Method for predicting dynamic stiffness of rubber mount

A prediction method and technology of dynamic stiffness, applied in the field of automobile suspension, can solve problems such as weak applicability, and achieve the effects of low prediction cost, convenient and fast prediction method, and good working conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] In the following description, the technical solutions are explained in conjunction with specific illustrations so as to fully understand the application of the present invention. However, the application of the present invention can be implemented in many other ways different from those described here, and similar generalized embodiments made by those skilled in the art without creative work all belong to the protection scope of the present invention.

[0062] The terminology used in the specification is for the purpose of describing particular embodiments only and is not intended to limit the specification. As used in one or more embodiments of this specification and the appended claims, the singular forms "a", "the", and "the" are also intended to include the plural forms unless the context clearly dictates otherwise.

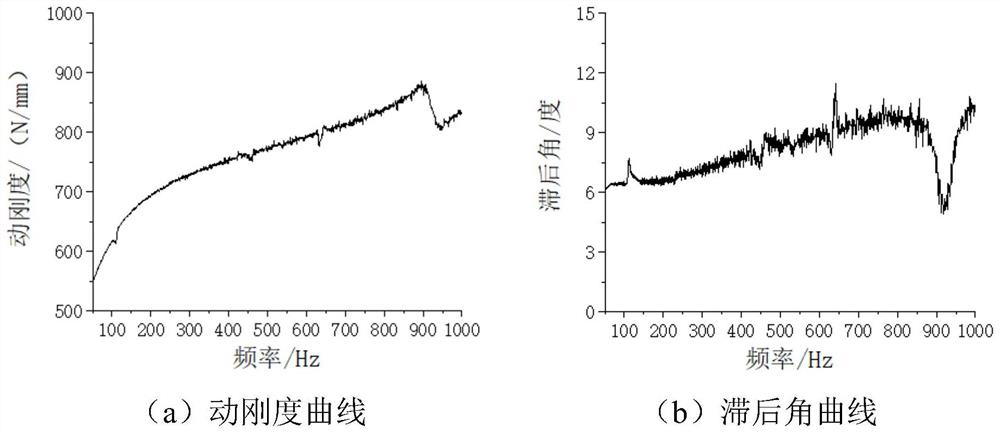

[0063] The invention uses finite element simulation software to simulate the dynamic stiffness curve of the rubber mount to obtain a high-frequency dy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com