embodiment 1: preparation

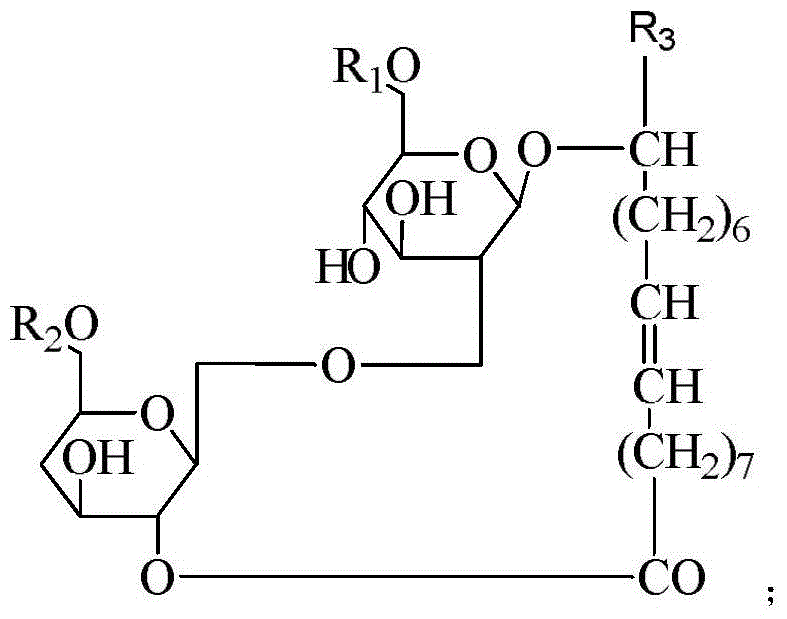

[0038] The obtained sophorolipid is obtained by fermenting and culturing Wickerhamiella domercqiae for 5 days at 30° C. and 220 rpm. Wherein the fermentation medium consists of: glucose 6wt%, Na2HPO 4 12H 2 O 0.1wt%, MgSO 4 ·7H 2 O0.05wt%, KH 2 PO 4 0.1wt%, oleic acid 6wt%, yeast powder 0.3wt%; then the fermentation broth was extracted with twice the volume of ethyl acetate, and the upper organic phase was distilled under reduced pressure at 50°C and washed twice with n-hexane, then decompressed at 50°C pressure distillation to obtain a light yellow blocky solid, which is the lactone-type sophorolipid; the lower aqueous phase is vortex mixed with twice the volume of ethanol, centrifuged to take the supernatant, washed twice with n-hexane after vacuum distillation, and then washed for 50 °C and dried under reduced pressure to obtain a dark brown viscous liquid, which is the acid type sophorolipid.

Embodiment 2

[0039] Example 2: Application

[0040] 1. Moisture-proof and moisture-proof experiment

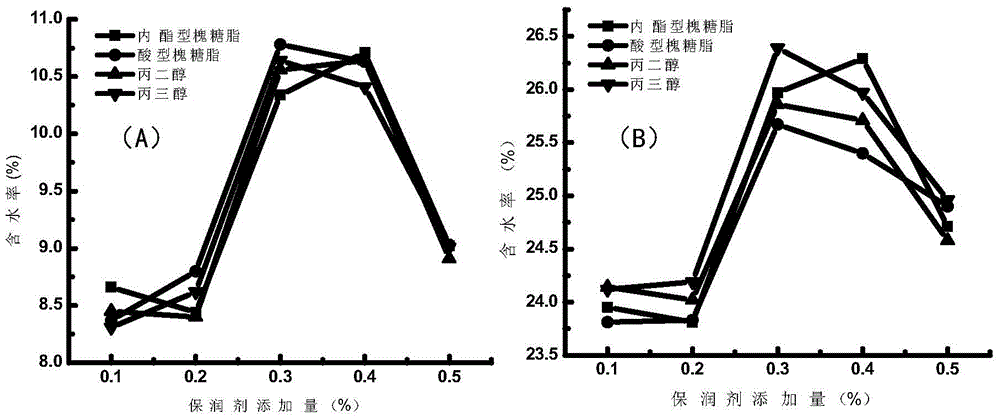

[0041] The lactone-type sophorolipid and the acid-type sophorolipid prepared in Example 1 were added to shredded tobacco at a ratio of 0.1% by mass of shredded tobacco, and shredded tobacco samples added with equal amounts of propylene glycol and glycerin were used as controls. Then, divide the treated cut tobacco samples into two parts, place them in constant temperature and humidity chambers at 22°C, RH 40% and 22°C, RH 80%, and weigh them once at regular intervals to measure the water content of the cut tobacco within 48 hours. rate changes. Taking time as the abscissa and the moisture content of the sample as the ordinate, draw the moisture content curve of the sample over time. The final moisture content is shown in Table 1 and figure 1 .

[0042]Increase the amount of lactone-type sophorolipids and acid-type sophorolipids to 0.2%, 0.3%, 0.4%, and 0.5%, and keep other operations un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com