Robot feeding and stamping production line for household appliance box

A robot and production line technology, applied in the field of sheet metal stamping production line, can solve the problems of low degree of automation, dangerous working environment, low production efficiency, etc., and achieve the effect of high production safety, high safety and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

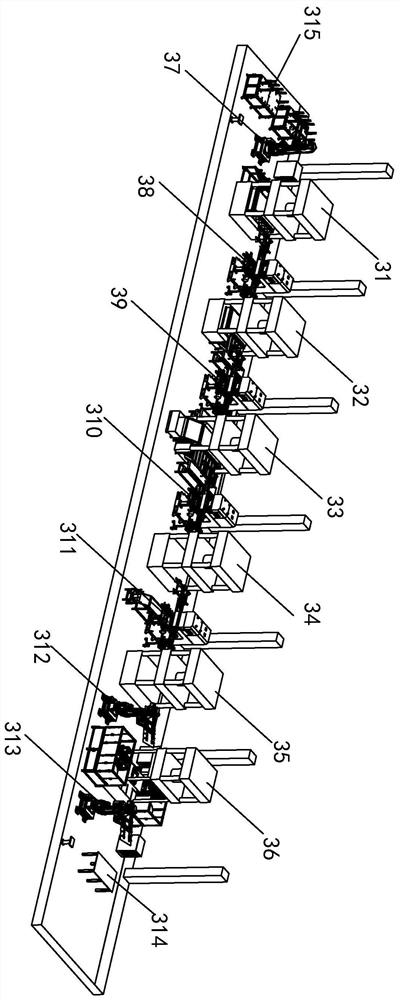

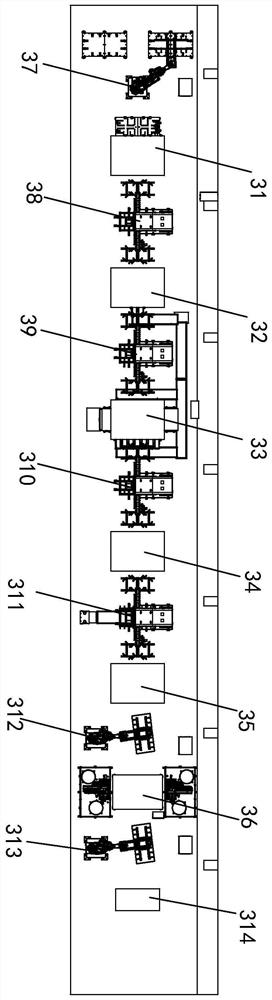

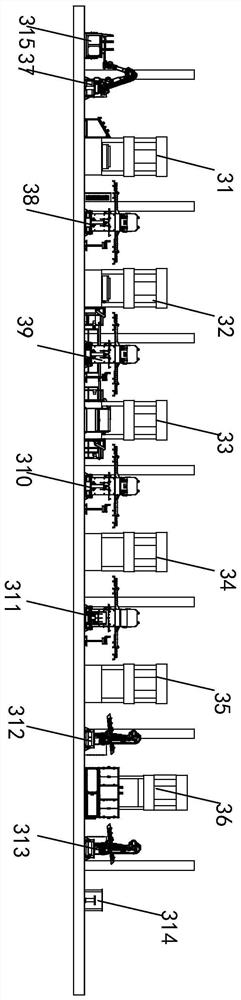

[0068] Embodiment one, such as Figure 1 to Figure 18 As shown, a fully automatic robot riveting production line for large home appliance boxes, including a box plate stacking platform 315, a first grabbing robot 37, a first stamping die 31, a first feeding manipulator 38, and a second stamping die 32 arranged in sequence , the second feeding manipulator 39, the third stamping die 33, the third feeding manipulator 310, the fourth stamping die 34, the fourth feeding manipulator 311, the fifth stamping die 35, the second grasping robot 312, the sixth stamping die 36 and Stand 314 is placed.

[0069] The box board material stacking platform 315 is used for stacking a plurality of box boards 316 to be stamped;

[0070] The first grabbing robot 37 is used to grab the box plate 316 on the stack to the first stamping die 31 .

[0071] The first stamping die 31 is used to stretch the box plate 316 .

[0072] The first feeding manipulator 38 is used to deliver the stretched box plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com