Fatigue life analysis method for differential shell of electric drive assembly

A technology of fatigue life analysis and fatigue life, which is applied in the field of fatigue life analysis of the differential case of the electric drive assembly, can solve problems such as large load fluctuations and difficulty in determining the fatigue damage of the differential case, and achieve improved accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

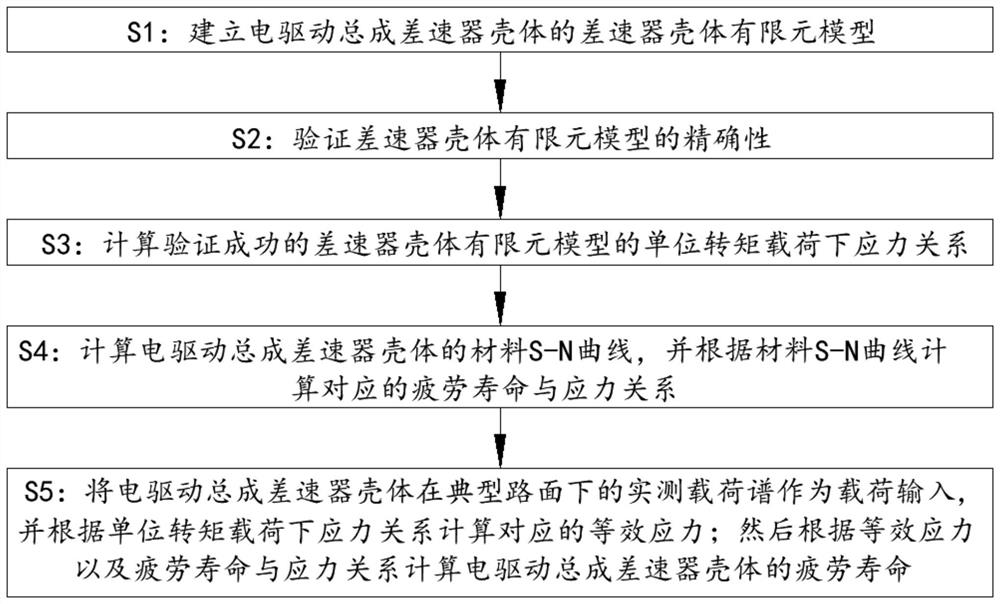

[0062] This embodiment discloses a method for analyzing the fatigue life of the differential housing of the electric drive assembly.

[0063] Such as figure 1 As shown, a fatigue life analysis method for the differential housing of the electric drive assembly includes the following steps:

[0064] S1: Establish the differential case finite element model of the electric drive assembly differential case;

[0065] S2: Verify the accuracy of the differential housing finite element model;

[0066] S3: Calculation and verification of the stress relationship under the unit torque load of the finite element model of the differential case;

[0067] S4: Calculate the material S-N curve of the differential case of the electric drive assembly, and calculate the corresponding relationship between fatigue life and stress according to the material S-N curve;

[0068] S5: Take the measured load spectrum of the differential case of the electric drive assembly under a typical road surface as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com