Equipment and method for plating glass antireflective film through chemical vapor deposition process

A technology of chemical vapor deposition and anti-reflection coating, which is applied in the field of on-line coating of glass anti-reflection coating by chemical vapor deposition, which can solve the problems of thin edge thickness of cut-to-length glass, high glass waste rate, and large energy consumption. , to achieve the effect of reducing vacuum energy consumption, low energy consumption and reducing drying process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

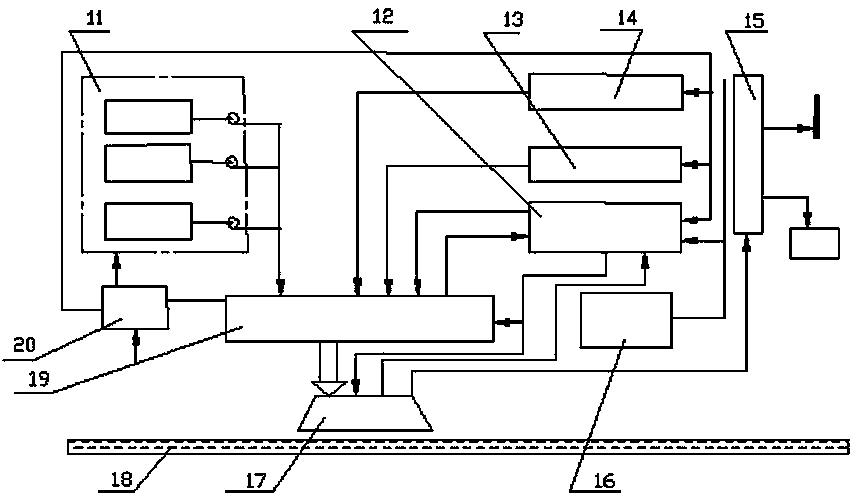

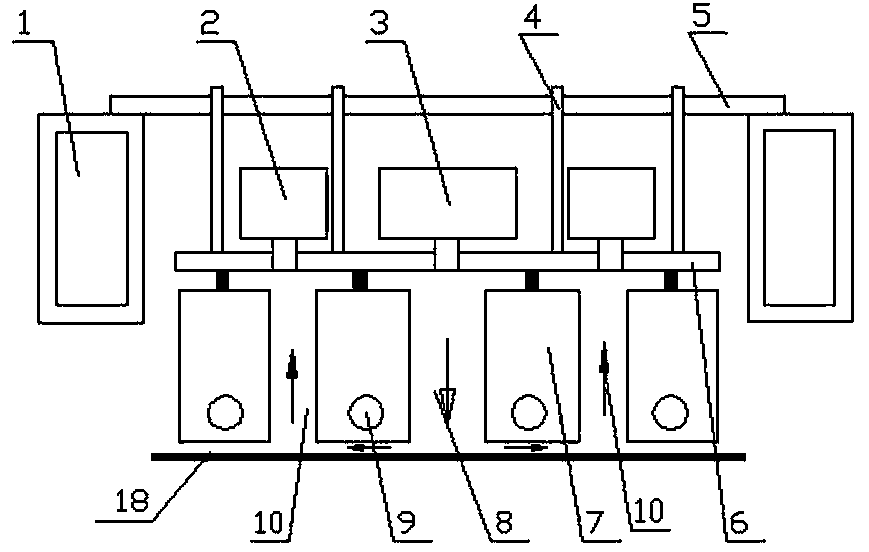

[0089] The width of the glass ribbon is 2400mm, and the pulling speed of the glass ribbon is 280m / hr.

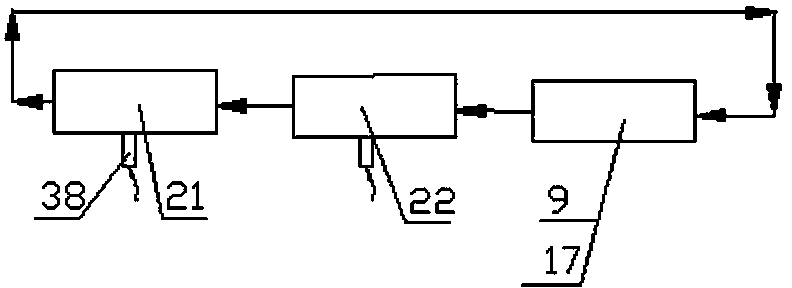

[0090] The prepared glass raw materials are melted and clarified to obtain a high-viscosity glass liquid at 1100°C, and the high-viscosity glass liquid is rolled and formed by a set of engraved alloy steel rollers with a water cooling device inside to obtain a high-temperature glass ribbon of the required thickness 18. The formed glass ribbon is rapidly cooled to 665°C on the inner water-cooled alloy steel roller, and coated with the equipment for coating glass anti-reflection film by chemical vapor deposition method. The main raw material of the anti-reflection film used is tetraethyl silicate Esters, deionized water and air, the dosage of tetraethyl silicate is 8.5Kg / hr; the dosage of deionized water is 0.5Kg / hr; the air flow rate is 58Kg / hr; triethyl phosphate is used as catalyst, and the dosage is 0.9Kg / hr ; Nitrogen is used as the carrier gas with a flow rate of 97Kg / h...

Embodiment 2

[0092] The width of the glass ribbon is 2400mm, the pulling speed is 255m / hr, the temperature of the glass ribbon in the coating area is 680°C, the anti-reflection chemical raw material mainly uses silicon tetrachloride, and the dosage is 12Kg / hr; the dosage of deionized water is 0.72Kg / hr; the catalyst phosphoric acid The amount of triethyl ester is 0.67Kg / hr; the air flow rate is 78Kg / hr; nitrogen is used as the carrier gas, the flow rate is 121Kg / hr, and the air directly enters the coating device nozzle 32 from the dry air supply device.

[0093] All the other are with embodiment 1.

Embodiment 3

[0095] The width of the glass ribbon is 2400mm, the pulling speed is 245m / hr, and the temperature of the glass ribbon in the coating area is 640°C. The raw material of the anti-reflection film is tetraethyl orthosilicate, the dosage is 7.6Kg / hr; the dosage of deionized water is 0.5Kg / hr; the dosage of catalyst triethyl phosphate is 0.7Kg / hr; the air flow rate is 70Kg / hr; The air is 89Kg / hr, and the air enters the cyclone tube 32 from the same direction as the raw material of the liquid-phase anti-reflection film enters.

[0096] All the other are with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

| Mohs hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com