Wing assembly and hovercar

A wing and assembly technology, applied in the field of flying cars, can solve the problems of a large number of structural parts, a long assembly cycle, and a large number of fasteners, so as to achieve strong resistance to torsional loads, low difficulty in adhesive bonding and assembly, and reduce energy loss. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

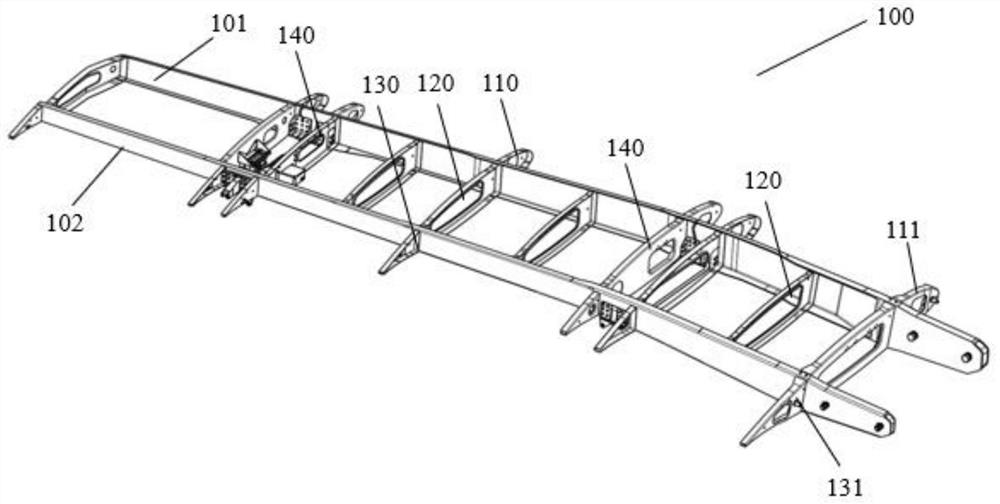

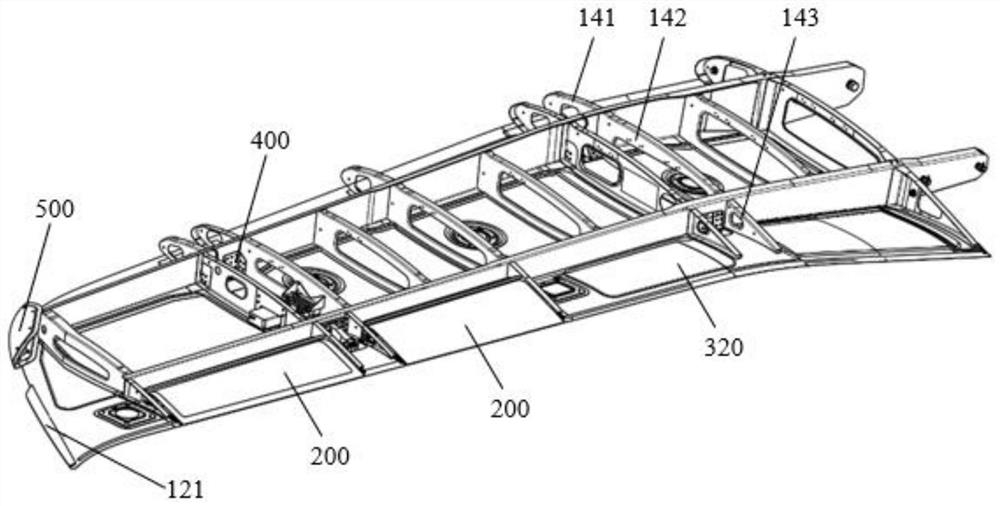

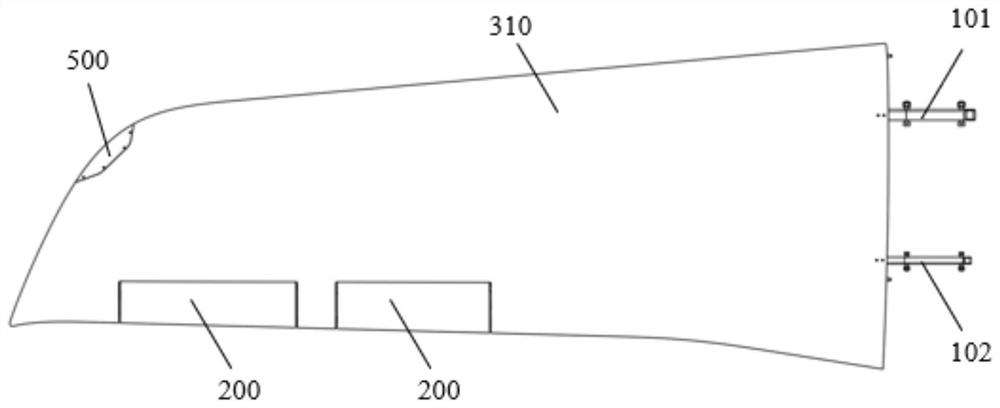

[0047] This embodiment provides a wing assembly, which can provide an installation location for the lift system of the aircraft, transfer the load of the lift system to the fuselage through the structure of the wing assembly, and provide the pulling force and The aerodynamic pulling force generated by the wing assembly in the cruising phase, the load transmission path is simple and direct, and the safety factor is high. Figure 1-5 As shown, the wing assembly includes an outer skin assembly 300 with closed edges, a wing skeleton 100 fixedly arranged inside the outer skin assembly 300, and a double aileron located at the rear side of the wing skeleton 100, wherein the wing The skeleton 100 and the double ailerons are all made of composite materials, so that the wing assembly has the advantages of light weight, simple connection process, and short assembly cycle; in a possible implementation of this specification, the composite material can preferably be carbon fiber composite T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com