Multi-injection-unit co-molding equipment and method for large complex plastic product

A technology for plastic products and injection units, which is applied in the field of polymer material processing machinery, can solve the problems of long molding cycle time, increase injection volume, and lengthen processing cycle, so as to solve the problem of complex design structure, improve product molding quality, and improve production. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

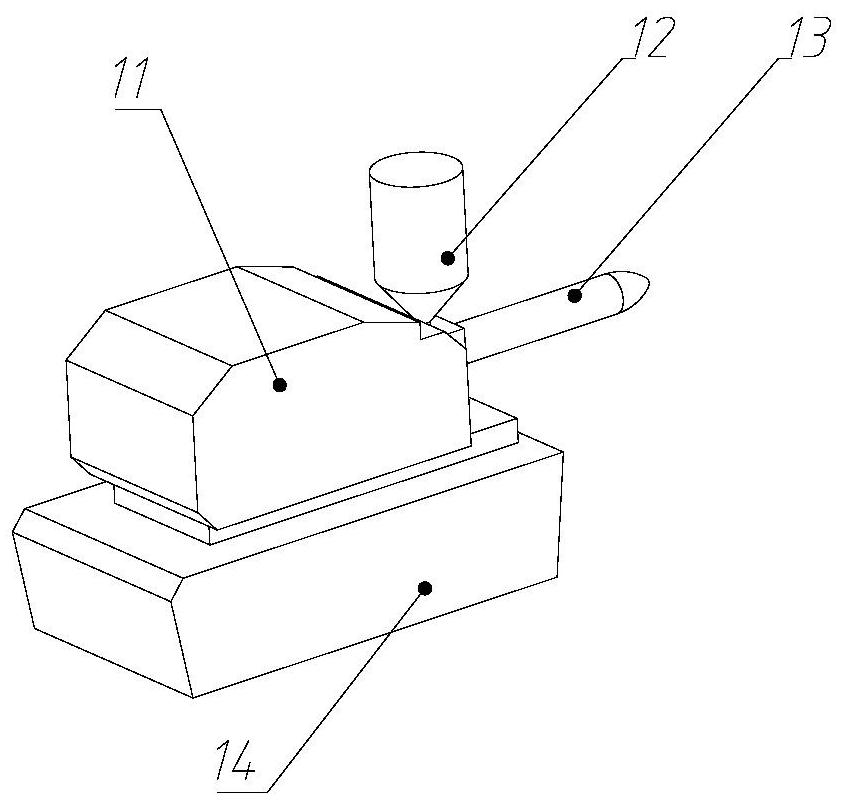

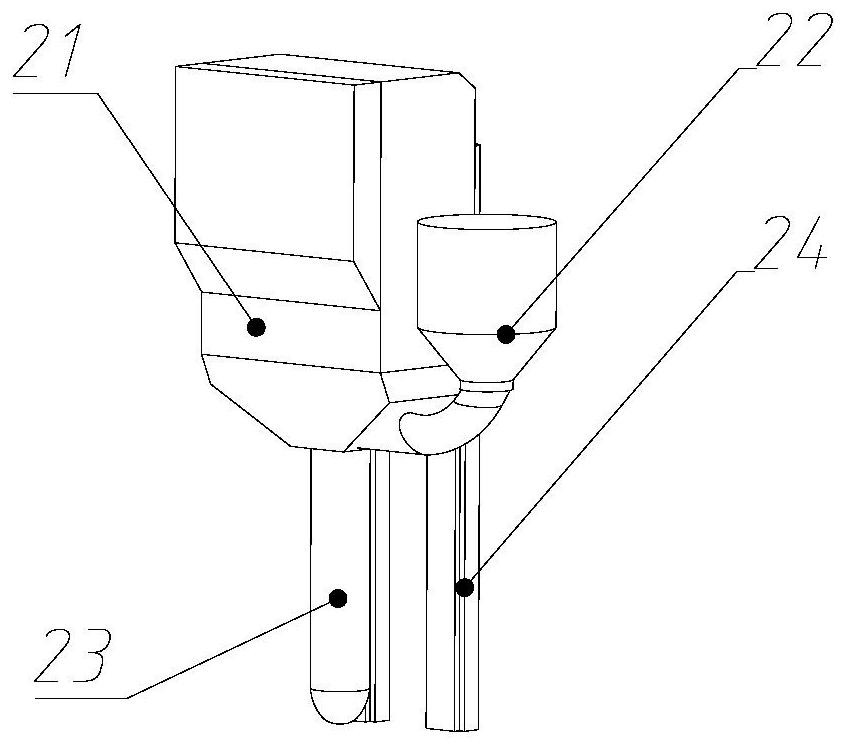

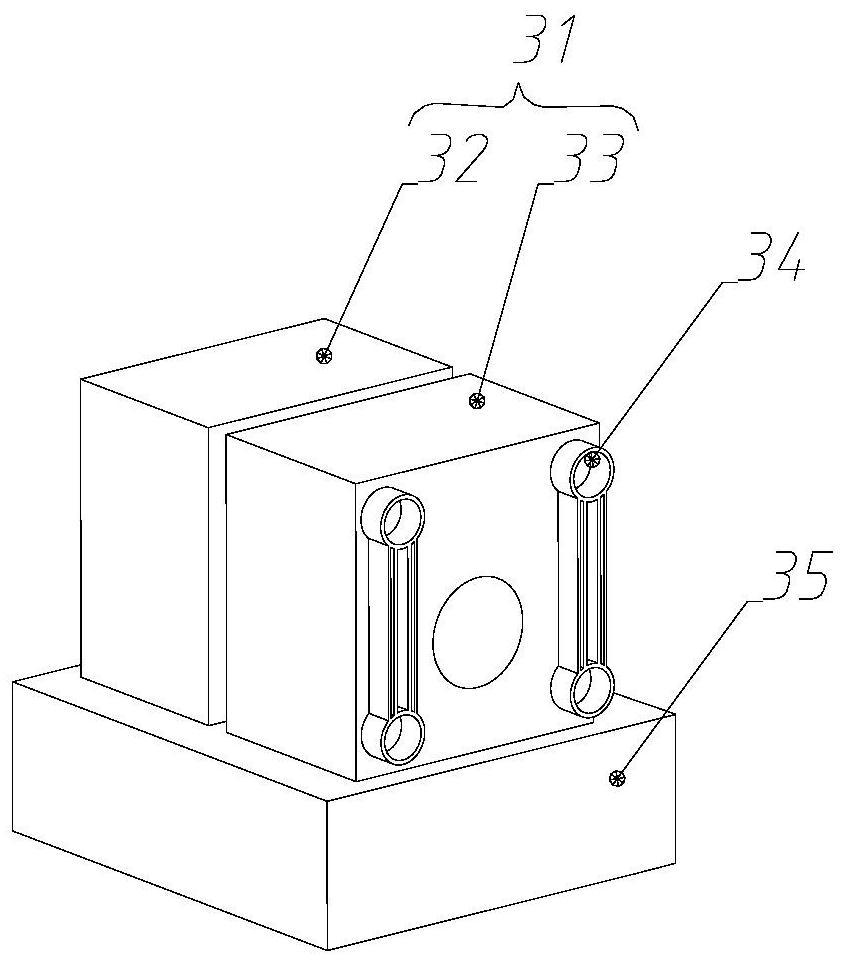

[0036] Figure 1 is a first embodiment of a multi-injection unit of the present invention, a multi-injection unit, and a primary structure comprising two horizontal independent injection units 1, a separate co-plastic coordinated mode unit 3. The horizontal independent injection unit 1 includes a seat 11, a hopper 12, a screw barrel 13, a base 14; a separate co-plastic coordinate mode unit 3 includes a molding apparatus 31, a locking device 34, and a moving driving device 35. The locking device is from the front template 32, the rear template 33.

[0037] In the present embodiment, the moving of the plastic article is mounted on the front template 3 and the rear template 4 in the independent common plastic coordinated module, respectively. The two horizontal independent injection units 1 are arranged on both sides of the independent co-plastic coating unit 3, and their screw barrels 13 are adjusted to align the through holes on the front template 32, the rear template 33, respectiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com