A viscous medium preparation device and a viscous medium preparation method

A viscous medium and preparation device technology, applied in the direction of mixing methods, chemical instruments and methods, transportation and packaging, etc., can solve the problems of limited range of options and inability to meet the forming requirements of parts, and achieve stable pressure values and simple structures , easy-to-operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

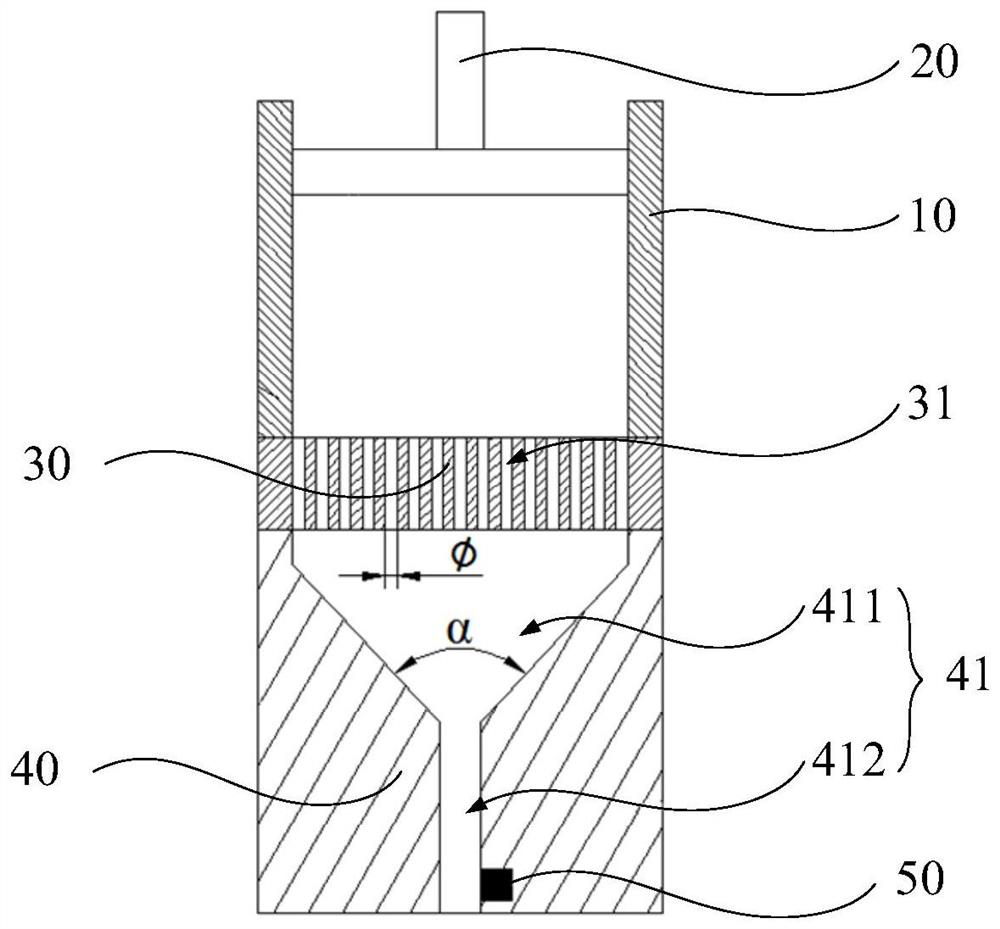

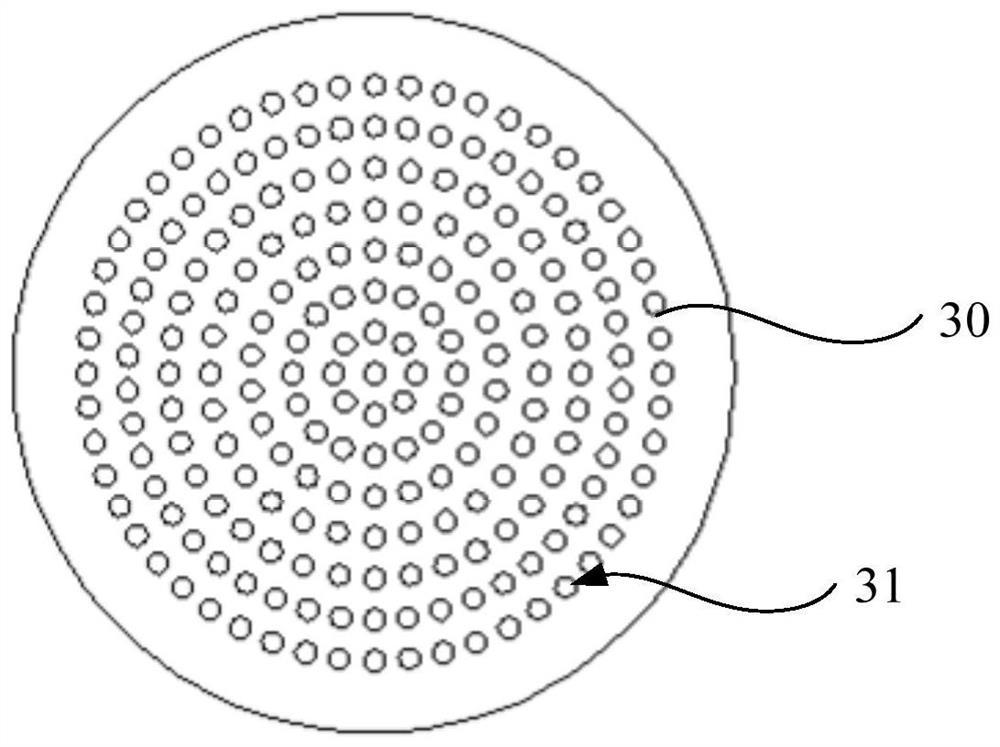

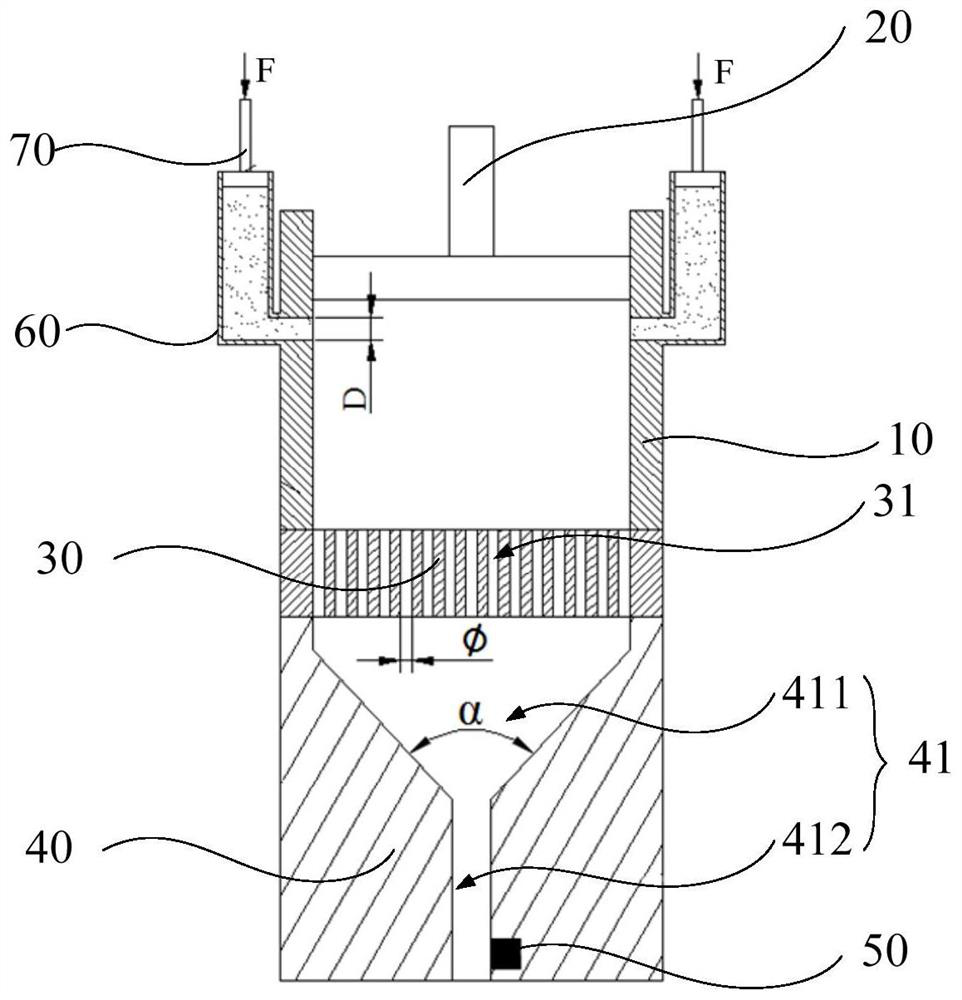

Embodiment 1

[0060] Such as Figure 6 to Figure 8 As shown, six injection channels 60 are arranged on the medium bin 10, and three kinds of viscous mediums 80 with molecular weights of 100kg / mol, 300kg / mol, and 900kg / mol are selected and loaded into six respectively according to the ratio of 4:5:1. Injection channels 60, that is, every two injection channels 60 inject viscous medium 80 of the same molecular weight, start the pressure rods 70 in the six injection channels, and inject viscous medium 80 into the medium chamber 10, during the process of injecting viscous medium 80 , the multiple sub-holes 61 of the injection port change the viscous medium 80 gathered into a group in the injection channel 60 into filaments and inject it into the medium chamber 10, so that the contact area between viscous media 80 of different molecular weights is increased, so that various molecular weights The viscous medium 80 in the medium bin 10 is initially mixed; after the viscous medium 80 is injected in...

Embodiment 2

[0062] Such as Figure 6 to Figure 8 As shown, three injection channels 60 are arranged on the medium bin 10, and three viscous mediums 80 with molecular weights of 200kg / mol, 700kg / mol, and 800kg / mol are selected and loaded into three respectively according to the ratio of 3:3:4. Injection channels 60, start the pressure rods 70 in the three injection channels, inject the viscous medium 80 into the medium chamber 10, during the process of injecting the viscous medium 80, the multiple sub-holes 61 of the injection port will gather the injection channels 60 into one The viscous medium 80 of agglomerate becomes filiform injection in the medium storehouse 10, makes the contact area increase between the viscous medium 80 of different molecular weights, thereby makes the viscous medium 80 of various molecular weights initially mix in the medium storehouse 10; To the medium storehouse 10 After injecting the viscous medium 80, the viscous medium 80 in the medium chamber 10 is pressed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com