Double-layer self-circulation pressure-maintaining grouting pipe

A technology of grouting pipe and circulating pipe, applied in soil protection, construction, infrastructure engineering and other directions, can solve the problems of poor grouting uniformity and poor stability of grouting pipe, so as to reduce vibration, avoid vibration and improve uniformity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

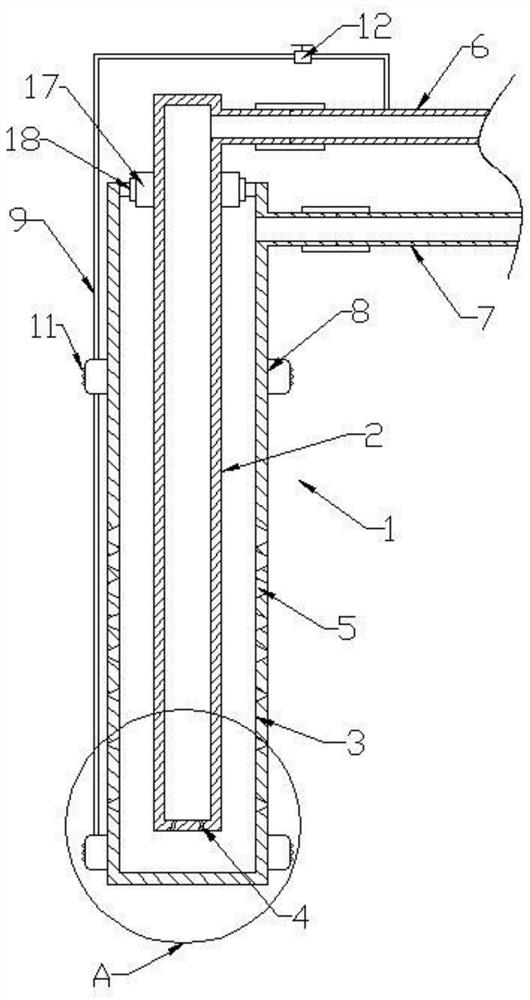

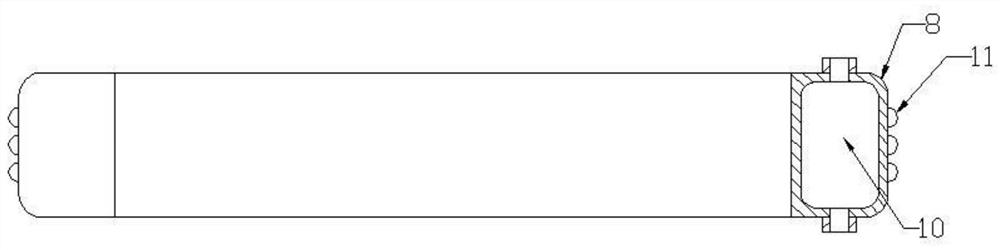

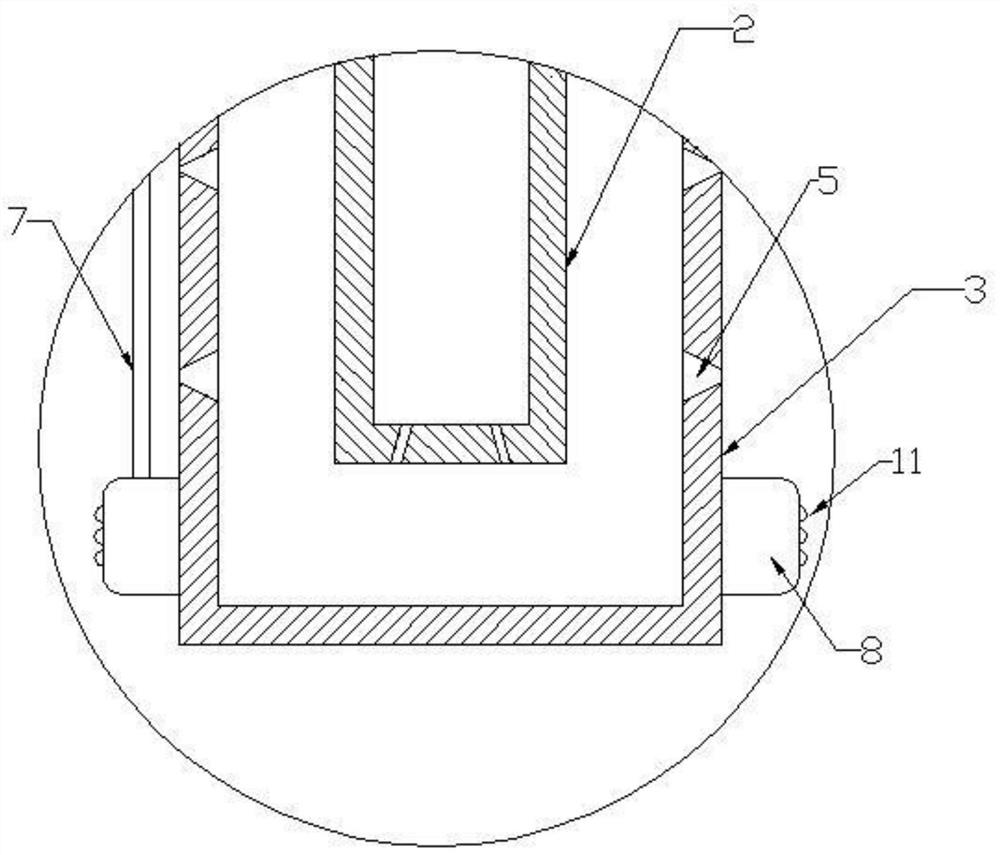

[0042] Such as Figure 1 to Figure 3 As shown, this embodiment provides a double-layer self-circulating pressure-maintaining grouting pipe, including a grouting pipe 1, and the grouting pipe 1 includes an inner pipe 2 and an outer pipe 3, and the upper part of the inner pipe 2 is fixedly provided with a fixed Disk 17, the two ends of the outer tube 3 are open structures, and the upper open end is provided with a fixing ring 18, and the fixing disk 17 is connected with the fixing ring 18 with a screw, so that the outer tube 3 is placed on the outer surface of the inner tube 2; The top of the inner pipe 2 is connected to the communication pipe 6, and the upper part of the side wall of the outer pipe 3 is connected to the circulation pipe 7, and the communication pipe 6 and the circulation pipe 7 are connected to the external grouting equipment, thereby forming a closed circulation loop;

[0043] The bottom surface of the inner tube 2 is evenly provided with a plurality of commun...

Embodiment approach 2

[0046] Such as Figure 4 with Figure 5 As shown, this embodiment discloses a double-layer self-circulating pressure-maintaining grouting pipe on the basis of Embodiment 1, including an inner pipe 2 and an outer pipe 3, the bottom of the outer pipe 3 is an open structure, and the outer The open end of the bottom of the pipe 3 is sealed by a flow diversion cover 13 connected by a screw thread. The outer edge of the flow diversion cover 13 is provided with an arc-shaped second flow guide surface 14. The center of the flow diversion cover 13 is provided with the right top and the inner pipe 2. The dividing column 15 abutting against the bottom surface is provided with an arc-shaped first guide surface 16 on the side of the divider column 15 , and the first guide surface 16 is smoothly connected with the second guide surface 14 .

[0047] When the present invention is used, the external grouting equipment pressurizes the prepared slurry from the connecting pipe into the inner pip...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap