Device and method for testing frictional angles of small-diameter particles

A testing device and technology of small particle size, applied in the field of physical property detection of granular materials, can solve the problems of artificial error, small scope of application, low measurement accuracy, etc., and achieve the effect of preventing manual error, improving test efficiency and high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

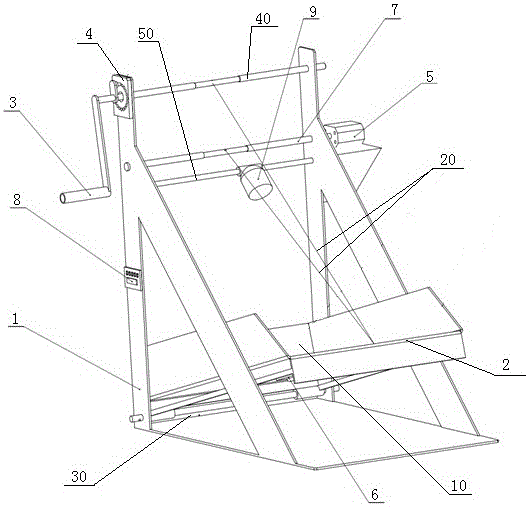

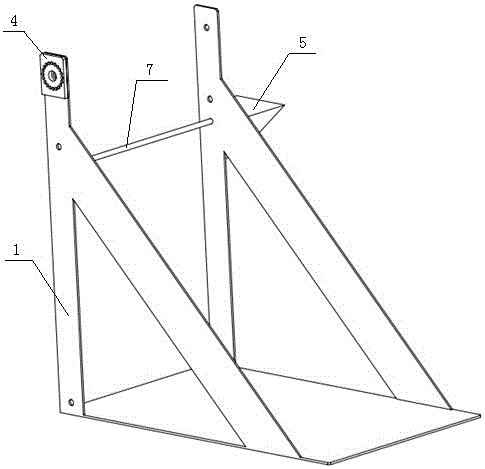

[0043] The schematic diagram of the test device of a kind of small particle diameter particle friction angle of the present embodiment is as Figure 1 to Figure 5 As shown, it includes a controller, a tested board, a bracket 1, a bottom plate 2, a first rotating shaft 7, a driving device 5, a connecting structure 20, an inclination sensor 6, a numerical display module 8 and an image capture device 9, and the tested board It is detachably arranged on the base plate 2, and the driving device 5, the inclination sensor 6, the numerical display module 8 and the image capture device 9 are all connected to the controller; the first rotating shaft 7 is arranged on the bracket 1, and the bottom of the bracket 1 is provided with The rotating shaft 30, one end of the base plate 2 is rotationally connected with the support 1 through the rotating shaft 30, the other end of the base plate 2 can be connected with the first rotating shaft 7 through the connecting structure 20, and the driving ...

Embodiment 2

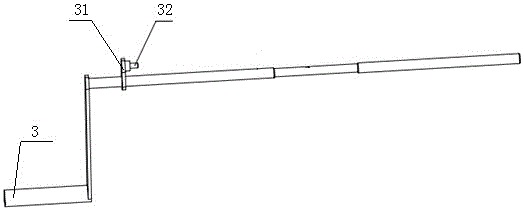

[0057] The schematic diagram of the test device of a kind of small particle diameter particle friction angle of the present embodiment is as Figure 1 to Figure 5 As shown, it includes a controller, a tested plate, a bracket 1, a base plate 2, a handle 3, a second rotating shaft 40, a connecting structure 20, an inclination sensor 6 and a numerical display module 8; the tested plate is detachably arranged on the base plate 2, the inclination sensor 6 and the numerical display module 8 are all connected with the controller; the second rotating shaft 40 is arranged on the support 1, the handle 3 is connected with the second rotating shaft 40, the bottom of the support 1 is provided with the rotating shaft 30, and the bottom plate 2 One end of one end is rotationally connected with the support 1 through the rotating shaft 30, and the other end of the base plate 2 can be connected with the second rotating shaft 40 through the connection structure 20; the inclination sensor 6 is arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com