Textile fiber rolling machine

A textile fiber and kneading machine technology, which is applied in textiles and papermaking, fabric kneading/softening treatment, fabric surface trimming, etc., can solve problems such as fracture and damage to the quality of placed fibers, and avoid local overheating, avoid softening unevenly, The effect of ensuring the processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

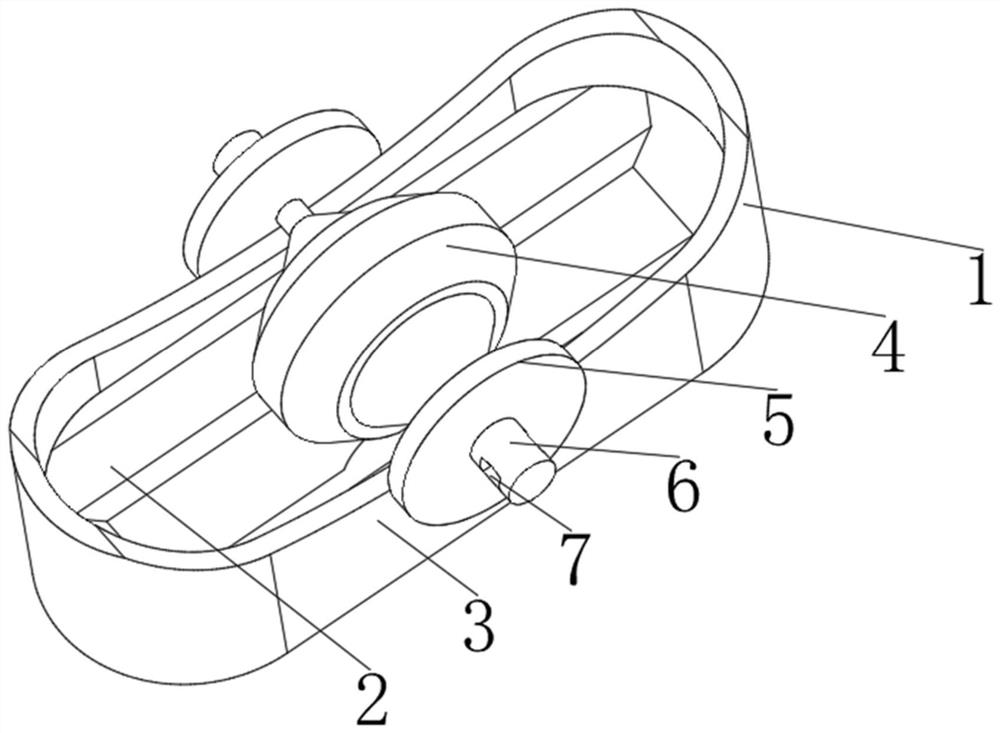

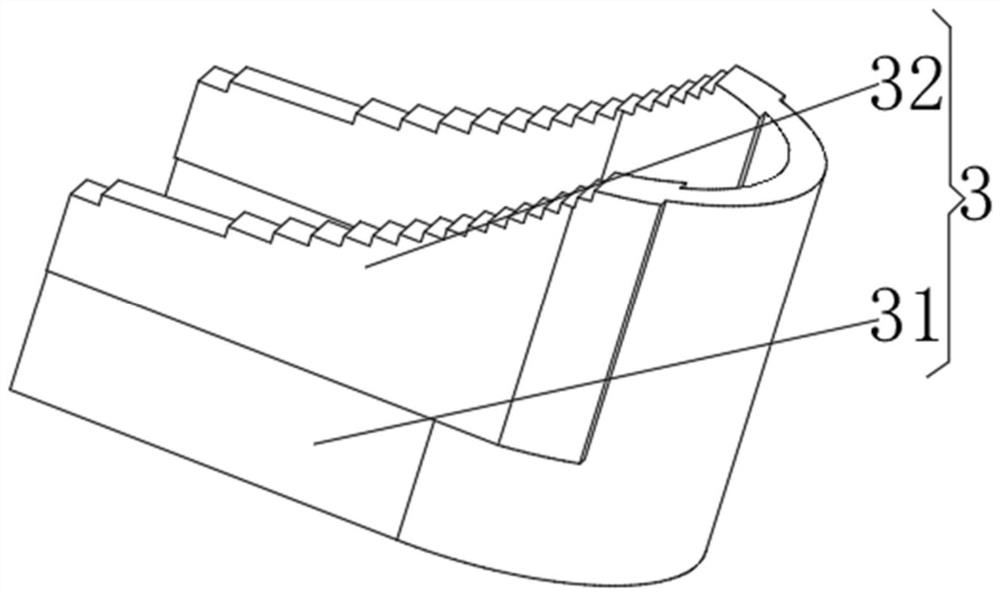

[0036] Such as Figure 1-6As shown, a kind of textile fiber kneading machine proposed by the present invention includes a protective box 1, the front and back of the bottom of the inner cavity of the protective box 1 are fixedly connected with a heat flow mechanism 2, and the tops of the front