Method for testing solid content of lithium ion secondary battery slurry

A test method and secondary battery technology, applied in the field of lithium ion batteries, can solve problems such as large calculation errors, and achieve the effects of high test accuracy, convenient use and improved test efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

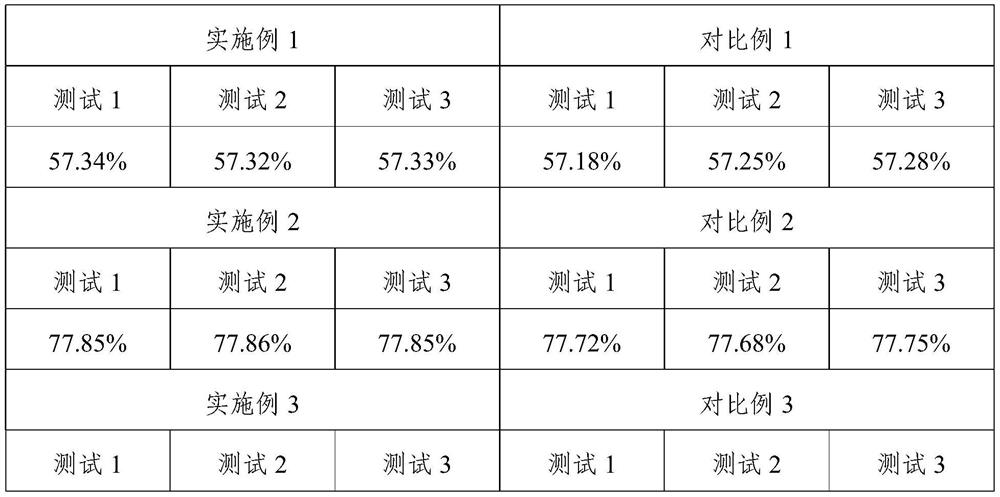

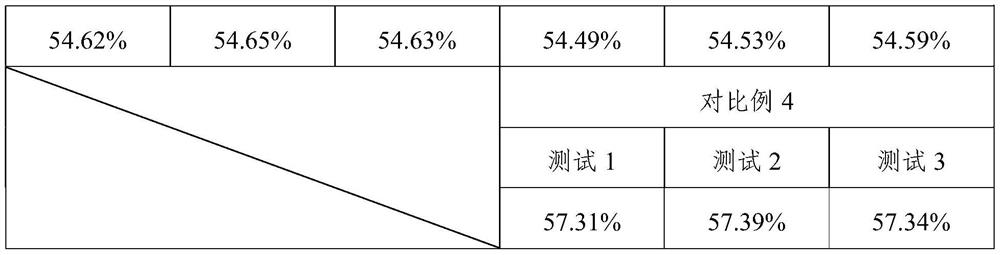

Embodiment 1

[0029] This embodiment provides a method for testing the solid content of lithium-ion secondary battery slurry, comprising the following steps:

[0030] (1) Cut a square piece of foil (the side length is 70mm), weigh it on a balance with an accuracy of one ten-thousandth, and record the weight in m 1 ;

[0031] (2) Place the foil on the operating table, coat the positive electrode lithium iron phosphate slurry to be tested on the surface of the foil, weigh it on a balance with an accuracy of one ten-thousandth, and record the weight as m 2 ;

[0032] (3) Place the foil with slurry on the induction cooker, turn on the induction cooker for heating, first heat at 1000W for 1.5min, then at 1600W for 2min, and finally at 1200W for 0.5min; after the heating is completed, Weigh on a balance with an accuracy of one ten-thousandth, and record the weight as m 3 ;

[0033] (4) Calculate the solid content of the slurry: (m 3 -m 1 ) / (m 2 -m 1 )*100%.

Embodiment 2

[0035] This embodiment provides a method for testing the solid content of lithium-ion secondary battery slurry, comprising the following steps:

[0036] (1) Cut a square piece of foil (the side length is 70mm), weigh it on a balance with an accuracy of one ten-thousandth, and record the weight in m 1 ;

[0037] (2) Place the foil on the operating table, coat the positive electrode ternary material slurry to be tested on the surface of the foil, weigh it on a balance with an accuracy of one ten-thousandth, and record the weight as m 2 ;

[0038] (3) Place the foil with the slurry on the induction cooker, turn on the induction cooker for heating, first heat at 800W for 1min, then at 1800W for 2min, and finally at 1300W for 0.5min; Weigh on a balance with an accuracy of one ten-thousandth, and record the weight in m 3 ;

[0039] (4) Calculate the solid content of the slurry: (m 3 -m 1 ) / (m 2 -m 1 )*100%.

Embodiment 3

[0041] This embodiment provides a method for testing the solid content of lithium-ion secondary battery slurry, comprising the following steps:

[0042] (1) Cut a square piece of foil (the side length is 90mm), weigh it on a balance scale with an accuracy of one ten-thousandth, and record the weight as m 1 ;

[0043] (2) Place the foil on the operating table, coat the negative electrode water-based graphite slurry on the surface of the foil, weigh it on a balance with an accuracy of 1 / 10,000, and record the weight as m 2 ;

[0044] (3) Place the foil with the slurry on the induction cooker, turn on the induction cooker for heating, first heat at 1200W for 2 minutes, then at 2000W for 2 minutes, and finally at 1600W for 0.5min; Weigh on a balance with an accuracy of one ten-thousandth, and record the weight in m 3 ;

[0045] (4) Calculate the solid content of the slurry: (m 3 -m 1 ) / (m 2 -m 1 )*100%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Side length size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com