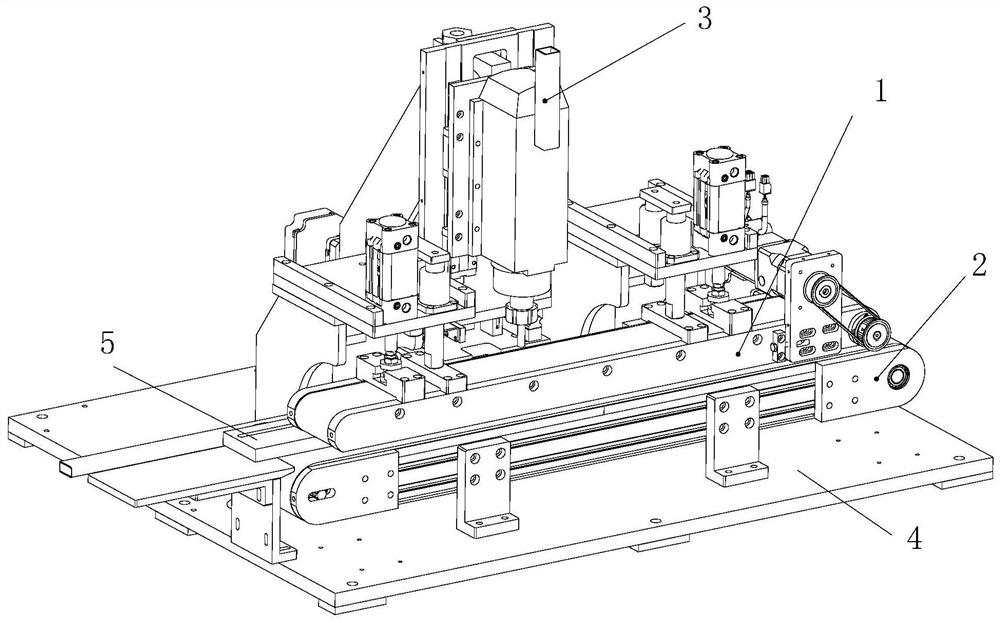

A method and device for groove processing of small and medium-sized plates for customized furniture

A small-size, plate-based technology, applied in wood processing equipment, manufacturing tools, special forming/shaping machines, etc., can solve the problems of easy fatigue, low processing precision, safety accidents, etc., to reduce production occupation area, production The effect of high efficiency and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

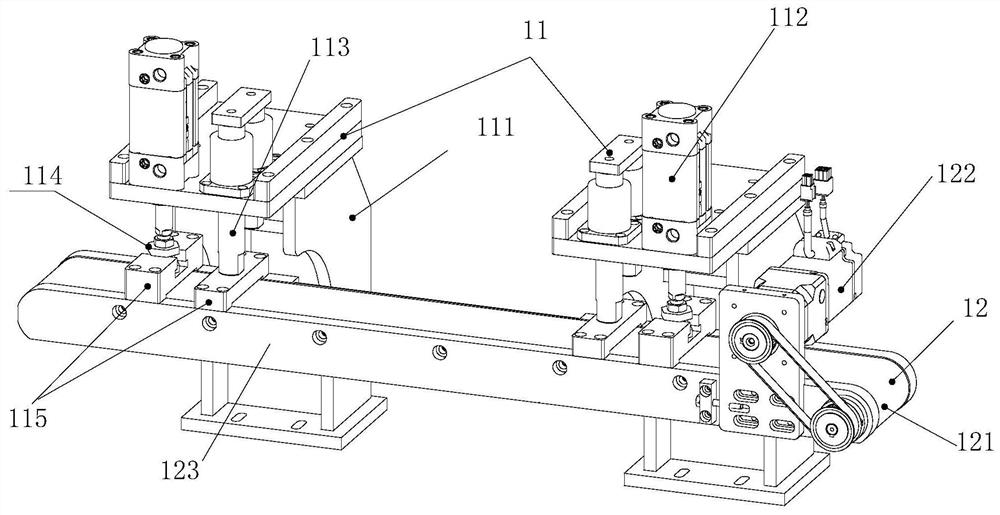

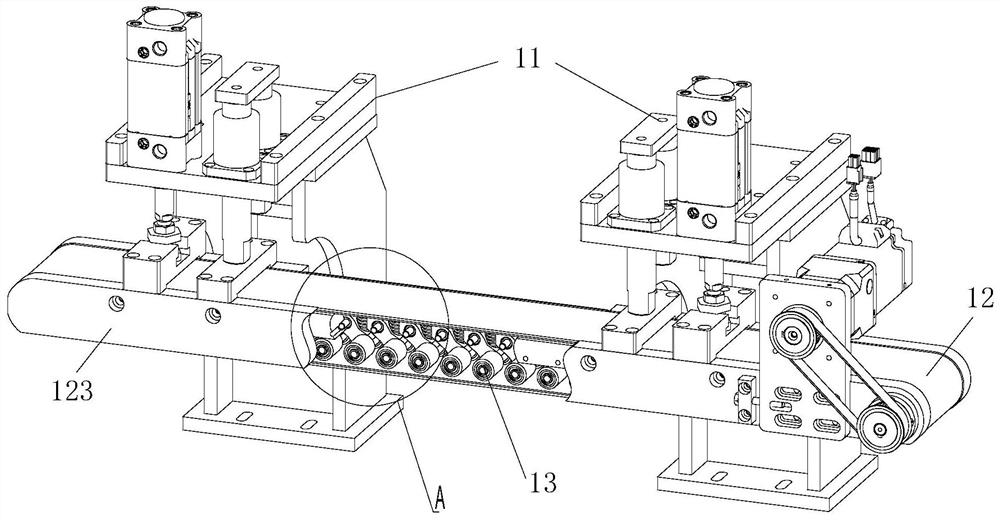

[0046] In this embodiment, a method for processing small and medium-sized plates for customized furniture:

[0047] Scan the sheet label to obtain sheet information and sheet groove information;

[0048] The plate is placed on the belt conveying mechanism to be transported in a straight line from the feeding area to the discharging area. The plate transmission process passes through the slotting station; when the plate enters the slotting station, the plate is held by the belt pressing plate mechanism, and the belt The pressing plate mechanism cooperates with the belt conveying mechanism to make the plate in the state of pressing and positioning, and the upper and lower bottom surfaces are driven by synchronous friction to realize the plate transmission; according to the plate grooving information, the plate is grooved.

[0049] The method of the present invention can realize the automatic processing of the drawing groove directly on the transmission line without moving the pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com