Prefabricated enclosing wall hollow slab and manufacturing device thereof

A technology for manufacturing devices and hollow slabs, which is applied in the direction of supply devices, unloading devices, manufacturing tools, etc., can solve the problems of inconvenient fixing molds for prefabricated fence production devices, high production costs of prefabricated fences, etc., to achieve convenient and fast replacement and fixation, and easy promotion The effect of using and saving investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A prefabricated wall hollow slab, including 150 parts of stone powder, 26.5 parts of fly ash, 53 parts of cinder, 53 parts of construction waste and hair materials, 100 parts of cement, and 15 parts of water:

[0035] A prefabricated wall hollow slab is manufactured by the following method:

[0036] S1. Pour stone powder, fly ash, coal cinder, construction waste and raw materials, cement and water into the mixer in proportion and stir evenly;

[0037]S2. Pour the uniformly stirred raw materials into the battery feeder, and then transport them to the plate-making automatic unloading machine;

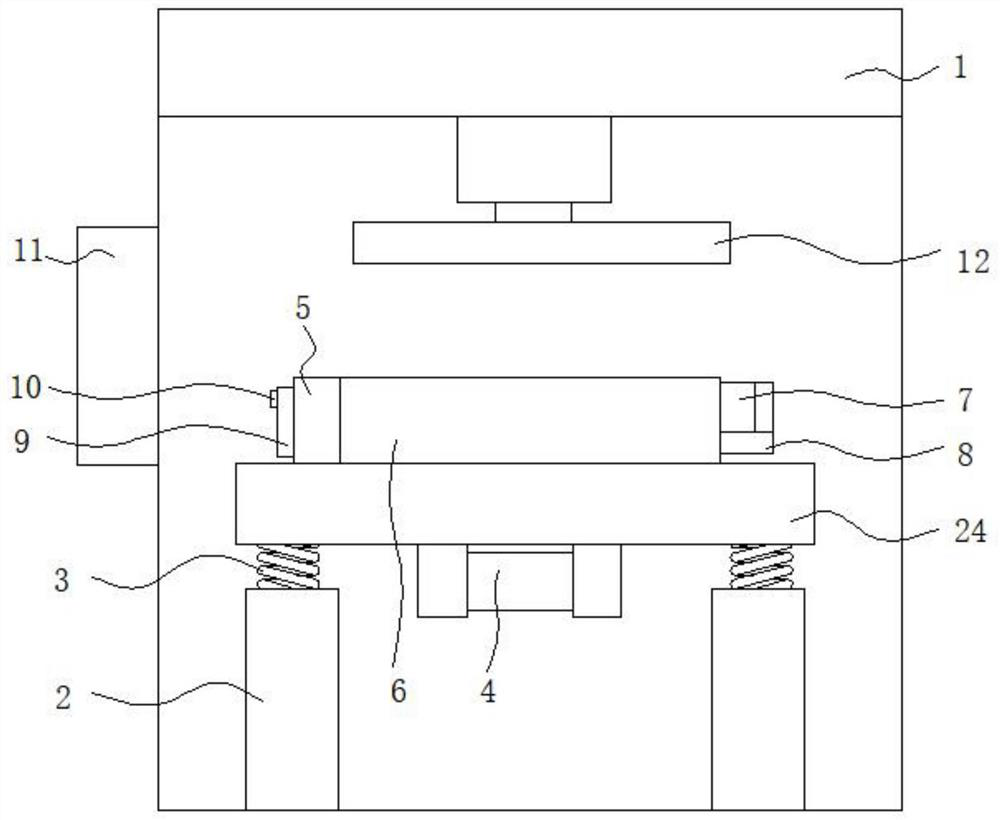

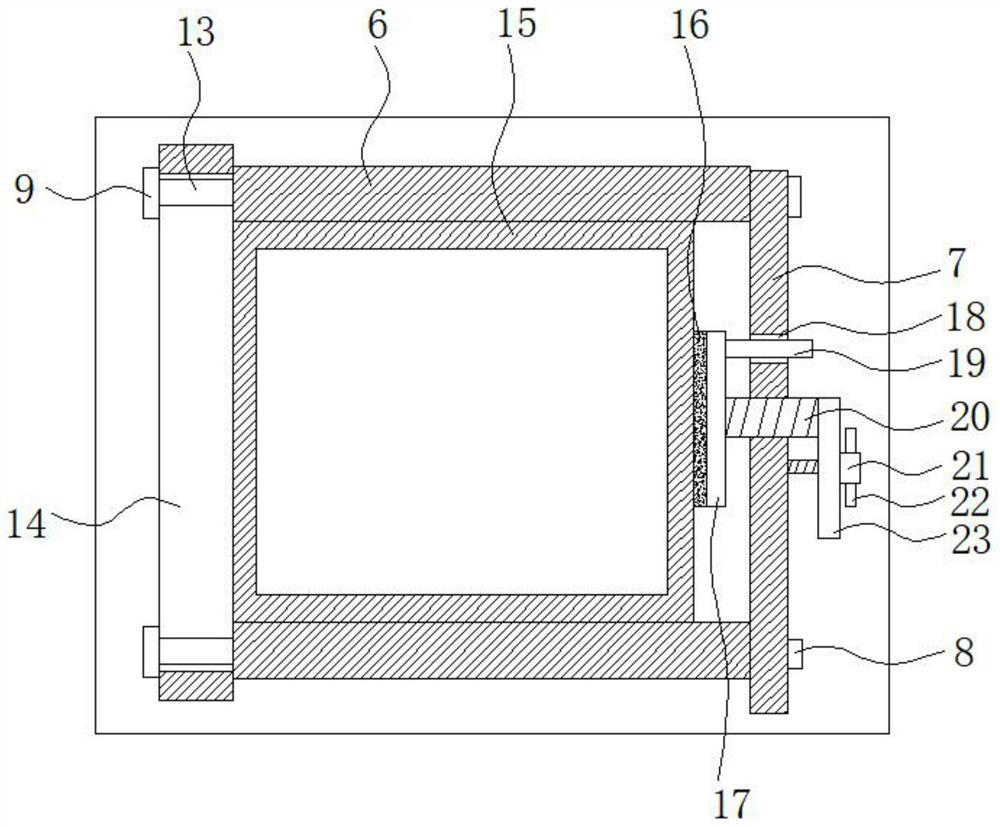

[0038] S3. Select a mold 15 of appropriate specifications according to the required size, and then place the mold 15 inside the mold fixture, then loosen the positioning bolts 10 on the two connecting plates 9, and then move the two side plates 6 , so that the two side plates 6 abut against both sides of the mold 15, then tighten the positioning bolts 10, then place one end of the...

Embodiment 2

[0043] A prefabricated wall hollow slab, including 175 parts of stone powder, 29 parts of fly ash, 58 parts of cinder, 58 parts of construction waste and hair materials, 125 parts of cement, and 18 parts of water:

