Verification method of microwave-assisted biological enzyme catalytic reaction

A microwave-assisted, catalytic reaction technology, applied in the field of biological enzymes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

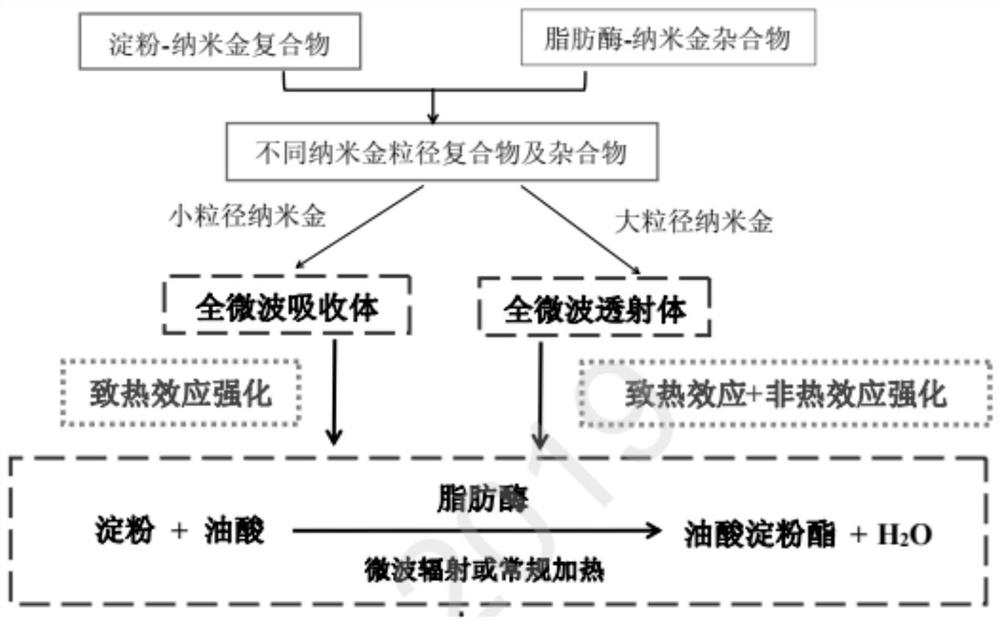

[0028] This example provides a method for verifying microwave-assisted biological enzyme-catalyzed reactions, which is used to reveal the role of microwave radiation in enzymatically-catalyzed reactions, and to determine the principle of microwave radiation improving enzyme-catalyzed reactions.

[0029] The verification method of the microwave-assisted biological enzyme-catalyzed reaction provided in this embodiment includes the following steps:

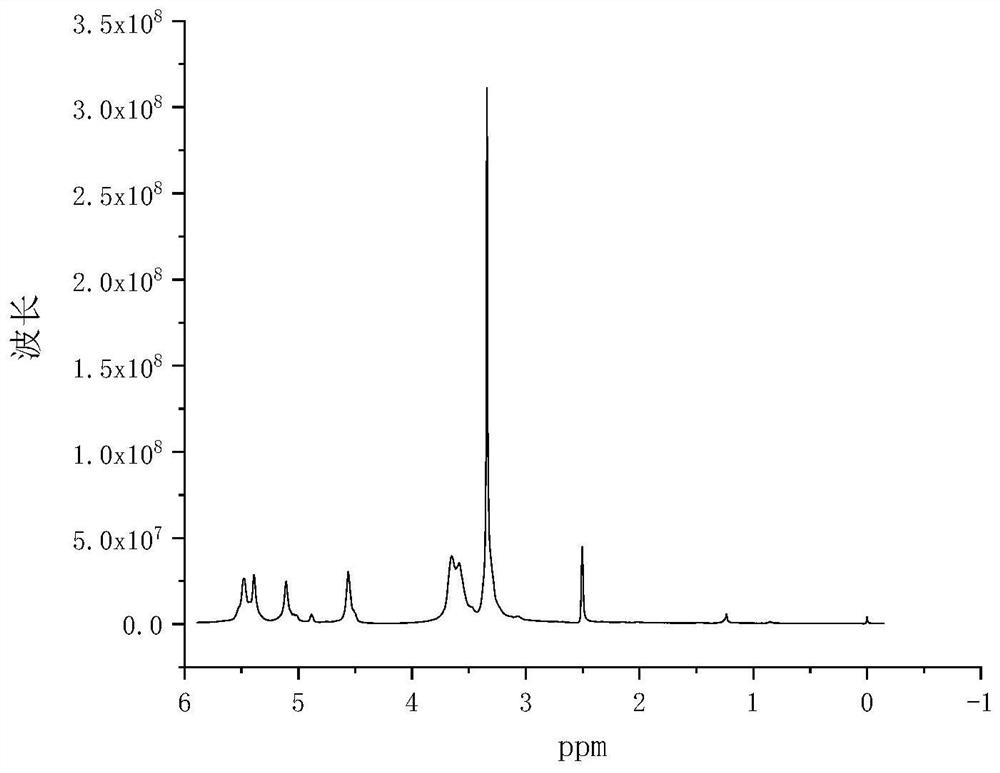

[0030] S1. Mix cornstarch with different concentrations of chloroauric acid heated to boiling according to the mass ratio of 1:0.06. The mass concentration of the chloroauric acid is 0.001%-0.01%, and react for 15s to prepare starch-gold particle composite The average particle size of the prepared gold particles is 1nm-10μm.

