High-frequency high-temperature low-loss mnzn power ferrite material and preparation method thereof

A ferrite material and low-loss technology, applied in the field of low-loss ferrite material and preparation, can solve problems such as difficulty in maintaining low loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

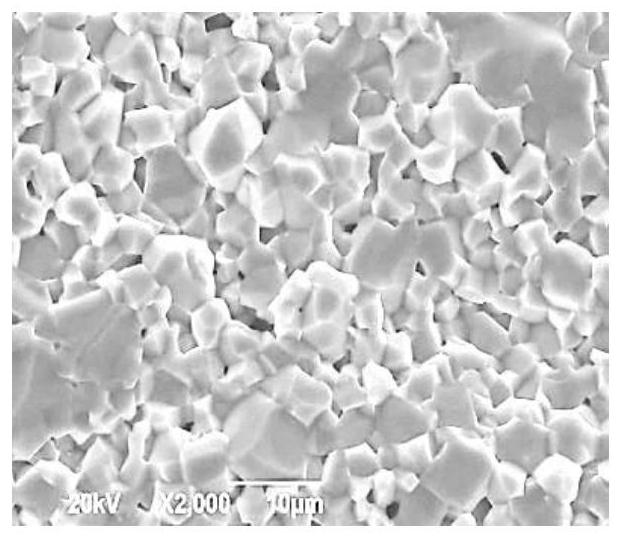

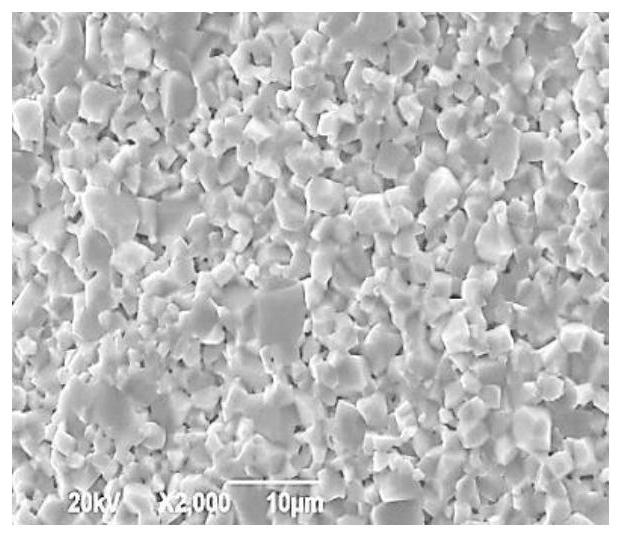

Image

Examples

preparation example Construction

[0063] The preparation method of a high-frequency, high-temperature, low-loss MnZn power ferrite material of the present invention uses MnZn ferrite powder material as a raw material, and includes the following method steps:

[0064] 1) The main raw material is prepared and processed,

[0065] First, the main raw material components of different particle sizes in the above proportions are sieved through 100-200 mesh and then pretreated and mixed to form the main raw material pretreatment material; the pretreatment mixing is to mix the proportioned main raw materials The sieved powder particles of the components are dehumidified, and then mixed for 15-60 minutes at a temperature of 40-90 °C, and the main raw material is pre-treated;

[0066] 2) A primary grinding treatment,

[0067] The main raw material pretreatment material prepared in step 1) is placed in a ball milling device, subjected to initial grinding activation treatment, and drying treatment is carried out to contro...

Embodiment

[0086] Aiming at the technical problem that the existing high-frequency MnZn power ferrite material is difficult to maintain low loss at high temperature, the present invention provides a high-frequency high-temperature ultra-low loss MnZn power ferrite material and a preparation method thereof, which are: using BaTiO 3 (BTO) the same below, particle doping improves the resistivity temperature characteristics of MnZn power ferrite, while refining the grain, and finally suppresses the loss of MnZn power ferrite at high frequency and high temperature. First by preferably high-purity Fe 2 O 3 , Mn 3 O 4 and ZnO as raw materials, Fe 2 O 3 and ZnO content on the performance of high-frequency MnZn power ferrite, and the optimal main formula range was determined. CaCO 3 , V 2 O 5 , Co 2 O 3 , TiO 2 , SnO 2 , BTO, and CaCu 3 Ti 4 O 12 (CCTO) the same below, doping with other additives to control the microstructure and electromagnetic properties of high-frequency MnZn p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com