[0044] A prefabricated wall hollow slab is manufactured by the following method:

[0045] S1. Pour stone powder, fly ash, coal cinder, construction waste and raw materials, cement and water into the mixer in proportion and stir evenly;

[0046] S2. Pour the uniformly stirred raw materials into the battery feeder, and then transport them to the plate-making automatic unloading machine;

[0047] S3. Select a mold 15 of appropriate specifications according to the required size, and then place the mold 15 inside the mold fixture, then loosen the positioning bolts 10 on the two connecting plates 9, and then move the two side plates 6 , so that the two side plates 6 abut against both sides of the mold 15, then tighten the positioning bolts 10, then place one end of the ...

Embodiment 3

[0052] A prefabricated wall hollow slab, including 200 parts of stone powder, 32 parts of fly ash, 65 parts of cinder, 65 parts of construction waste and hair materials, 150 parts of cement, and 25 parts of water:

[0053] A prefabricated wall hollow slab is manufactured by the following method:

[0054] S1. Pour stone powder, fly ash, coal cinder, construction waste and raw materials, cement and water into the mixer in proportion and stir evenly;

[0055] S2. Pour the uniformly stirred raw materials into the battery feeder, and then transport them to the plate-making automatic unloading machine;

[0056] S3. Select a mold 15 of appropriate specifications according to the required size, and then place the mold 15 inside the mold fixture, then loosen the positioning bolts 10 on the two connecting plates 9, and then move the two side plates 6 , so that the two side plates 6 abut against both sides of the mold 15, then tighten the positioning bolts 10, then place one end of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com