and back sides of the protective box 1 are fixed. A ladder mechanism 3 is connected, and the side of the ladder mechanism 3 away from the protection box 1 is fixedly connected with a kneading wheel 4, and the front and back of the kneading wheel 4 are fixedly connected with a limiting power generation disc 5, and the limiting power generation disc 5 is far away from the side of the kneading wheel 4. The side is fixedly connected with a hand lever 6, and the middle position on both sides of the hand lever 6 is provided with a through hole 7, and the outer surface of the kneading wheel 4 is movably connected with the heat flow mechanism 2.

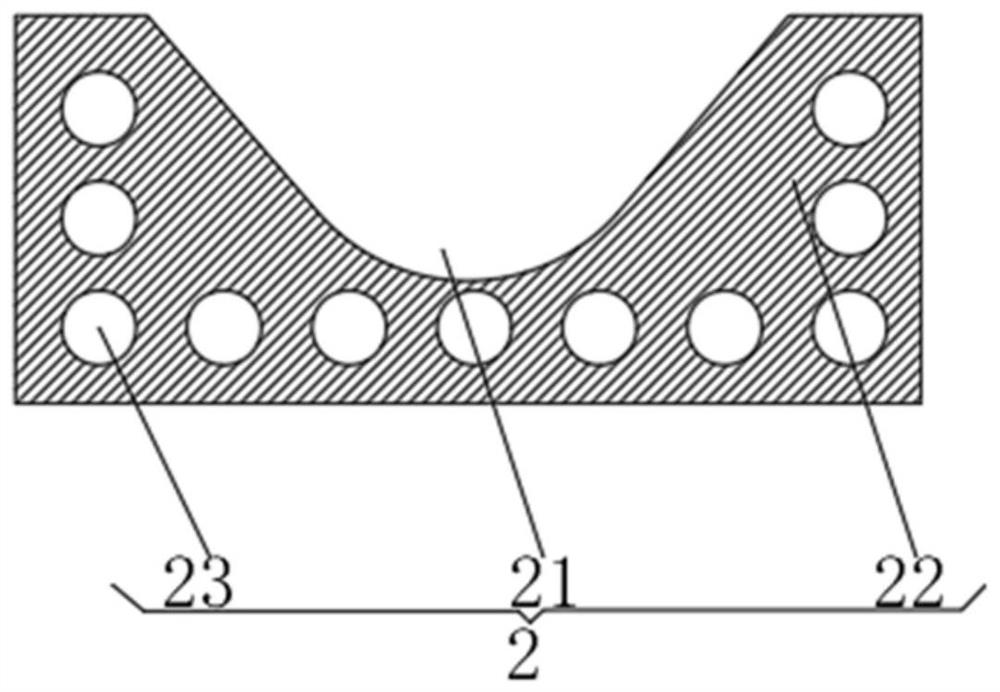

[0037] The heat flow mechanism 2 includes an arc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com