A highly integrated multi-beam tiled tr component

A high-integration, multi-beam technology, applied in multi-carrier systems, diversity/multi-antenna systems, electrical components, etc., can solve the problems of difficult assembly, low integration, and difficult design, reducing wiring difficulty and improving The effect of integration and solder joint docking operation is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

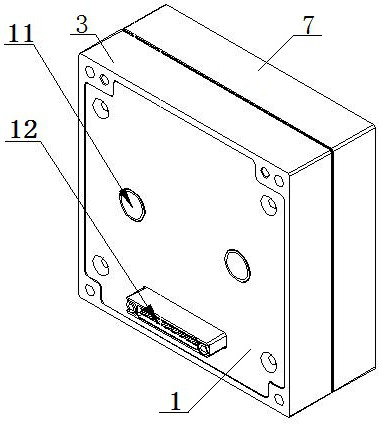

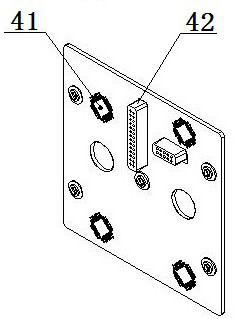

[0034] A highly integrated multi-beam tiled TR component, such as figure 1 , 7 As shown, it includes RF public input port 11, power supply and control connector port 12, cover plate 1, wave control sub-board 2, upper cavity body 3, RF power supply board 4, fur button fixing board 5, RF control board 6 and lower The cavity 7 and the lower cavity 7 are integrated with an antenna output port 71 . The radio frequency common input port 11 is used for radio frequency signal input, and the radio frequency signal input from the radio frequency common input port 11 is carried out multi-beam signal power division, amplitude phase modulation, power amplification by the signal processing circuit on the radio frequency control board 6, and then passes through the antenna output port 71 realizes the output of the radio frequency signal. The power supply and control signals are input through the power supply and control connector port 12, and the power supply and control signals input from...

Embodiment 2

[0036] A highly integrated multi-beam tiled TR component, such as figure 1 , 7 As shown, it includes a radio frequency common input port 11 , a power supply and control connector port 12 , an upper cavity 3 , a lower cavity 7 and a cover plate 1 , and the cover plate 1 is installed on the upper cavity 3 to open. The wave control sub-board 2 is installed in the upper cavity 3 . Both the cover plate 1 and the sub-board 2 are assembled in the upper cavity 3, and the sub-board 2 can be installed inside the upper cavity 3 by screws; the cover plate 1 can be installed in the upper cavity 3 by screws or silver glue.

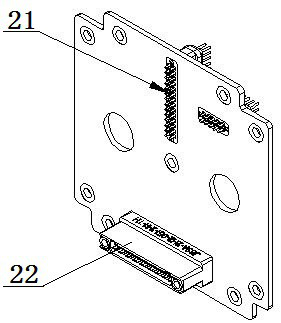

[0037] A radio frequency common input port 11 is integrated on the cover plate 1 for inputting radio frequency signals. The power supply and control connector port 12 is integrated on the wave control daughter board 2, such as figure 2 As shown, the power supply and control connector port 12 is provided with a micro-rectangular connector 22, and the micro-rectangula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com