Preparation method of linen elastic fabric

An elastic and flax technology, which is applied in the processing of textile materials, fabric surface trimming, liquid/gas/steam textile processing, etc. The effect of improved recovery rate and improved elastic elongation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

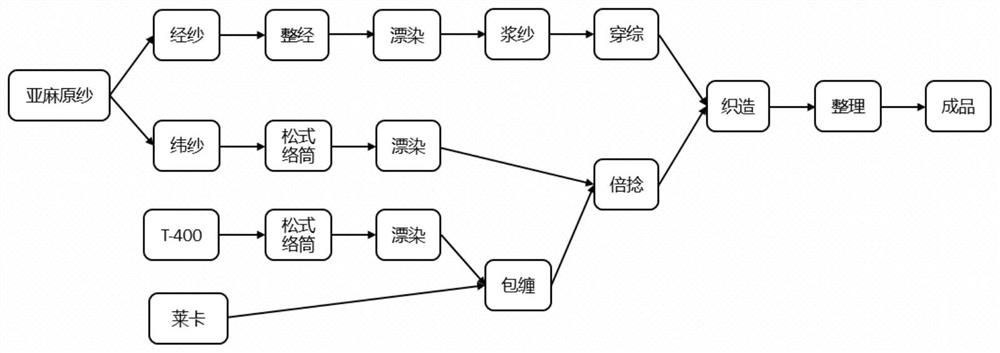

Method used

Image

Examples

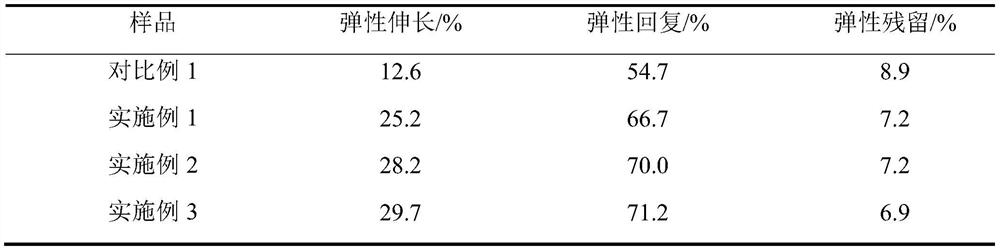

Embodiment 1

[0050] Navy blue linen elastic fabric: the warp is made of 21Ne linen fiber, the weft is made of 21Ne linen fiber + 30D / T400+105D Lycra, the width is 53 / 54 inches, the density is 70*56, and the weave is 1 / 1.

[0051] The preparation method of navy blue linen elastic fabric is as follows:

