Pipeline filter screen disassembly-free cleaning method and device

A pipeline and filter technology, applied in the field of non-dismantling cleaning, can solve the problems of not always having working tools, heavy maintenance workload, high cost, etc., and achieve the effects of simple and convenient cleaning and maintenance, long system life and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] 1. Method, structure and connection

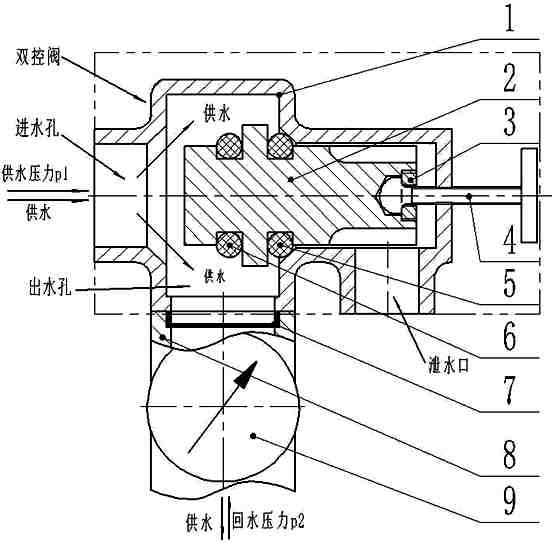

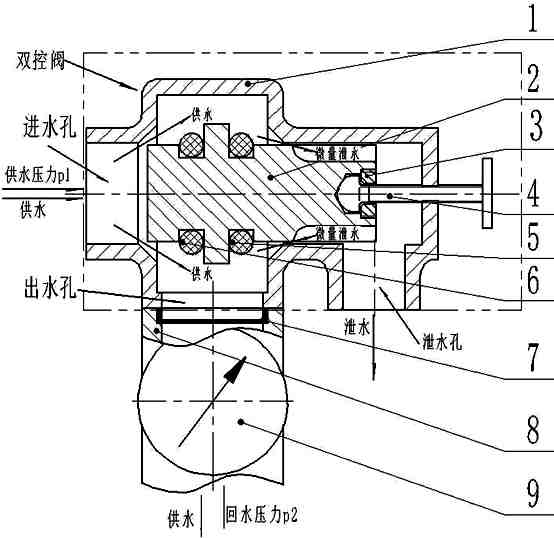

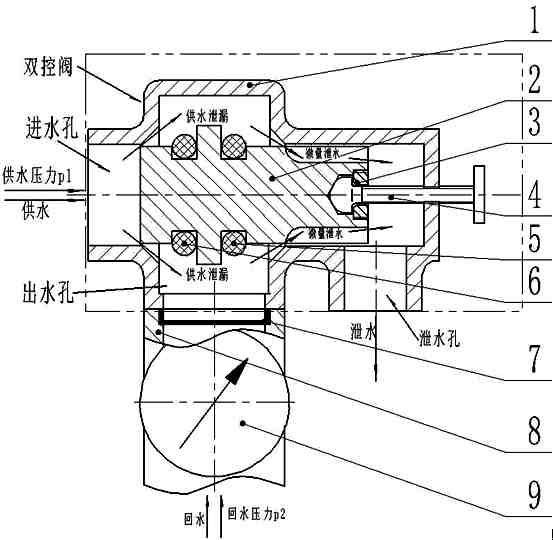

[0020] 1. Specific methods: such as figure 1 As shown, the present invention utilizes the characteristic that the return water of the system pipeline has a certain pressure, and installs a double control valve between the water inlet control valve of the pipeline branch (for general conventional technology, not shown in the figure) and the pipeline filter screen 7, The closing and opening of the water inlet and the water discharge are synchronously controlled by the double control valve, and the pipeline filter screen 7 (in the water branch pipeline 8 before the meter 9) is installed to reversely flush the backwater to block and absorb the sundries and pass through the drain hole. After the pipeline system is discharged, the double control valve will simultaneously open the water inlet hole and close the water discharge hole to restore the normal operation of the pipeline system.

[0021] 2. The specific structure and connection of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com