Auxiliary Tooling for Screening and Testing of Thermistor Chips with Surface Electrodes

A thermistor chip and surface electrode technology, which is used in measurement devices, measurement device housings, and thermometer testing/calibration, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with accompanying drawing:

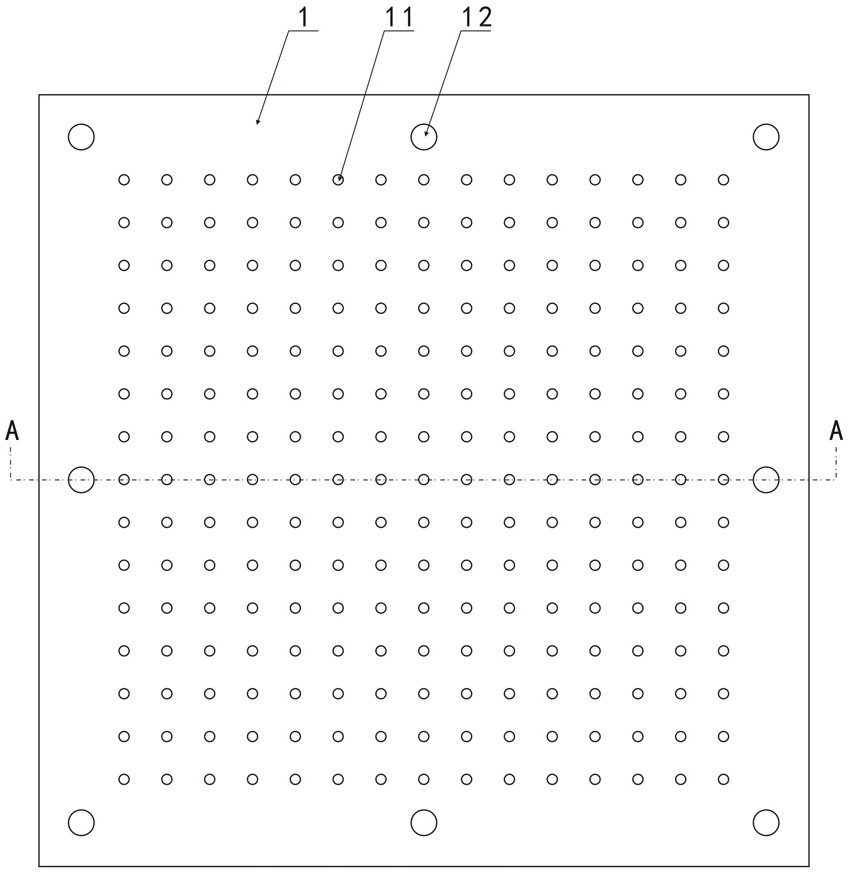

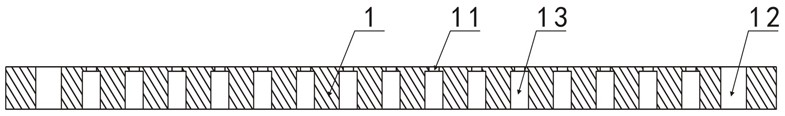

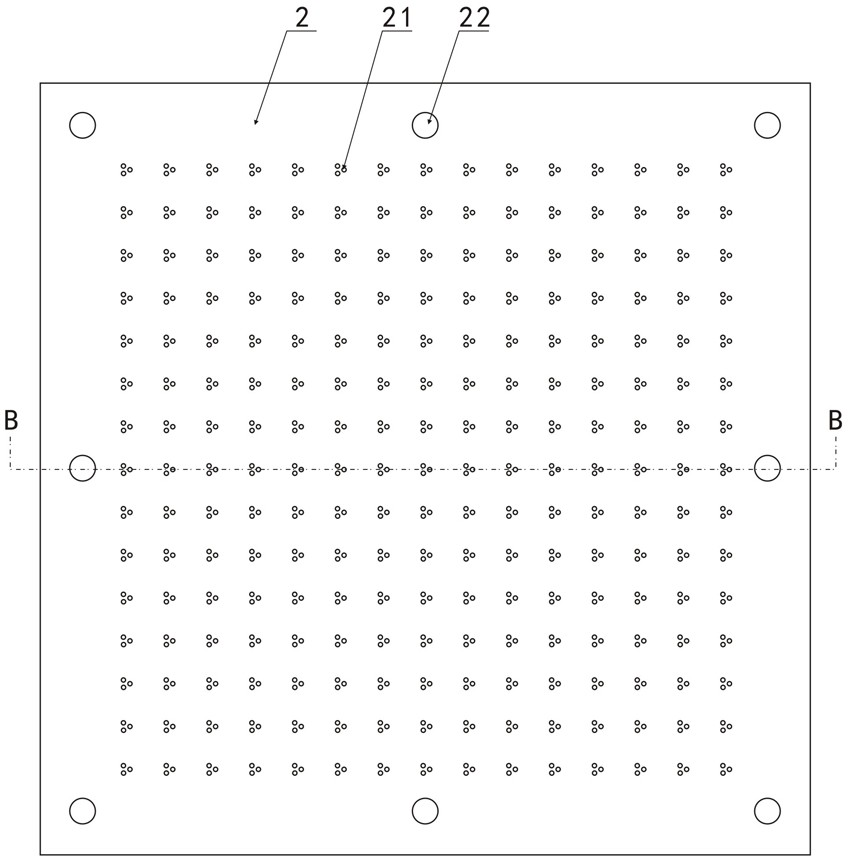

[0036] Such as Figure 1-Figure 8 As shown, the thermistor chip screening test auxiliary tooling with surface electrodes described in the present invention is used to screen the thermistor chips (not shown) with surface electrodes, including conductive and horizontal common electrode plates 2, A horizontal insulating cover plate 1 and an axially vertical metal column 3, the insulating cover plate 1 is provided with a plurality of axially vertical cover plate through holes, and the cover plate through holes include communication connections and overlapping central axes The first through hole 11 and the second through hole 13, the diameter of the first through hole 11 is smaller than the diameter of the second through hole 13, the outer diameter of the metal post 3 is smaller than the diameter of the second through hole 13 and larger than the diameter of the first through hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com