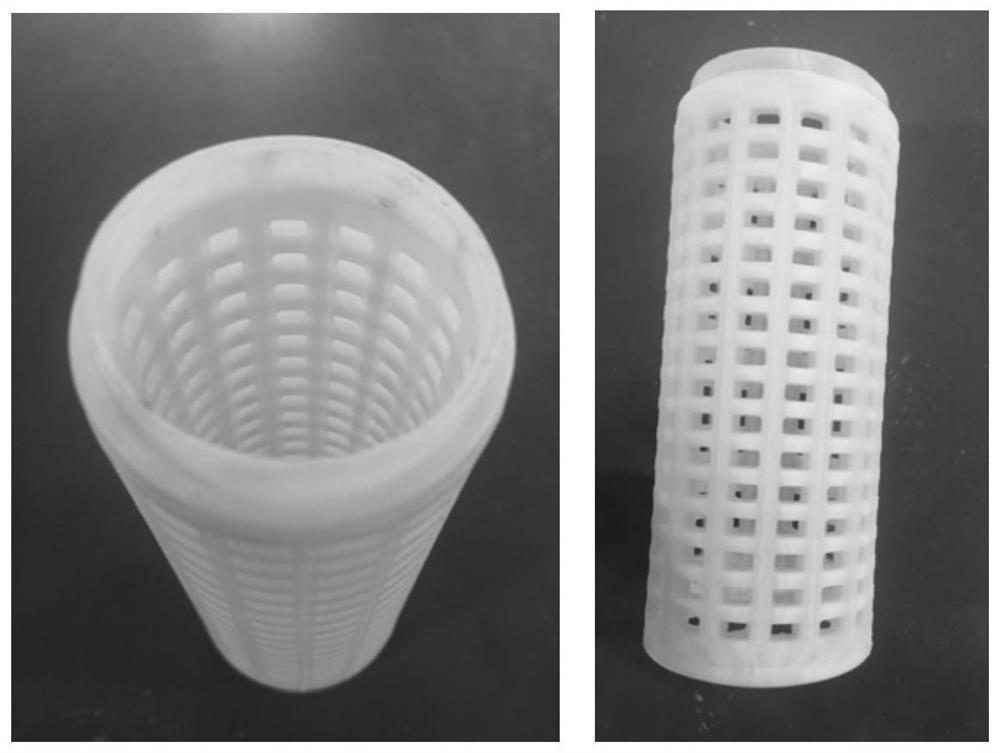

[0052] (1) Loose winding: The flax fiber raw yarn is wound on the loose tube through the loose winder to obtain the flax fiber bobbin yarn; T-400 yarn is wound on the loose tube through the loose winder , to obtain T-400 cheese;

[0053] (2) warping: the flax fiber raw yarn is warped on the warping machine to obtain a warping beam;

[0054] (3) Bleaching and dyeing: the flax fiber package obtained in step (1) is bleached and dyed, the bleaching temperature is 55° C., the bleaching time is 100 minutes, and dehydration is obtained to obtain dyed flax fiber yarn; the T obtained in step (1) is -400 bobbins are bleached and dyed, the bleaching temperature is 120 ℃, and the bleaching time is 60 ...

Embodiment 2

[0064] Navy blue linen elastic fabric: the warp is made of 21Ne linen fiber, the weft is made of 21Ne linen fiber + 50D / T400+75D Lycra, the width is 53 / 54 inches, the density is 70*56, and the weave is 1 / 1.

[0065] The preparation method of navy blue linen elastic fabric is as follows:

[0066] (1) Loose winding: The flax fiber raw yarn is wound on the loose tube through the loose winder to obtain the flax fiber bobbin yarn; T-400 yarn is wound on the loose tube through the loose winder , to obtain T-400 cheese;

[0067] (2) warping: the flax fiber raw yarn is warped on the warping machine to obtain a warping beam;

[0068] (3) Bleaching and dyeing: the flax fiber package obtained in step (1) is bleached and dyed, the bleaching temperature is 60° C., the bleaching time is 90 minutes, and dehydration is obtained to obtain dyed flax fiber yarn; the T obtained in step (1) is -400 bobbins are bleached and dyed, and the bleaching and dyeing temperature is 125 ℃, and the bleachin...

Embodiment 3

[0078] Navy blue linen elastic fabric: the warp is made of 30Ne linen fiber, the weft is made of 30Ne linen fiber + 75D / T400+40D Lycra, the door width is 53 / 54 inches, the density is 70*56, and the weave is 1 / 1.

[0079] The preparation method of navy blue linen elastic fabric is as follows:

[0080] (1) Loose winding: The flax fiber raw yarn is wound on the loose tube through the loose winder to obtain the flax fiber bobbin yarn; T-400 yarn is wound on the loose tube through the loose winder , to obtain T-400 cheese;

[0081] (2) warping: the flax fiber raw yarn is warped on the warping machine to obtain a warping beam;

[0082] (3) Bleaching and dyeing: the flax fiber package obtained in step (1) is bleached and dyed, the bleaching temperature is 65° C., the bleaching time is 80 minutes, and dehydration is obtained to obtain dyed flax fiber yarn; the T obtained in step (1) is -400 packages are bleached and dyed, the bleaching temperature is 130 ℃, and the bleaching and dye...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elasticity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com