Refrigeration equipment cloud intelligent performance matching system and method

A refrigeration equipment, cloud technology, applied in signal transmission systems, measuring devices, instruments, etc., can solve the problems of rising development costs, waste of laboratory and human resources, waste of time, etc., to save working condition stabilization time and experimental power consumption The effect of saving and eliminating refrigerant loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

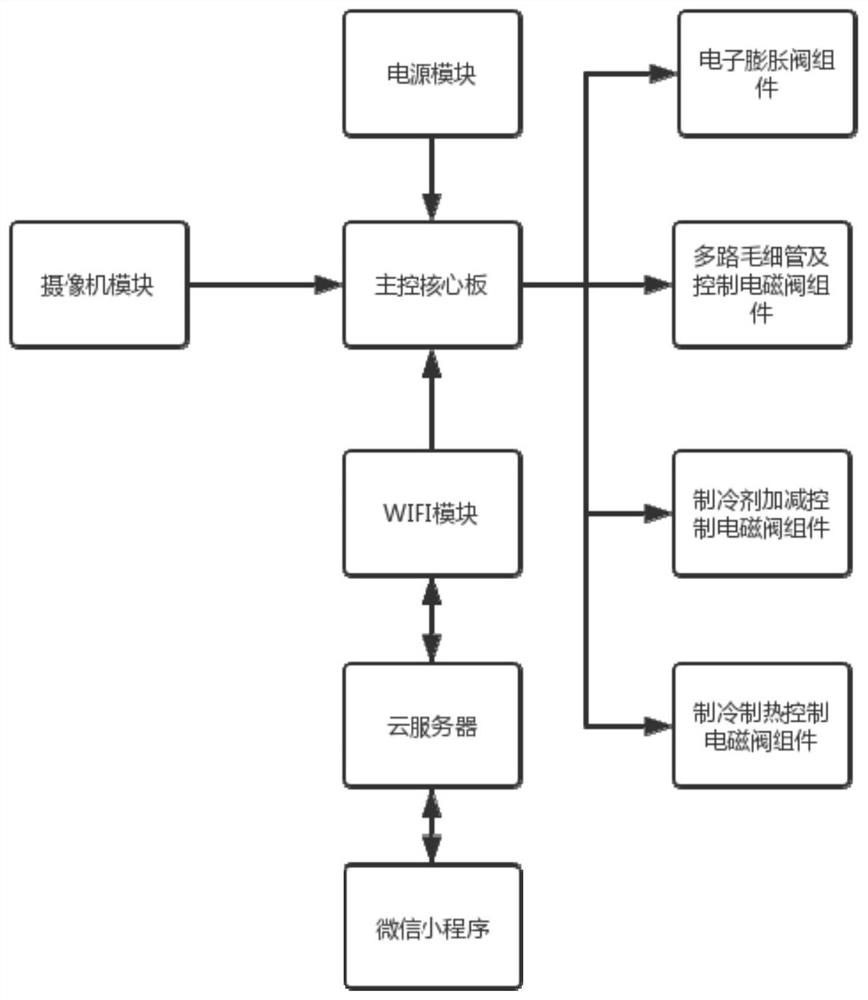

[0025] Such as figure 1 As shown, the cloud intelligent performance matching system in this embodiment includes a main control core board, a WIFI module, a cloud server, and a client connected in sequence, and a camera module, an electronic expansion valve assembly, and a multi-channel capillary tube respectively connected to the main control core board. And control solenoid valve components, refrigerant addition and subtraction control solenoid valve components, cooling and heating control solenoid valve components, power modules, etc. The camera of the camera module is set in front of the laboratory control computer, and the captured image data is sent to the client through the camera module, the main control core board, and the WIFI module.

[0026] In this embodiment, the client can use the mobile phone of the performance designer and is equipped with a WeChat applet, the main control core board can use the STM32F407 single-chip microcomputer, the WIFI module can use the E...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com