[0031] S2. Add Candida antarctica lipase to the chloroauric acid solution with a mass concentration of 0.01%, react in a constant temperature oscillator at 35° C. for 36 hours, wherein the mass ratio of chloroa...

Embodiment 2

[0036] This embodiment provides a verification method for a microwave-assisted biological enzyme-catalyzed reaction, which includes the following steps:

[0037] S1. Mix cornstarch with different concentrations of chloroauric acid heated to boiling according to the mass ratio of 1:0.3, the mass concentration of the chloroauric acid is 0.001%-0.01%, and react for 15s to prepare starch-gold particle composite The average particle size of the prepared gold particles is 1nm-10μm.

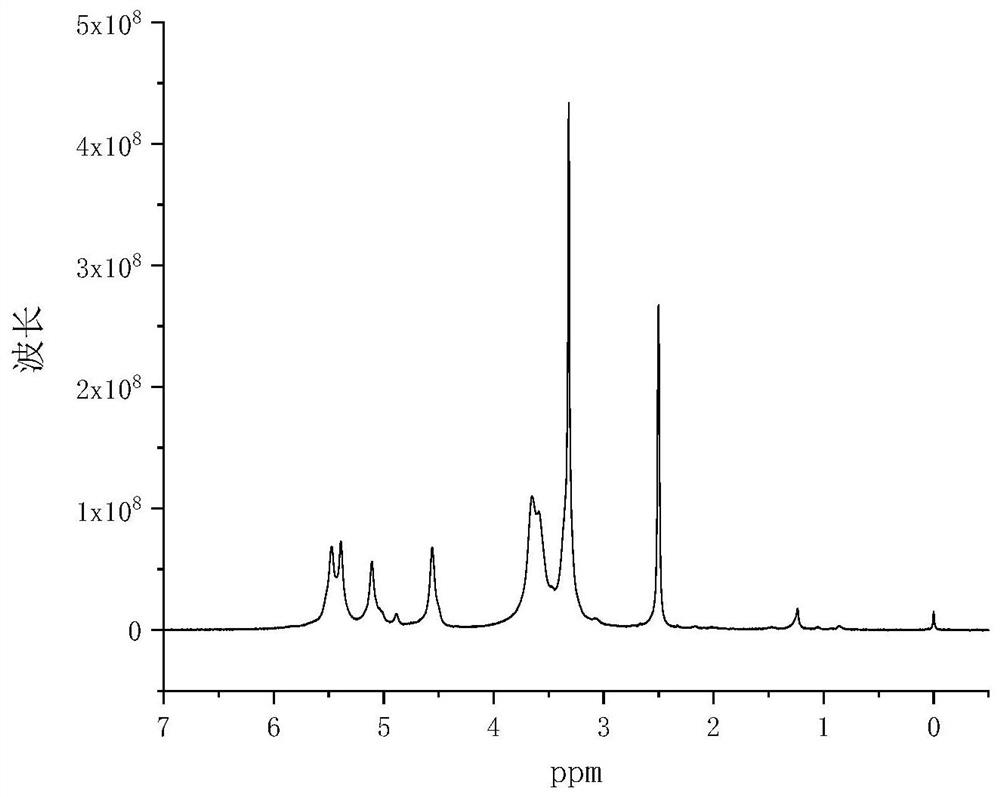

[0038] S2. Add Candida antarctica lipase to the chloroauric acid solution with a mass concentration of 0.01%, react in a constant temperature oscillator at 35° C. for 36 hours, wherein the mass ratio of chloroauric acid to Candida antarctica lipase is 1 : 4.5, lipase-gold particle hybrids are obtained, and in the hybrids, the average particle diameter of the gold particles is 1nm-10 μm.

[0039] S3. Mix the starch-gold particle complex obtained in step S1 with oleic acid, and add the lipase-gold partic...

Embodiment 3

[0043] This embodiment provides a verification method for a microwave-assisted biological enzyme-catalyzed reaction, which includes the following steps:

[0044] S1. Mix the activated cornstarch with different concentrations of auric acid chloride heated to boiling according to the mass ratio of 1:0.15, the mass concentration of the auric acid chloride is 0.001%-0.01%, and react for 15s to prepare starch- The gold particle composite, the average particle size of the prepared gold particles is 1nm-10μm.

[0045]S2. Add Candida antarctica lipase to the chloroauric acid solution with a mass concentration of 0.01%, react in a constant temperature oscillator at 35° C. for 36 hours, wherein the mass ratio of chloroauric acid to Candida antarctica lipase is 1 : 4, lipase-gold particle hybrids are obtained, and in the hybrids, the average particle diameter of the gold particles is 1nm-10 μm.

[0046] S3. Mix the starch-gold particle complex obtained in step S1 with oleic acid, and ad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com