Manufacturing and forming method for top cover of storage box

A top cover and storage tank technology, applied in the direction of manufacturing tools, furnace types, furnaces, etc., can solve the problems of poor hot air circulation, affecting the test rate, uneven heat flow distribution, etc., to improve the problem of inconvenient positioning, improve Thermomechanical coupling conditions, the effect of solving the problem of heat flow stagnation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A method for manufacturing a top cover of a storage tank,

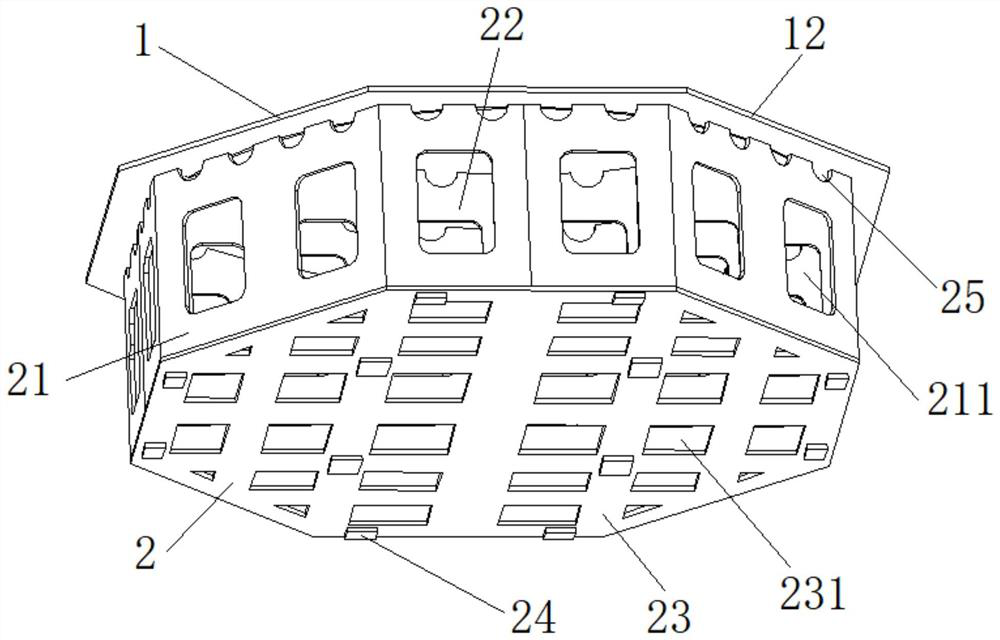

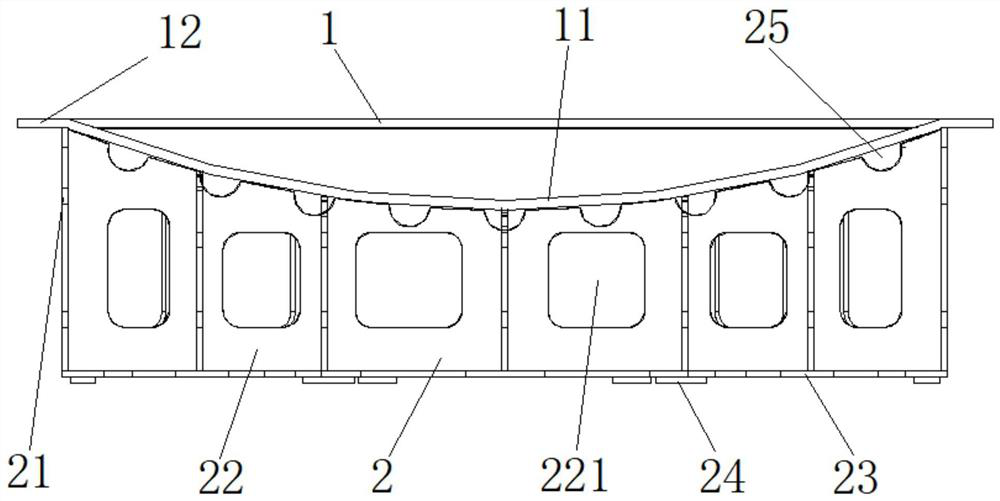

[0033] Design a kind of storage tank top cover mold first, described storage tank top cover mold comprises the mold type panel 1 that is used to make the storage tank top cover shape and is arranged on the bottom bracket 2 that is used for supporting and heat dissipation under the mold type panel 1;

