Automatic wire burying device for water conservancy and hydropower engineering

A water conservancy, hydropower and engineering technology, applied in the field of electric embedding, can solve problems such as poor practicability, inability to adjust depth, damage, etc., and achieve the effect of improving practical performance, improving burial effect, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

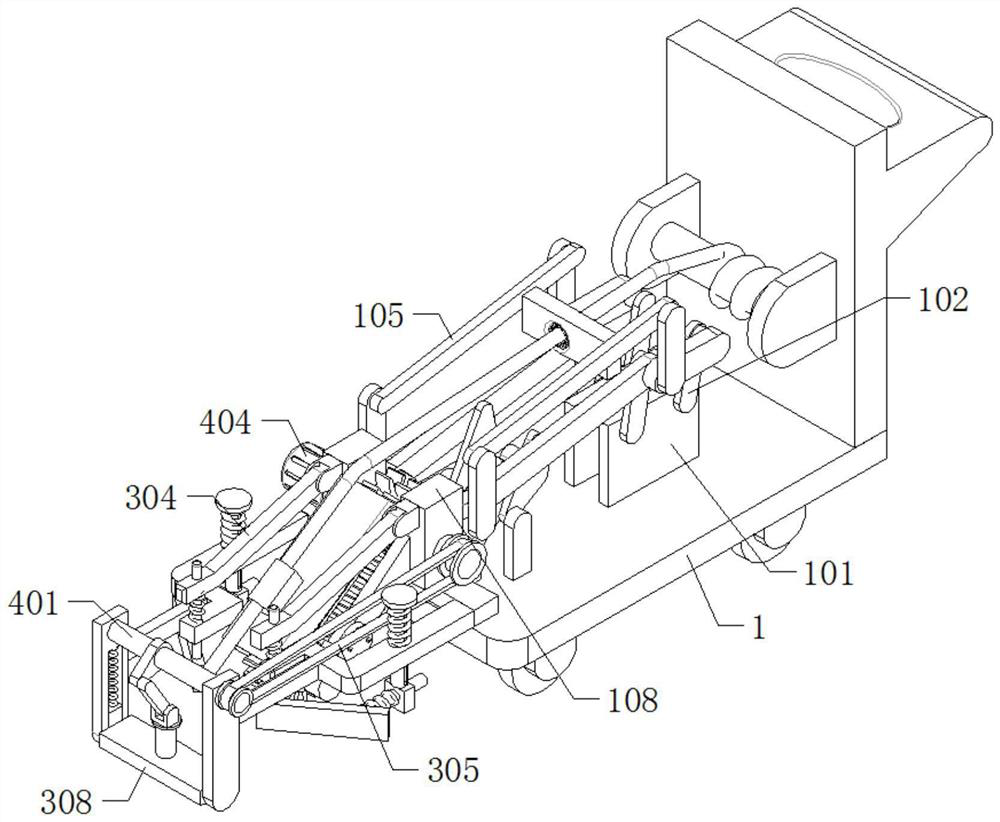

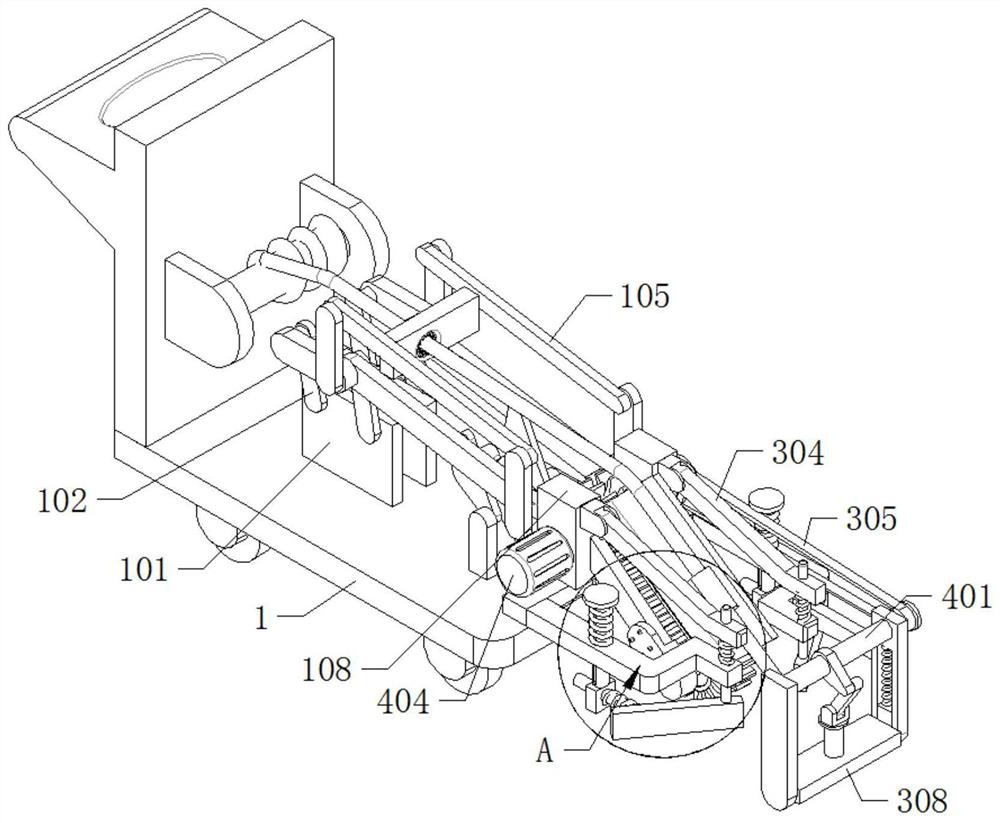

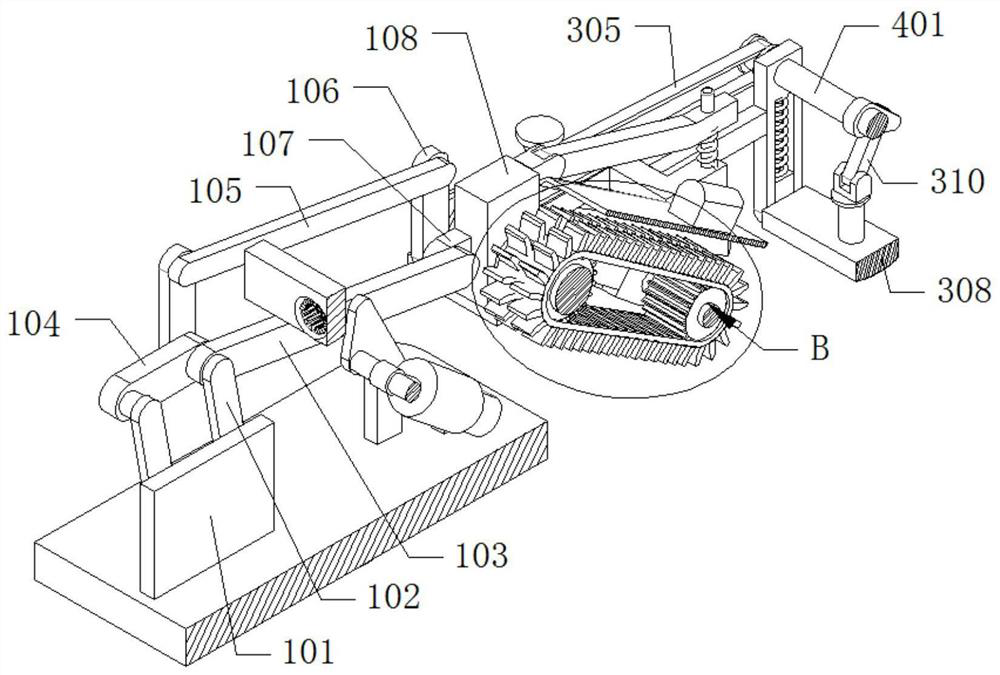

[0031] refer to Figure 1-7, an automatic thread embedding device for water conservancy and hydropower projects, comprising a car body 1, a fixed plate 101 and a cylinder 110, the fixed plate 101 and the cylinder 110 are connected on the top wall of the car body 1, and the outer wall of the fixed plate 101 is rotationally connected There is a first connecting plate 102, the outer wall of the first connecting plate 102 is connected with a lifting device, the end of the lifting device away from the fixed plate 101 is connected to the outer wall of the output end of the cylinder 110, and the other end of the lifting device is connected with a fixed seat 107 , the outer wall of the fixed seat 107 is connected with a fixed frame 108, the outer wall of the fixed frame 108 is connected with a first connecting plate 206 and a drive motor 404, and the output end of the drive motor 404 is connected with a first drive shaft 2, the The outer wall of the first driving shaft 2 is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com