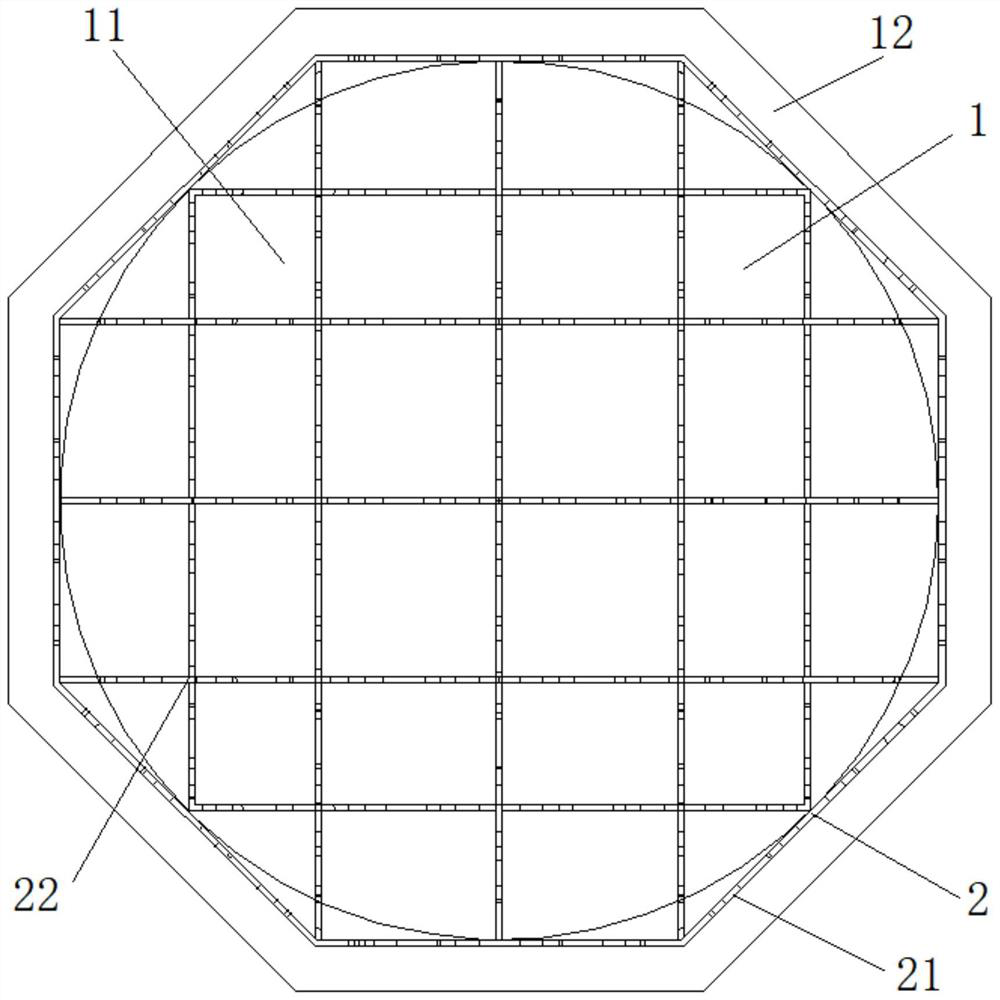

[0034] The mold-shaped panel 1 includes a profile portion 11 located in the center of the mold-shaped panel and an end portion 12 surrounding the outside of the profile portion 11;

[0035] The profile part 11 is a concave curved panel with a circular outer edge; the end face part 12 is flat, the inner edge of the end face part 12 is fixedly connected with the outer edge of the profile part 11, and the outer edge of the end face part 12 It is a regular octagon, and the symmetrical centers of the profile part 11 and the end face part 12 coincide;

[0036] Described bottom bracket 2 comprises rib plate 22, the bott...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com